441 01 2314 06

Specifications are subject to change without notice.

21

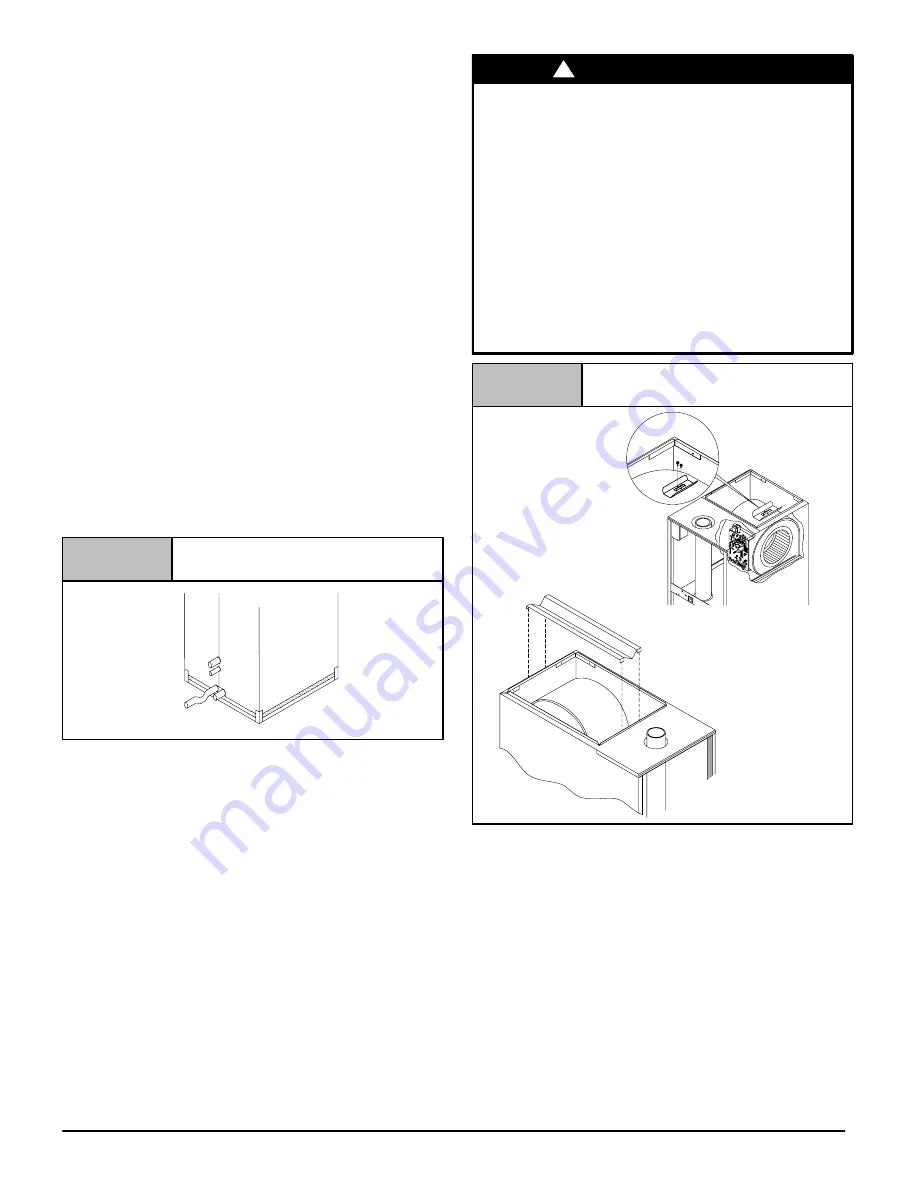

Sub-base for Combustible Floors- Downflow Coil

Adapter Box

The subbase for combustible floors is required when a downflow

furnace,

used with a downflow coil box

, is set on combustible

flooring.

NOTE:

Supply opening is 3

7

/

8

″

(98.4mm) from the rear of the fur-

nace. Therefore maintain a 3

7

/

8

″

(98.4mm) clearance from wall

(where applicable).

1. Cut the opening in the floor according to the dimensions in

Table 4

because the base is equipped with locating tabs that

center the base over the opening.

The opening in the base is 1

1

/

4

″

(31.75mm) shorter and 1

1

/

8

″

(28.6mm) narrower than the minimum required size of the

opening in the floor. This is done to maintain a 1

″

(25.4mm)

clearance between the floor and the plenum.

2. Fabricate the plenum to the dimensions in

Table 4

. Note that

the dimensions given are outside dimensions.

3. Set the base over the opening in the floor, centering the open-

ing in the base over the opening in the floor. Fasten the base to

the floor with screws or nails. See

Figure 14

and

Figure 15.

4. Drop the plenum through the opening in the base. The flange

of the plenum should rest on top of the combustible floor base.

Consideration must be given to the height of the base to allow for

easy installation of the condensate drain. See

Figure 16

. This

subbase for combustible floors has been designed so that the

height of the subbase raises the downflow coil off the floor to allow

easy installation of the condensate drain.

25

−

20

−

52

Condensate Line Raised by Base

Figure 16

Non-Combustible Floor:

Set the furnace over the opening in the floor. If necessary, grout

around the base to seal air leaks between the base and the floor.

Filters:

A filter MUST be used.

The 18

1

/

4

″

X 15

3

/

4

″

(463.5 x 400.1mm) framed high

−

velocity filters

supplied with the furnace may be installed in the return air plenum

above the furnace. A filter rack is supplied with each furnace. See

Figure 17.

Use either filter type:

•

Washable, high

−

velocity filters are based on a maximum air

flow rating of 600 FPM (3.0 m/s).

•

Disposable, low velocity filters are based on a maximum air

flow of 300 FPM (1.5 m/s) when used with external filter grille.

•

See

Circulation Air Blower Data

for additional information.

!

REDUCED FURNACE LIFE HAZARD

Failure to follow this caution may result in reduced

furnace life.

Use of excessively dirty and/or restrictive air filters

may increase furnace operating

temperatures and shorten the life of the furnace.

Filters supplied with the furnace are rated at a

maximum of 600 FPM (3.0 m/s) air velocity and sized

for the furnace’s airflow rate. Replacement filters

must be of equivalent type, size, and rating except as

described below.

Disposable, low

−

velocity filters may be used to

replace washable, high

−

velocity filters, providing

they are sized for 300 FPM (1.5 m/s) or less.

CAUTION

Figure 17

Filter Rack Installation

25-25-14a

OR

Version “A”

factory

−

attached to the

top of the blower housing

Version “B”

factory

−

supplied

but field installed

NOTE

: The return air plenum

MUST

extend a sufficient height

above the furnace (dimension “A” in

Figure 18

) to provide for the

attachment of a return air duct or grille above the filters.

NOTE

: Plenum must be fitted as close to the return air flange of the

furnace as possible to eliminate any air bypassing the filters.

Filters can only be installed through the right hand side of the fur-

nace blower opening. Slide filter into furnace until it is in position to

be pushed up and over into place on the left hand side of furnace.

See

Figure 18

.

Slide remaining filter into furnace and up into place on right hand

side of furnace. See

Figure 18

.

If there is insufficient plenum height for this type of installation, fil-

ters may be installed in any accessible location in the return air

system. In such a case, the filters should be of equivalent size and

style as originally supplied with the furnace.