8

440 04 2023 02

Specifications are subject to change without notice

TECHNICAL SUPPORT

Manufacturers Number (Mfr No --

See Rating Plate

)

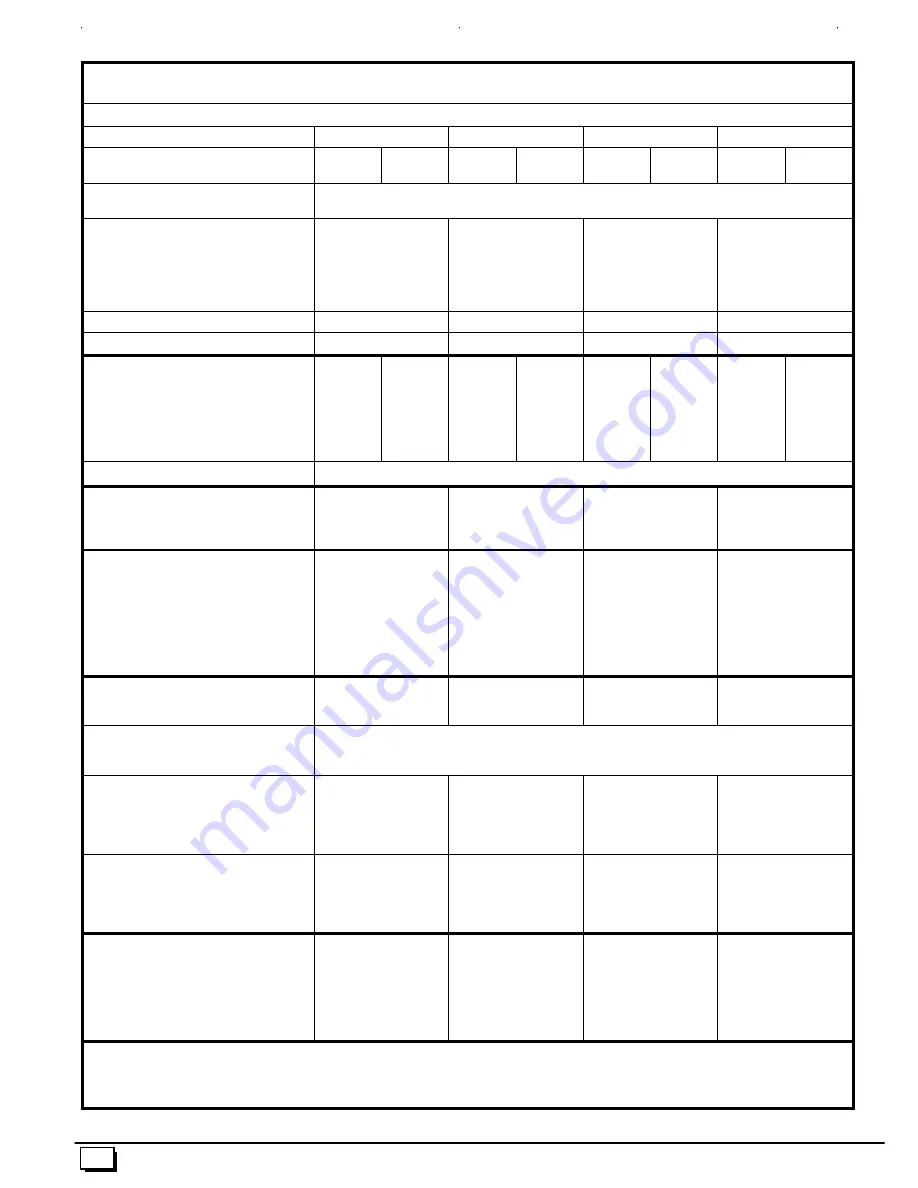

ALL Models

Specifications

*9MPV050F12

*9MPV075F12

*9MPV100J20

*9MPV125L20

General

Gas Type

Nat

Propane

Nat

Propane

Nat

Propane

Nat

Propane

Transformer Size (VA)

T’stat Heat Anticipator

40

.50

Input (Btuh) Std/Alt.

HI Heat

LO Heat

Output (Btuh) Std/Alt.

