INSTALLATION INSTRUCTIONS

R

−

410A Split System Air Conditioner

6

421 01 5104 02

Specifications subject to change without notice.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

The unit cabinet must have an uninterrupted or

unbroken ground to minimize personal injury if an

electrical fault should occur. The ground may consist

of electrical wire or metal conduit when installed in

accordance with existing electrical codes.

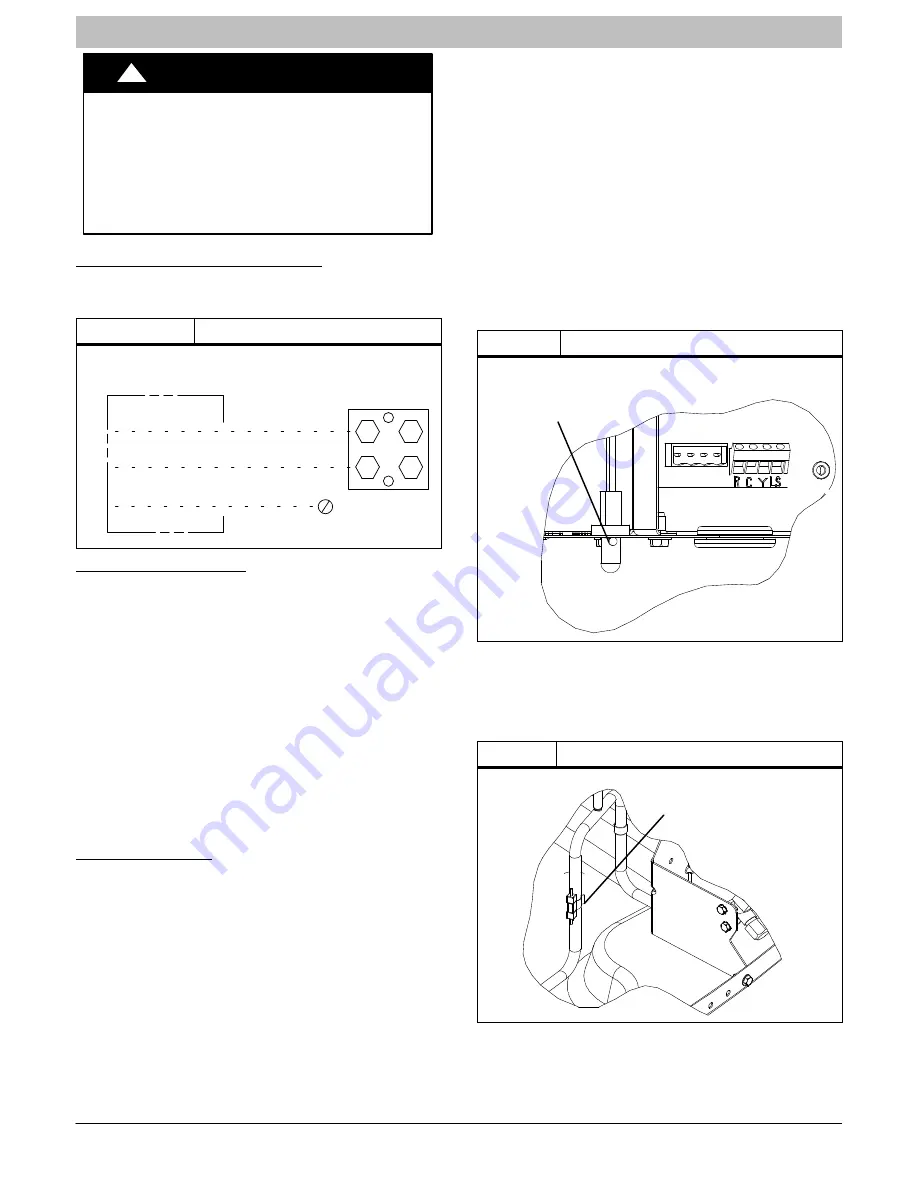

Connect Ground and Power Wires

Connect ground wire to ground connection in control box for

safety. Connect power wiring to contactor as shown in Fig. 5.

Figure 5

Line Power Connections

DISCONNECT

PER N. E. C. AND/OR

LOCAL CODES

CONTACTOR

GROUND

LUG

FIELD GROUND

WIRING

FIELD POWER

WIRING

Connect Control Wiring

Route 24

−

v control wires through control wiring grommet and

connect leads to control wiring. (See Fig. 10 & Fig. 11)

Use No. 18 AWG color

−

coded, insulated (35

_

C minimum)

wire. If thermostat is located more than 100 ft. (30.48 m)

from unit, as measured along the control voltage wires, use

No. 16 AWG color

−

coded, insulated wire to avoid excessive

voltage drop.

All wiring must be NEC Class 1 and must be separated from

incoming power leads.

Use furnace transformer, fan coil transformer, or accessory

transformer for control power, 24

−

v/40

−

va minimum.

NOTE

: Use of available 24

−

v accessories may exceed the

minimum 40

−

va power requirement. Determine total

transformer load and increase the transformer capacity or

split the load with an accessory transformer as required.

Final Wiring Check

IMPORTANT

: Check factory wiring and field wire

connections to ensure terminations are secured properly.

Check wire routing to ensure wires are not in contact with

tubing, sheet metal, etc.

Compressor Crankcase Heater

When equipped with a crankcase heater, furnish power to

heater a minimum of 24 hr before starting unit. To furnish

power to heater only, set thermostat to OFF and close

electrical disconnect to outdoor unit.

A crankcase heater is required for low

−

ambient cooling or if

refrigerant tubing is longer than 80 ft. (24.38 m). Refer to the

Long Line Applications Guideline

−

Residential Split

−

System

Air Conditioners and Heat Pumps Using R

−

410A Refrigerant.

Install Electrical Accessories

Refer to the individual instructions packaged with kits or

accessories when installing.

Check OAT Thermistor and OCT Thermistor

Attachments

Outdoor Air Temperature (OAT) Thermistor is factory installed

by inserting the nibs on either sides of the thermistor body

through a keyhole in the bottom shelf of the control box and

locking it in place by turning it 90 degrees, such that the

spherical end of a nib faces the front of the control box.

Check to make sure the OAT is locked in place. See Fig. 6.

Figure 6

Outdoor Air Thermistor (OAT) Attachment

OAT Thermistor must be locked in place

with spherical nib end facing towards

the front of the control box

DX+ DX- C R

The Outdoor Coil Temperature (OCT) Thermistor is factory

installed on the liquid tube between the coil assembly and the

liquid service valve. See Fig. 7.

Check to make sure the thermistor is securely attached on

the liquid tube with the clip as shown in Fig. 7.

Figure 7

Outdoor Coil Thermistor (OAT) Attachment

OCT Thermistor must be

secured tight on the liquid tube.