4

440 01 4201 03

Specifications subject to change without notice.

(914 mm) horizontally from the furnace. See NFPA 90B

or local code for further requirements.

Table 1

Minimum Clearances to

Combustible Materials for All Units

POSITION

CLEARANCE

In(mm)

REAR

0

FRONT (Combustion air openings in fur-

nace and in structure)

1 (25)

Required for service

*24 (610)

All Sides of Supply Plenum

*1 (25)

Sides

0

Vent

0

Top of Furnace

1 (25)

* Consult your local building codes.

13. These furnaces SHALL NOT be installed directly on

carpeting, combustible tile, or any other combustible

material other than wood flooring. In downflow

installations, factory accessory floor base MUST be

used when installed on combustible materials and wood

flooring. Special base is not required when this furnace

is installed on manufacturer’s Coil Assembly is used.

See

for clearance to combustible construction

information.

Introduction

The 4

−

way multipoise Category IV condensing furnace is CSA

design

−

certified as a direct

−

vent (2

−

pipe) and ventilated

combustion air venting installations. (See

) The

furnace is factory

−

shipped for use with natural gas. The

furnace can be converted in the field for use with propane gas

when a factory

−

supplied conversion kit is used. Refer to the

furnace rating plate for conversion kit information.

This furnace is not approved for installation in mobile homes,

recreational vehicles, or outdoors.

This furnace is designed for minimum continuous return

−

air

temperature of 60

°

F (15

°

C) db or intermittent operation down to

55

°

F (15

°

C) db such as when used with a night setback

thermostat. Return

−

air temperature must not exceed 80

°

F

(27

°

C) db. Failure to follow these return

−

air temperature limits

may affect reliability of heat exchangers, motors, and controls

The furnace should be sized to provide 100 percent of the

design heating load requirement plus any margin that occurs

because of furnace model size capacity increments. Heating

load estimates can be made using approved methods available

from Air Conditioning Contractors of America (Manual J);

American Society of Heating, Refrigerating, and

Air

−

Conditioning Engineers; or other approved engineering

methods. Excessive oversizing of the furnace could cause the

furnace and/or vent to fail prematurely.

For accessory installation details, refer to the applicable

instruction literature.

NOTE:

Remove all shipping materials, parts assemblies and

literature before operating the furnace.

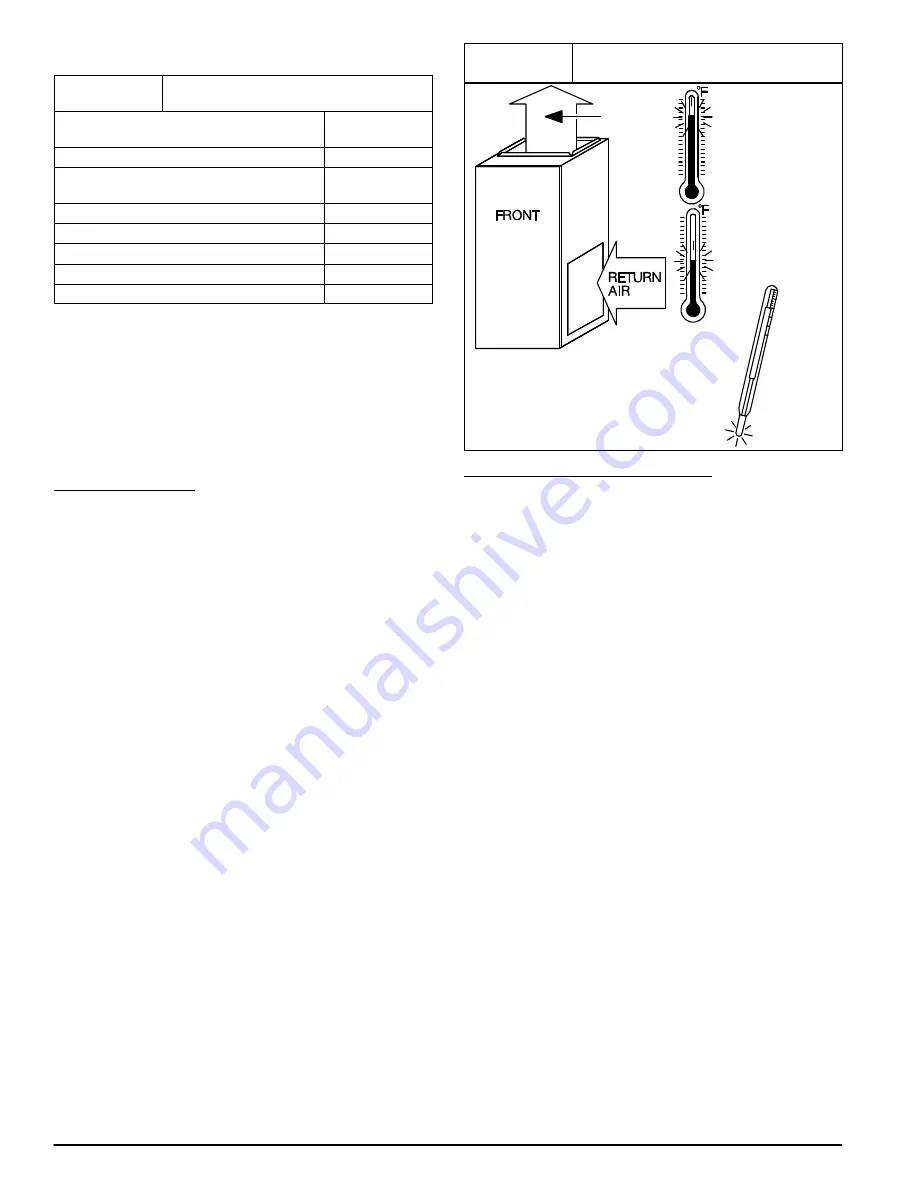

Figure 1

Freeze Protection and Return Air

Temperature

32

°

F/0

°

C MINIMUM INSTALLED

AMBIENT OR FREEZE

PROTECTION REQUIRED

SUPPLY AIR

MAX 80

°

F/27

°

C

MIN 60

°

F/16

°

C

A10490

Codes and Standards

Follow all national and local codes and standards in

addition to these instructions.

The installation must comply

with regulations of the serving gas supplier, local building,

heating, plumbing, and other codes. In absence of local codes,

the installation must comply with the national codes listed

below and all authorities having jurisdiction.

In the United States and Canada, follow all codes and

standards for the following:

Safety

US: National Fuel Gas Code (NFGC) NFPA

54

−

2009/ANSI Z223.1

−

2009 and the Installation

Standards, Warm Air Heating and Air Conditioning

Systems ANSI/NFPA 90B

CANADA: National Standard of Canada, Natural Gas

and Propane Installation Code (NSCNGPIC)

CAN/CSA B149.1

−

2010

General Installation

US: NFGC and the NFPA 90B. For copies, contact the

National Fire Protection Association Inc.,

Batterymarch Park, Quincy, MA 02269; or for only the

NFGC contact the American Gas Association, 400 N.

Capitol, N.W., Washington DC 20001.

CANADA: NSCNGPIC. For a copy, contact Standard

Sales, CSA International, 178 Rexdale Boulevard,

Etobicoke (Toronto), Ontario, M9W 1R3, Canada.

Combustion and Ventilation Air

US: Section 9.3 of the NFPA54/ANSI Z223.1

−

2009,

Air for Combustion and Ventilation

CANADA: Part 8 of the CAN/CSA B149.1

−

2010,

Venting Systems and Air Supply for Appliances