HI Heat

LO Heat

Temp. Rise (

o

F/

o

C)

HI Heat

LO Heat

50,000

35,000

46,000

32,000

35--65/19--46

35--65/19--46

75,000

52,500

70,000

48,000

40--70/22--38

40--70/22--38

100,000

70,000

93,000

65,000

40--70/22--38

40--70/22--38

125,000

87,500

118,000

82,000

40--70/22--38

40--70/22--38

Electrical (Volts/Hz)

115/60

115/60

115/60

115/60

Rating Plate Amps

9.5

11.4

14.6

15.4

Gas & Ignition

Gas Type

Std. Main Orifices (No/Size)

Gas Valve Honeywell

Regulation Type

Manifold Press.

HI Heat (in wc)

LO Heat (in wc)

Nat.

2/42

VR8205Q

SNAP

3.5

1.7

Propane

2/54

VR8205Q

SNAP

10.0

4.9

Nat.

3/42

VR8205Q

SNAP

3.5

1.7

Propane

3/54

VR8205Q

SNAP

10.0

4.9

Nat.

4/42

VR8205Q

SNAP

3.5

1.7

Propane

4/54

VR8205Q

SNAP

10.0

4.9

Nat.

5/42

VR8205Q

SNAP

3.5

1.7

Propane

5/54

VR8205Q

SNAP

10.0

4.9

Ignition Type

Hot Surface

Combustion

Flue Outlet Size (Inches)

Std. Outlet Temp

(less than)

Comb. Blower (MFD/Volts)

2

140

o

F/60

o

C

4/370

2

140

o

F/60

o

C

4/370

3

140

o

F/60

o

C

4/370

3

140

o

F/60

o

C

4/370

@ Blower

/

@ Transition Box (HI Heat)

Std. Pressures (in wc)

5

′

No Elbows

40

′

+5--90

°

DWV Elbows

@ Blower

/

@ Transition Box (LO Heat)

Std. Pressures (in wc)

5

′

No Elbows

40

′

+5--90

°

DWV Elbows

--1.80

/

--2.60

--1.30

/

--2.30

--1.20

/

--1.90

--1.00

/

--1.80

--1.80

/

--2.60

--1.30

/

--2.30

--1.20

/

--1.90

--1.00

/

--1.80

--1.80

/

--2.60

--1.70

/

--2.50

--1.20

/

--1.90

--1.00

/

--1.80

--1.80

/

--2.60

--1.70

/

--2.50

--1.30

/

--2.30

--1.20

/

--2.20

Limits & Controls

Rollout Switch (

o

F/

o

C)

Limit Control Setting (

o

F/

o

C)

300/149

260/127

300/149

210/99

300/149

240/116

300/149

190/88

Furnace Control (Type)

Furnace Control

On

(Timed--secs)

Off

Integrated

30 HI /45 LO

60,100,140,180

Std. Pressure Sw. (Part No)

(HI Heat)Blwer Switch Press (Close)

Blower Switch Pressure (Open)

(LO Heat)Trans Switch Press (Close)

Transition Switch Pressure (Open)

1013515

0.95

0.80

1.70

1.50

1013515

0.95

0.80

1.70

1.50

1013515

0.95

0.80

1.70

1.50

1013166

1.30

1.10

1.80

1.60

High Altitude Pressure Sw. (Part No)

(HI Heat)Blwer Switch Press (Close)

Blower Switch Pressure (Open)

(LO Heat)Trans Switch Press (Close)

Transition Switch Pressure (Open)

1013165

0.70

0.55

1.40

1.20

1013165

0.70

0.55

1.40

1.20

1013165

0.70

0.55

1.40

1.20

1013157

0.85

0.70

1.70

1.50

Blower Data

Wheel Size (D x W inches)

FLA Motor Amps/Max RPM

Motor Type/H.P.

Filter Type & Size (qty.) Permanent -- supplied

Min. Cool Cap. (Tons)

Max. Cool Cap. (Tons)

11 x 8

7.7/1240

ECM/

1

/

2

16x25x1

1.5

3

11 x 10

9.6/1240

ECM/

3

/

4

16x25x1

1.5

3

11 x 10

12.8/1240

ECM/1

16x25x1 (2)

2

5

11 x 10

12.8/1240

ECM/1

16x25x1 (2)

2

5

Gas Conversion Kits All Models

Nat to Propane

NAHA002LP (1172959*)

Propane to Nat

NAHA002NG (1172961*)

*Order from Service Parts