Maintenance, troubleshooting, spare parts and dismantling

iDRY iRDP CT 20-500

33

Prior to carrying out maintenance works at the dryer, switch it off and wait for at least 30 minutes.

Caution!

Hot surfaces!

During operation, several components can reach surface temperatures of more than 140°F (60°C).

There is the risk of burns.

All components concerned are installed inside of the closed housing. The housing must only be opened

by certified skilled personnel.

Some components can reach high temperatures during operation. Avoid any contact until the system or

the component has cooled down.

FAULT POSSIBLE

REASON

– SUGGESTED MEASURE

The display of DMC51

is not lit

Verify that the system is powered.

Verify the electric wiring.

If installed – HPS pressure switch has been activated – see specific point

iRDP CT 200-500 3phase - Blow of fuse (FU2 on the electric diagram) of the auxiliary

circuit - replace it and check the proper operation of the dryer.

iRDP CT 200-500 3phase – The remote control is OFF (see contact on terminals 1-2

on electric diagram)

The compressor does

not work.

If ESS=YES (see section 8.12.7) – the Dew Point displayed on DMC51 is sufficiently

low, the led

is OFF, so the compressor is not active – wait that the temperature

becomes higher.

Activation of the compressor internal thermal protection – wait 30 minutes and then

retry.

Verify the electric wiring.

If installed – the KC relay is faulty – replace it

If installed – replace the internal thermal protection and/or the start-up relay and/or

the start-up capacitor and/or the working capacitor.

DMC51 – The led

is ON – see specific point.

If the compressor still does not work, replace it.

If ESS=YES (see

section 8.12.7) - The

compressor remains

OFF unexpected short

time.

The OFF time of the compressor is related to the actual dryer thermal load. If dryer is

running in low or no-load conditions and at mild/low ambient temperatures, and the

compressor remains OFF for too short time (less than 3-5 minutes), check which of the

following reasons is creating the malfunction:

1. The DewPoint probe T1 doesn’t correctly detect the temperature - ensure the sensor

is pushed into the bottom of probe well.

2. The thermal insulation of DewPoint probe T1 is damaged – restore the thermal

insulation

3. The ambient temperature is too high or the room aeration is insufficient - provide

proper ventilation.

4. The solenoid valve EVL is not operating correctly - see specific point.

5. If installed - The check valve CHV is jammed (open) - contact a ICP service

technician to replace it.

The fan of the

condenser does not

work

Verify the electric wiring.

PV pressure switch is faulty. Contact a ICP service technician.

iRDP CT 200-500 3phase- Blow of fuse (FU1-FU2 on the electric diagram) - replace it

and check the proper operation of the dryer.

There is a leak in the refrigerant circuit – contact a ICP service technician.

If the fan still does not work, replace it.

Summary of Contents for iDRY iRDP CT 100

Page 29: ...Technical data iDRY iRDP CT 20 500 29 11 2 Technical data iDRY iRDP CT 20 500 2 1 230 60...

Page 38: ...Maintenance troubleshooting spare parts and dismantling 38 iDRY iRDP CT 20 500...

Page 39: ...Maintenance troubleshooting spare parts and dismantling iDRY iRDP CT 20 500 39...

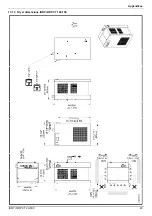

Page 42: ...Appendices 42 iDRY iRDP CT 20 500 13 1 2 Dryer dimensions iDRY iRDP CT 75...

Page 43: ...Appendices iDRY iRDP CT 20 500 43 13 1 3 Dryer dimensions iDRY iRDP CT 100 150...

Page 44: ...Appendices 44 iDRY iRDP CT 20 500 13 1 4 Dryer dimensions iDRY iRDP CT 200 250...

Page 45: ...Appendices iDRY iRDP CT 20 500 45 13 1 5 Dryer dimensions iDRY iRDP CT 300 350...

Page 46: ...Appendices 46 iDRY iRDP CT 20 500 13 1 6 Dryer dimensions iDRY iRDP CT 400 500...

Page 47: ...Appendices iDRY iRDP CT 20 500 47 13 1 7 Dryer dimensions iDRY iRDP CT 200 250 3phase...

Page 48: ...Appendices 48 iDRY iRDP CT 20 500 13 1 8 Dryer dimensions iDRY iRDP CT 300 350 3phase...

Page 49: ...Appendices iDRY iRDP CT 20 500 49 13 1 9 Dryer dimensions iDRY iRDP CT 400 500 3phase...

Page 51: ...Appendices iDRY iRDP CT 20 500 51 13 2 2 Exploded diagram iDRY iRDP CT 20 30...

Page 52: ...Appendices 52 iDRY iRDP CT 20 500 13 2 3 Exploded diagram iDRY iRDP CT 50...

Page 53: ...Appendices iDRY iRDP CT 20 500 53 13 2 4 Exploded diagram iDRY iRDP CT 75...

Page 54: ...Appendices 54 iDRY iRDP CT 20 500 13 2 5 Exploded diagram iDRY iRDP CT 100...

Page 55: ...Appendices iDRY iRDP CT 20 500 55 13 2 6 Exploded diagram iDRY iRDP CT 125 150...

Page 56: ...Appendices 56 iDRY iRDP CT 20 500 13 2 7 Exploded diagram iDRY iRDP CT 200 250...

Page 57: ...Appendices iDRY iRDP CT 20 500 57 13 2 8 Exploded diagram iDRY iRDP CT 300 350...

Page 58: ...Appendices 58 iDRY iRDP CT 20 500 13 2 9 Exploded diagram iDRY iRDP CT 400 500...

Page 59: ...Appendices iDRY iRDP CT 20 500 59 13 2 10 Exploded diagram iDRY iRDP CT 200 250 3phase...

Page 60: ...Appendices 60 iDRY iRDP CT 20 500 13 2 11 Exploded diagram iDRY iRDP CT 300 350 3phase...

Page 61: ...Appendices iDRY iRDP CT 20 500 61 13 2 12 Exploded diagram iDRY iRDP CT 400 500 3phase...