4

IMPORTANT:

All local and national code require-

ments governing the installation of oil burning

equipment, wiring and flue connections must be

followed. Some of the codes that may be applicable

are:

CSA B139

INSTALLATION CODE FOR OIL

BURNING

EQUIPMENT

ANSI/NFPA 31

INSTALLATION OF OIL BURNING

EQUIPMENT

ANSI/NFPA 90B WARM AIR HEATING AND AIR

CONDITIONING

SYSTEMS

ANSI/NFPA 211 CHIMNEYS, FIREPLACES, VENTS

AND SOLID FUEL BURNING

APPLIANCES

ANSI/NFPA 70

NATIONAL ELECTRICAL CODE

CSA C22.2 No.3 CANADIAN ELECTRICAL CODE

Only the latest issues of the above codes should be

used, and are available from either:

The National Fire Protection Agency

1 Batterymarch Park

Quincy, MA 02269

or

The Canadian Standards Association

178 Rexdale Blvd.

Rexdale, Ontario M9W 1R3

1.2) GENERAL

This central heating unit is a true multi-position unit, in that it

can operate in four different configurations

when used with

a chimney

, i.e., upflow, counter flow (downflow), and

horizontal (both left-to-right and right-to-left airflow).

Very few modifications are required during installation, to

change the furnace from one configuration to another. The

furnace is shipped in the upflow configuration; however,

instructions on how to change to the other configurations are

included in this manual.

CAUTION

This unit can only be installed in an upflow configuration if a

Sealed Combustion System (SCS) is used with it.

The furnace is shipped complete with burner and controls. It

requires a 115VAC line voltage connection to the control

panel, thermostat hook-up as shown on the wiring diagram,

one or more oil line connections, suitable ductwork and

connection to a properly sized vent.

The air handling capacity of this furnace is designed for

cooling as well. Refer to Table 4 for the expected airflow at

various external static pressures.

1.3) LOCATION

The unit must be installed in a location where the ambient

and return air temperature is over 15°C (60°F).

WARNING

This furnace is not watertight and is not designed

for outdoor installation. This furnace shall be

installed in such a manner as to protect the

electrical components from water. Outdoor

installation will lead to a hazardous electrical

condition and to premature furnace failure.

CAUTION

If this furnace is installed in an attic, it is important

to keep insulation at least 0.3 m (12") away from

any furnace openings. Some types of insulating

material may be combustible.

This furnace is approved for reduced clearances to

combustible construction. Therefore, it may be installed in a

closet or similar enclosure. As this unit may be installed as

an upflow, counter flow, or horizontal furnace, it may be

located in a basement, on the same level as the area to be

heated, suspended, or in a crawlspace. In any case, the unit

should always be installed level.

In a basement, or when installed on the floor (as in a

crawlspace), it is recommended that the unit be installed on

a concrete pad that is 25.4 mm to 50.8 mm (1

"

to 2

")

thick.

When installed in the counter flow position, this furnace must

not be installed on combustible flooring, unless the approved

sub-base is used (Model # DFB-101). Since the flue pipe is

in counter flow position, be sure that the clearances from the

flue pipe to combustible construction are maintained. Also, it

is recommended to use the flue pipe protection kit FPG-101

or FPG-102. Refer to Figure 1 and the installation

instructions included with the kit.

FIGURE 1

DNS-0278 Rev. A

Summary of Contents for AMP105-IE2

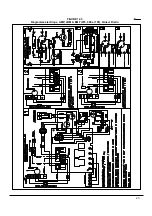

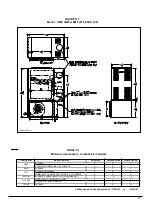

Page 20: ...FIGURE 12 1 Diagramme lectrique AMP LBM BMF 075 090 et 105 br leur Beckett 21...

Page 21: ...FIGURE 12 2 Diagramme lectrique AMP LBM BMF 120 140 et 155 br leur Beckett 22...

Page 22: ...FIGURE 12 3 Diagramme lectrique AMP LBM BMF 075 090 et 105 br leur Riello 23...

Page 23: ...FIGURE 12 4 Diagramme lectrique AMP LBM BMF 120 140 et 155 br leur Riello 24...

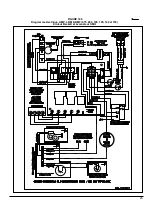

Page 26: ...FIGURE 12 7 Diagramme lectrique AMP LBM BMF 075 090 et 105 br leur B SCS 27...

Page 27: ...FIGURE 12 8 Diagramme lectrique AMP LBM BMF 120 140 et 155 br leur B SCS 28...

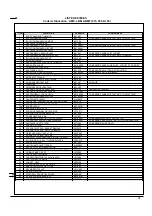

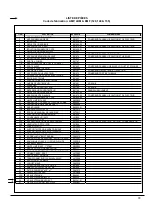

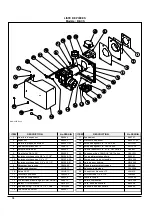

Page 28: ...29 COMPOSANTES ET PI CES DE REMPLACEMENT...

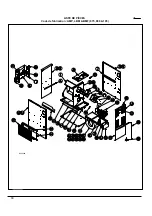

Page 29: ...LISTE DE PI CES Code de fabrication AMP LBM BMF 075 090 105 30 B50058A...

Page 31: ...LISTE DE PI CES Code de fabrication AMP LBM BMF 120 140 155 32 50062A...

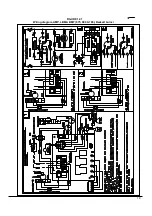

Page 51: ...19 FIGURE 12 1 Wiring diagram AMP LBM BMF 075 090 105 Beckett burner...

Page 52: ...20 FIGURE 12 2 Wiring diagram AMP LBM BMF 120 140 155 Beckett burner...

Page 53: ...21 FIGURE 12 3 Wiring diagram AMP LBM BMF 075 090 105 Riello burner...

Page 54: ...22 FIGURE 12 4 Wiring diagram AMP LBM BMF 120 140 155 Riello burner...

Page 57: ...FIGURE 12 7 Wiring diagram AMP LBM BMF 075 090 105 B SCS burner 25...

Page 58: ...FIGURE 12 8 Wiring diagram AMP LBM BMF 120 140 155 B SCS burner 26...

Page 59: ...27 COMPONENTS AND REPLACEMENT PARTS...

Page 60: ...PARTS LIST Model AMP LBM BMF 075 090 105 28 B50058A...

Page 62: ...PARTS LIST Model AMP LBM BMF 120 140 155 30 B50062A...