SERVICE AND TECHNICAL SUPPORT MANUAL

Gas Furnace: (F/G)9MVE

Specifications subject to change without notice.

18

440 04 4800 00

Troubleshooting

Refer to the service label. (See

—Service Label)

The Troubleshooting Guide

−

) can

be a useful tool in isolating furnace operation problems.

Beginning with the word “Start,” answer each question and

follow the appropriate arrow to the next item.

The Guide

−

Flow Chart will help to identify the problem or

failed component. After replacing any component, verify correct

operation sequence.

Proper instrumentation is required to service electrical controls.

The control in this furnace is equipped with a Status Code LED

(Light

−

Emitting Diode) to aid in installation, servicing, and

troubleshooting. Status codes can be viewed at the indicator in

blower door. The amber furnace control LED is either a

heartbeat, off or a code composed of 1 or 2 digits. The first digit

is the number of short flashes, the second digit is the number of

long flashes.

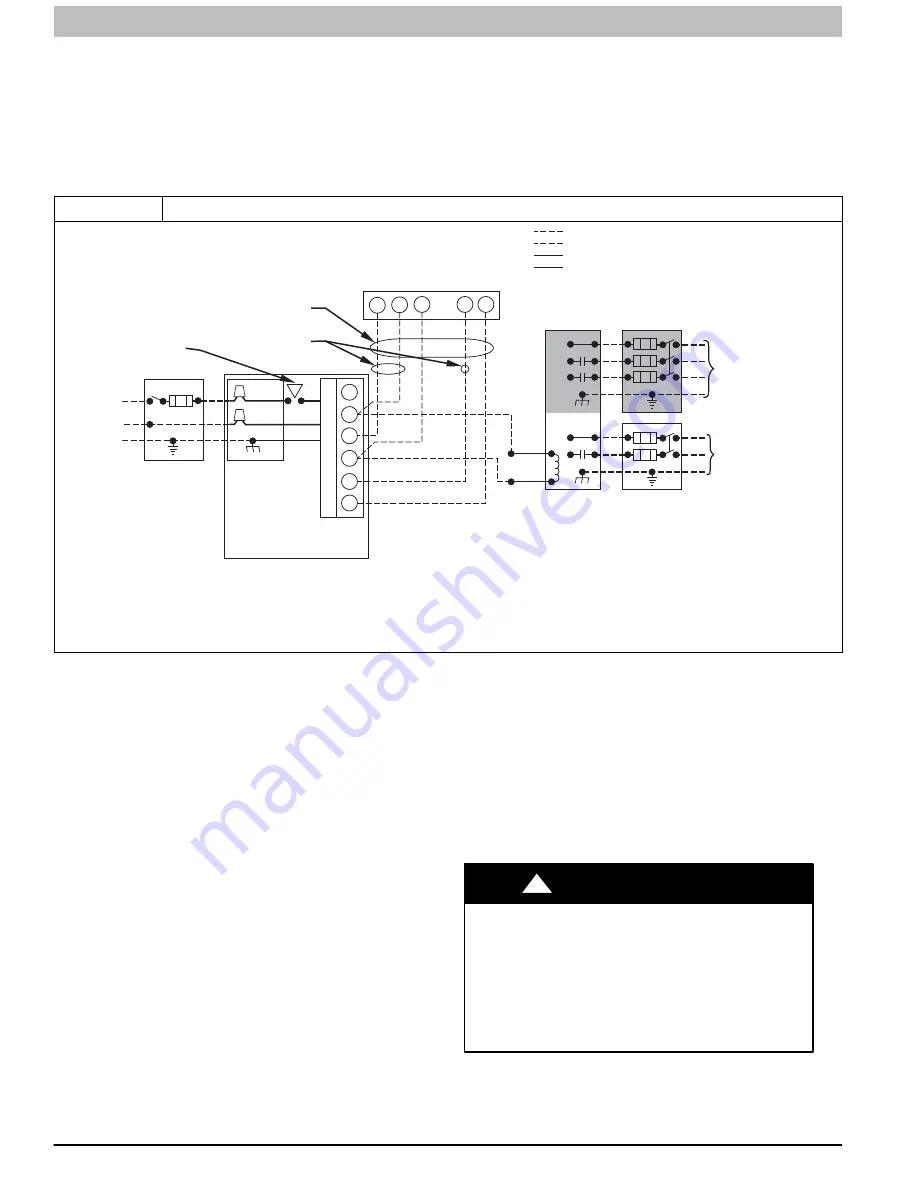

Figure 8

Heating and Cooling Application Wiring Diagram with Single

−

Stage Thermostat

A11401

115-VOLT FIELD-

SUPPLIED

FUSED

DISCONNECT

JUNCTION

BOX

24-VOLT

TERMINAL

BLOCK

THREE-WIRE

HEATING-

ONLY

FIVE

WIRE

NOTE 2

NOTE 1

1-STAGE

THERMOSTAT

TERMINALS

FIELD-SUPPLIED

FUSED DISCONNECT

CONDENSING

UNIT

FURNACE

COM

R

W

C

Y

R

G

GND

GND

FIELD 24-VOLT WIRING

FIELD 115-, 208/230-, 460-VOLT WIRING

FACTORY 24-VOLT WIRING

FACTORY 115-VOLT WIRING

Connect Y/Y2-terminal as shown for proper operation.

Some thermostats require a "C" terminal connection as shown.

If any of the original wire, as supplied, must be replaced, use

same type or equivalent wire.

208/230- OR

460-VOLT

THREE

PHASE

208/230-

VOLT

SINGLE

PHASE

WHT

BLK

WHT

BLK

W/W1

W2

Y/Y2

G

NOTES:

1.

2.

3.

BLOWER

DOOR

SWITCH

C

O

N

T

R

O

L

For an explanation of status codes, refer to service label

located on control door or

guide which can be obtained from your distributor.

Retrieving Stored Fault Codes

The stored status codes will NOT be erased from the control

memory, when 115

−

or 24

−

v power is interrupted. The control

will store up to the last 7 Status Codes in order of occurrence.

1. To retrieve status codes, proceed with the following:

NOTE

: NO thermostat signal may be present at control, and all

blower

−

OFF delays must be completed.

a. Leave 115

−

v power to furnace turned on.

b. Look into blower door indicator for current LED

status.

c. Remove blower door.

NOTE

: The Status Codes cannot be retrieved by

disconnecting the limit switch. To retrieve Status Codes, follow

the procedure below.

2. Turn Setup Switch, SW1

−

1 “ON.”

3. Manually close blower door switch.

4. Control will flash up to 7 Status Codes.

5. The last Status Code, or 8th Code, will be a heartbeat.

6. Turn SW1

−

1 “OFF.”

7. A heartbeat amber LED will appear and indicates proper

operation.

8. Release blower door switch, install control door and

refer to the SERVICE label on the control door for more

information.

Component Self

−

Test

Component Test can ONLY be initiated by performing the

following:

1. Remove blower door.

2. Remove the wire from the “R” terminal of the control

board.

3. Turn Setup Switch, SW

−

1

−

6 “ON.”

4. Manually close blower door switch.

Blower door switch opens 115

−

v power to control. No

component operation can occur unless switch is closed.

Caution must be taken when manually closing this switch for

service purposes.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury, or death.

Blower door switch opens 115

−

v power to furnace

control. No component operation can occur unless

switch is closed. Exercise caution to avoid electrical

shock from exposed electrical components when

manually closing this switch for service purposes.

!

WARNING

5. Component Test sequence will function as follows:

a. Inducer motor starts on high

−

speed and continues to

run until Step (d.) of component test sequence.