Symptom

Problem

Fan overheats, over

amps or runs very

rough

Check with the motor manufacturer to see if the motor is able

to be speed controlled by reducing the input voltage. Verify

the motor is a single phase PSC motor.

The fan cycles from

full ON to full OFF

with little or no

modulation

Check the Hard start setting in the App. Too much hard start

can drop pressure too quick causing a fan cycling effect.

Lower the hard start in the App.

Should the fan cycling persist, move the probe up several

bends into the condenser to increase the sensitivity to the

condensing temperature.

Adjust the minimum output voltage in the App while fine

tuning the probe placement on the condenser.

The fan does not

come on at all

Using an AC voltmeter, measure the voltage between the 24

VAC terminals. It should read approximately 24 volts.

Measure the line voltage between LINE 1 and LINE 2 to confirm

that line voltage is present. Check Line 1 of the ICM325A

and confirm it is connected to the same leg of power as the

common of the Run capacitor.

Remove the thermistor probe from the terminal block and

measure its resistance at ambient temperature. Compare your

reading at the appropriate temperature in Appendix B to see

if the actual resistance approximates the listed value. Next,

hold the probe in your hand and confirm that the resistance

decreases. If a pressure sensor is used, measure the DC

voltage between GND and the sensor output at BWG and

compare your reading to the expected pressure in Appendix A.

The high pressure

switch trips off

Move the probe further into the condenser where the

temperature is higher. This will produce a higher fan RPM and

will decrease the head pressure.

Fine adjust the cutout and hard start settings in the App.

GREEN

AMBER

Condition

OFF

OFF

• No voltage at L1 or L2

• No control voltage when jumper is placed

• Output is off

ON

OFF

Full Speed Operation

OFF

ON

Variable Speed Operation

OFF

2 Flashes

Shorted Sensor (Temperature or Pressure)

OFF

3 Flashes

Open Sensor (Temperature or Pressure)

TROUBLESHOOTING

LED DIAGNOSTIC INDICATORS

APPENDIX A

APPENDIX B

TEMPERATURE VS. PROBE RESISTANCE

°C

°F

Resistance (KΩ)

