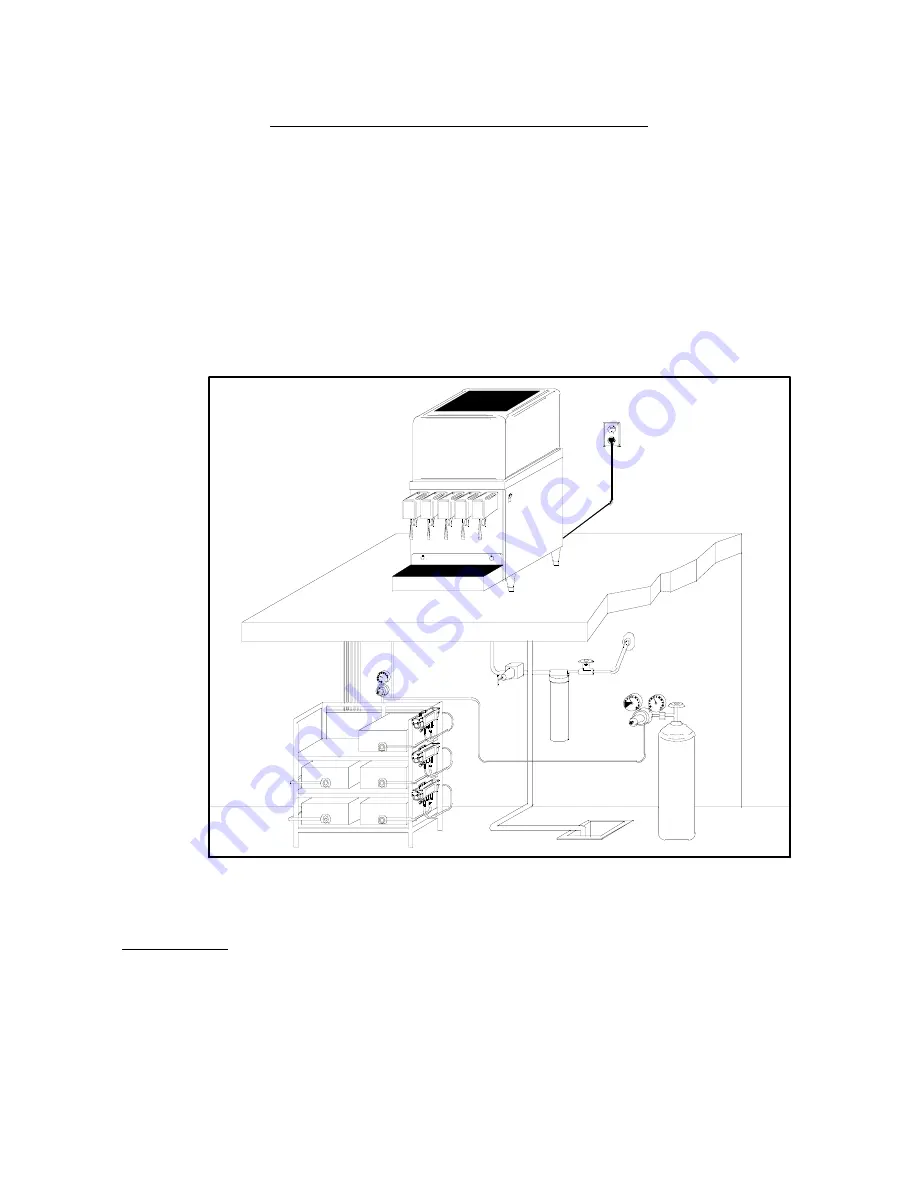

LOCATION RECOMMENDATIONS FOR TOPPER

1.

Position unit as close as possible to proper electrical source, 120V 60HZ.

2.

Position unit with a minimum of 2” space between bulkhead and cabinet for sufficient

ventilation. Allow enough space between ceiling and unit for cover removal.

3.

Position unit as close as possible to water source. Half inch gate valve recommended for

water connection.

4.

Enough space must be allowed to install C02 cylinder, syrup containers, racks, pumps,

water filter, etc.

5.

Position unit as close as possible to floor drain.

FIGURE 2-1. SAMPLE OF POSSIBLE INSTALLATION.

INSTALLATION

1.

Make all connections: C02 gas, plain water and syrups.

2.

Place TOPPER in position. Make sure sufficient space between bulkheads, walls and

overheads is available for proper air circulation around cooling unit.

2-2