Two- Stage Multi Position Furnace

Service Manual

27

440 08 2002 02

2 SPEED MODELS - P.S.C. MOTOR

HEATING SPEEDS

Should it be necessary to change blower speeds to obtain

proper temperature rise on either (or both) High fire, and/or

Low Fire, Simply take the appropriate speed tap wire, and

plug it on to the terminal marked “HEAT HIGH” or “HEAT

LOW” respectively on the HONEYWELL ST9162A control.

Figure 37

2 Speed Models

Blower Speed Taps

Wire Color

Motor Speed

Black

High

Orange

Medium--High

Blue

Medium--Low

Red

Low

COOLING SPEED

When the proper speed has been determined, simply plug

it on to the terminal marked ”COOL” on the HONEYWELL

ST9162A control.

“M1 ” & “M2 ” TERMINALS

There are two (2) terminals (marked “M1” & “M2”) on the

HONEYWELL ST9162A control which have no internal

connection to the control. Their purpose is to provide a

place to connect, or “PARK” any “UNUSED” speed tap

wires (P.S.C. motors ONLY) to keep them out of the way

and prevent them from shorting out against the furnace

casing, or each other.

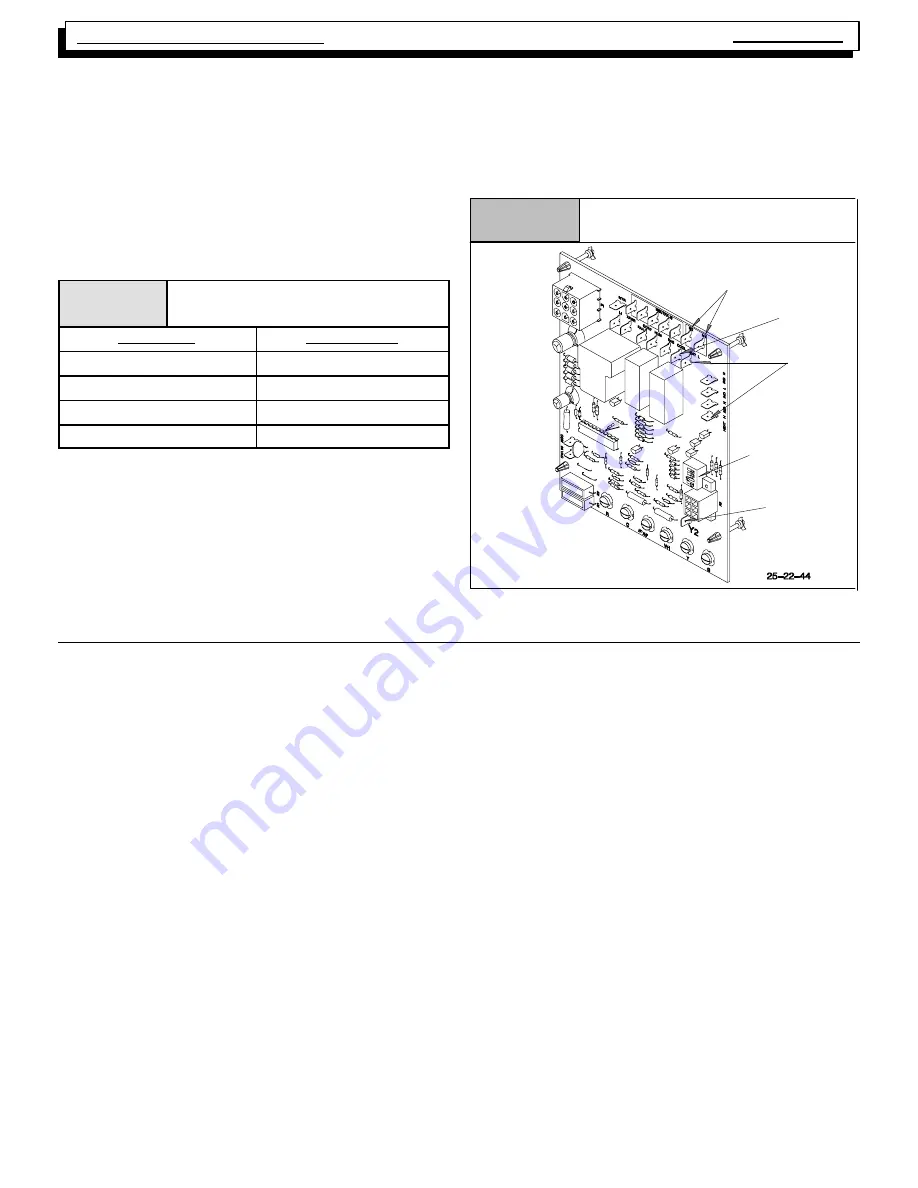

Figure 38

Honeywell ST9162

Dip Switch

Y2 Terminal

M1 & M2 Terminals

Cooling

Terminal

Heating

Terminals

27. BLOWER ROTATION

·

The startup of a furnace will involve a cycle or two of the fur-

nace to properly prime the condensate trap with water. Until

the trap is fully primed, some condensate will be pulled into

the combustion blower. The furnace may cycle on the pres-

sure switch connected to the plastic transition box due to con-

densate buildup. After the trap is primed, the condensate will

start draining from the furnace. The combustion blower will

clear out any remaining condensate in the blower housing

through the vent fitting downstream of the blower. Note that

the condensate trap can also be primed by pouring water into

the vent drain side of the trap. Remove the small plastic cap

and clamps from the unused drain stub on the vent drain side

of the condensate trap. Connect a section of the

5

/

8

²

OD hose

with a funnel to the drain stub and pour eight (8) ounces of wa-

ter into the trap. Remove the hose and replace the plastic cap

and clamp. This will prime both the vent and the transition

sides of the trap.

·

The startup of a furnace will have “milky or oily”. looking con-

densate coming from the furnace. This is residual drawing

lube in the secondary heat exchanger that is being washed

out by the condensate. The condensate will clear up as the

furnace operates. Poisonous carbon monoxide gas hazard.

·

The use of a vent tee at the outlet of the condensate trap is not

required if the condensate drain line from the trap to the open

drain is properly sloped (

1

/

4

²

per foot downward slope). Do

not trap the drain line in any other location than at the conden-

sate trap.

·

The combustion blowers and blower gaskets are different on

some of the furnace models. There are two part numbers of

the combustion blower for the 2--stage furnace models. (See

the

Tech. Manual

for the correct part number for the furnace.)

Besides the part number difference, the 50M, 75M and 100M

BTUH models use the shaded pole motor version with the

1

7

/

8

²

diameter back plate with a raised lip. The blower gasket

is approximately 2

3

/

4

²

outside diameter and is positioned into

the recessed opening in the transition. The 125M BTUH mod-

els use the PSC motor version with the 2

²

diameter back plate

with no lip. The blower gasket is approximately 3

1

/

4

²

outside

diameter and is positioned on the flat surface of the transition.

A mismatch of blower backplated and/or gaskets can cause

the furnace to cycle on the pressure switch or to not operate.

This could be misread as a condensate drainage problem.