0°

32°

32.7

5°

41°

25.4

10°

50°

19.9

15°

59°

15.7

20°

68°

12.5

25°

77°

10.0

30°

86°

8.1

35°

95°

6.5

40°

104°

5.3

45°

113°

4.4

50°

122°

3.6

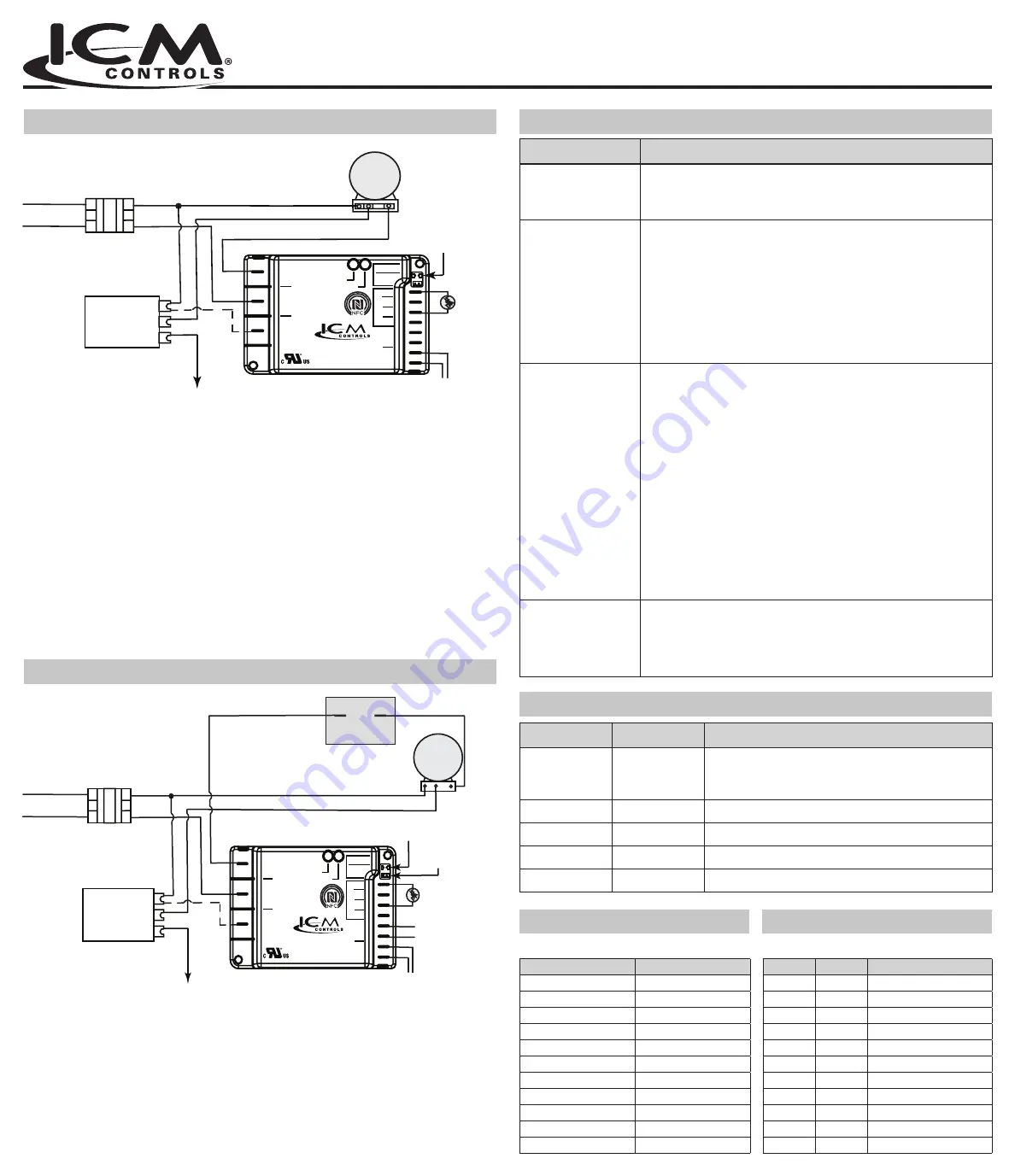

Wiring of the ICM325A to a heat pump is the same as for air conditioning with the

exception of the Motor 2 output and the reversing valve input. For a heat pump, the

ICM325A Motor 2 terminal is connected to the outdoor fan relay input power terminal

(com) on the defrost board. The condenser fan common remains connected to the

normally closed terminal of the fan relay on the defrost board. Apply the reversing

valve voltage to the HP RV input in parallel with the existing reversing valve; for cool

active reversing valves a jumper will have to be placed at the HP O RV jumper posi-

tion. NOTE: Line one of the ICM325A must share the same leg of power that is feed-

ing the common of the run capacitor.

AIR CONDITIONING SYSTEM WIRING

HEAT PUMP SYSTEM WIRING

Connect the wires from the contactor (load side), run capacitor, and the condenser

fan as shown in diagram above. If control voltage is desired, ensure the jumper is

placed on the control voltage enable input and the proper voltage (24-240 VAC) is

applied to the control voltage input. Place the temperature probe at T1/P1 and 5V and

mount the probe on a U-bend in the upper third of the condenser. If two temperature

probes are needed, wire the additional temperature probe to T2/P2 & 5V. If a pressure

transducer is used, mount the transducer on the discharge line at the service fitting.

Connect the red wire to +5V, the black wire to GND and the BWG (blue/white/green)

wire to T1/P1 input. If two pressure sensors are used, connect the black and red wires

of the additional pressure sensor to the same points as previously mentioned and

connect the BWG (blue/white/green) wire to TP2/P2. NOTE: Line one of the ICM325A

must share the same leg of power that is feeding the common of the run capacitor.

Pressure (PSIG)

Voltage (VDC)

15

0.5

50

0.8

100

1.2

150

1.6

200

2.0

250

2.4

300

2.8

350

3.2

400

3.6

450

4.0

515

4.5

PRESSURE VS. VOLTAGE

MOTOR 2

ICM325A

LINE 2

LINE 1 / MOTOR 1

120 - 600 VAC

FULL SPEED

VARIABLE SPEED

CONTROL

INPUT

24-240VAC

HP RV

24-240VAC

GND

+5V

T2/P2

T1/P1

CONTROL INPUT

HP

MADE IN THE USA

SENSOR

ENABLE

Line Voltage

120-600 VAC

Place jumper to enable

the control voltage input

24-240 VAC

Control Voltage

(optional)

Temperature

Sensor

O RV

Run

Start

Common

L1

L2

T1

T2

Contactor

Run

Capacitor

To C

ompr

es

sor

Field

Ins

tal

led

W

ire

Com

Herm

Fan

Single

Phase PSC

Fan Motor

MOTOR 2

ICM325A

LINE 2

LINE 1 / MOTOR 1

120 - 600 VAC

FULL SPEED

VARIABLE SPEED

CONTROL

INPUT

24-240VAC

HP RV

24-240VAC

GND

+5V

T2/P2

T1/P1

CONTROL INPUT

HP

MADE IN THE USA

SENSOR

ENABLE

Line Voltage

120-600 VAC

Fan

Relay

Place jumper to enable

the control voltage input Place jumper to

enable a cool active

reversing valve at

the HP O RV input

24-240 VAC

reversing valve

input (heat active

default)

24-240 VAC

Control Voltage

(optional)

Temperature

Sensor

Defrost Board

COMN

Run

Start

Common

C

L1

L2

T1

T2

Contactor

Run

Capacitor

To C

ompr

es

sor

Field

Ins

tal

led

W

ire

Com

Herm

Fan

Single

Phase PSC

Fan Motor

O RV