SERVICE AND TECHNICAL SUPPORT MANUAL

Gas Furnace: F9MES

Specifications subject to change without notice.

14

440 04 4900 02

Proper instrumentation is required to service electrical controls.

The control in this furnace is equipped with a Status Code LED

(Light

−

Emitting Diode) to aid in installation, servicing, and

troubleshooting. Status codes can be viewed at the indicator in

blower door. The green furnace control LED is either ON

heartbeat, off or a code composed of 1 or 2 digits. The first digit

is the number of short flashes, the second digit is the number of

long flashes.

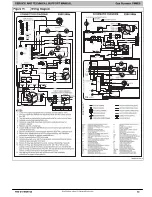

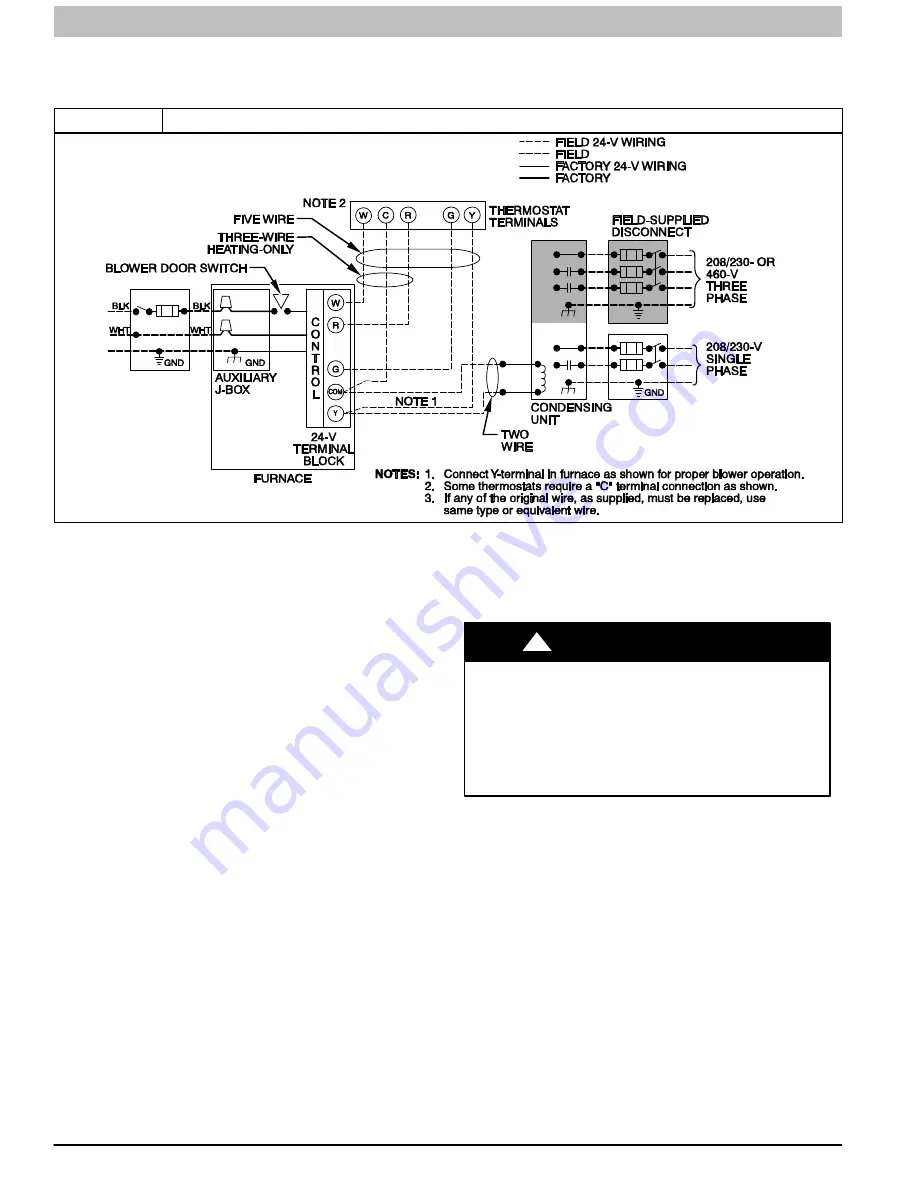

Figure 7

Heating and Cooling Application Wiring Diagram

−

Single

−

Stage Thermostat

L12F048

220

−

V FIELD

SUPPLIED

DISCONNECT

220

−

V WIRING

220

−

, 208/230

−

, 460

−

V WIRING

For an explanation of status codes, refer to service label

located on blower door or

, and the troubleshooting

guide which can be obtained from your distributor.

Retrieving Stored Fault Codes

NOTE

: Fault codes cannot be retrieved if a thermostat signal

(24-V on W, Y, G, etc.) is present, or if any delays such as

blower off-delays are active.

The stored status codes will NOT be erased from the control

memory when 220- or 24-V power is interrupted. See the

Service Label (See

) for more information. The most

recent fault code may be retrieved as follows:

1. Leave 220

−

V power connected to furnace.

2. Observe the status LED through the blower door (the

lower door on upflow applications) indicator. Refer to the

) to interpret the LED.

3. Remove the Main/Control door (the upper door on upflow

installations).

4. BRIEFLY disconnect and reconnect ONE of the main

limit wires.

5. The LED will flash the last stored fault code. Refer to the

) to interpret the LED.

6. A component test sequence will follow.

7. Reinstall the Main/Control door.

Component Self

−

Test

NOTE

: The furnace control component test allows all

components to run for a short time; except the gas valve and

humidifier terminal HUM 24 VAC are not energized. The EAC

terminal is energized when the blower is energized. The HUM

terminal is energized when the inducer is energized. This

feature helps diagnose a system problem in case of a

component failure. The component test feature will not operate

if any thermostat signal is present at the control and not until all

time delays are completed.

To begin Component Self

−

Test:

1. Remove blower access door.

2. Disconnect the thermostat R lead from furnace control.

3. Manually close blower door switch.

Caution must be taken when manually closing this switch for

service purposes.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury, or death.

Blower access door switch opens 220

−

V 50Hz power

to control. No component operation can occur unless

switch is closed. Caution must be taken when

manually closing this switch for service purposes.

!

WARNING

4. For approximately 2 sec, short (jumper) the C terminal on

control to the TEST/TWIN 3/16—in. (5 mm)

quick-connect terminal on control until the LED goes off.

Remove jumper from terminals. (See

NOTE

: If TEST/TWIN and C terminals are jumpered longer

than 2 sec, LED will flash code 10 and ignore component test

request.

Component test sequence is as follows:

a. LED will display previous status code 4 times.

b. Inducer motor starts and continues to run until Step f of

component test sequence.

c. After 8 seconds the hot surface igniter is energized for

18 sec., then off.

d. Blower motor operates on HEAT speed for 12 sec.

e. Blower motor operates on COOL speed for 12 sec.

f. Inducer motor stops.

5. Reconnect R lead to furnace control, remove tape from

blower door switch, and re-install blower door.