GWA

Gas-Fired Water Boilers –

Boiler Manual

3

Part Number 670 01 1001 00

Service clearances

1. Provide minimum clearances for cleaning and servicing the

boiler and for access to controls and components as listed in

the table below:

2. Provide at least screwdriver clearance to jacket front panel

screws for removal of front panel for inspection and minor

service. If unable to provide at least screwdriver clearance,

install unions and shutoff valves in system so boiler can be

moved for servicing.

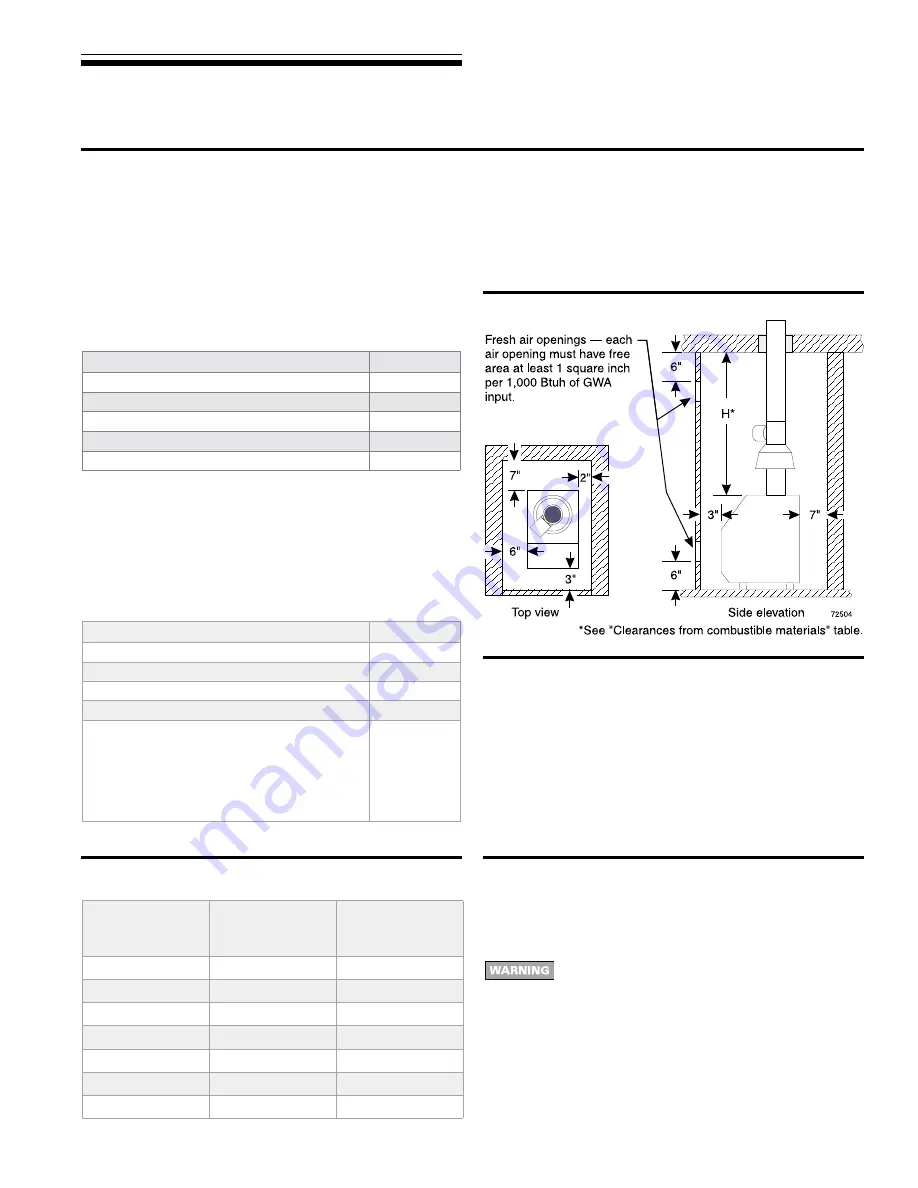

Figure 1

Minimum clearances

Clearances

Service clearances:

Minimum

Top

(for cleaning flueways)

35"

Front

(for access to controls and components)

18"

Back

7"

Left side

(for cleaning and servicing)

24"

Right side

7"

Flooring and foundation

Flooring

The GWA boiler is approved for installation on combustible flooring,

but must never be installed on carpeting.

Do not install boiler on carpeting even if foundation is

used. Fire can result, causing severe personal injury,

death or substantial property damage.

Foundation

1.

Provide a solid brick or minimum 2-inch thick concrete

foundation pad if any of the following is true:

•

floor can become flooded.

•

the boiler mounting area is not level.

2. See Table 1 for minimum foundation dimensions.

Residential garage installation

Take the following special precautions when installing the boiler in

a residential garage. If the boiler is located in a residential garage,

per ANSI Z223.1, paragraph 5.1.9:

•

Mount the boiler a minimum of 18 inches above the floor of the

garage to assure the burner and ignition devices will be no less

than 18 inches above the floor.

•

Locate or protect the boiler so it cannot be damaged by a moving

vehicle.

Minimum clearance to combustible materials

1. Hot water pipes must be at least ½" from combustible material.

2. Single-wall vent pipe must be at least 6 inches from combustible

material.

3. Type B double-wall metal vent pipe — See vent manufacturer’s

recommendation for clearances to combustible material.

Small space installations

1. When the boiler is located in a closet or small space, provide

clearances no less than those shown in Figure 1. The clearances

are required to any surface, whether combustible or non-

combustible.

Table 1

Minimum foundation size

1

Prepare boiler location

continued

Clearances from combustible materials:

Minimum

Front

(provide means of access)

3"

Back

7"

Left side

(provide means of access)

6"

Right side

2"

Top

GWA052 to GWA105

GWA140

GWA175

GWA210

GWA245

H

35"

35½"

38½"

39¾"

42½"

Boiler

model

Minimum

foundation

length

Minimum

foundation

width

GWA052

25"

12"

GWA070

25"

12"

GWA105

25"

15"

GWA140

25"

18"

GWA175

25"

21"

GWA210

25"

24"

GWA245

25"

27"

GWA

Gas-Fired Water Boilers –

Boiler Manual

34

Part Number 670 01 1001 00

Figure 21

Dimensional drawing — ALL DIMENSIONS IN INCHES

13 Dimensions

Boiler

model

number

Supply

tapping

(inches NPT)

Return

tapping

(inches NPT)

Gas connection

& manifold size

(Note 3)

(inches NPT)

“A”

Vent

location

(inches)

“D”

Vent

diameter

(inches)

“W”

Jacket

width

(inches)

“H”

Damper

height

(inches)

GWA052

1

1

/

4

1

1

/

4

1

/

2

5

4

10

45

3

/

8

GWA070

1

1

/

4

1

1

/

4

1

/

2

5

4

10

52

3

/

8

GWA105

1

1

/

4

1

1

/

4

1

/

2

6

1

/

2

5

13

54

3

/

8

GWA140

1

1

/

4

1

1

/

4

1

/

2

8

6

16

57

7

/

8

GWA175

1

1

/

4

1

1

/

4

1

/

2

9

1

/

2

6

19

60

7

/

8

GWA210

1

1

/

4

1

1

/

4

3

/

4

11

7

22

62

1

/

8

GWA245

1

1

/

4

1

1

/

4

3

/

4

12

1

/

2

7

25

64

7

/

8

Note 3:

Size gas piping from meter to boiler per local utility requirements.