Maintenance, troubleshooting, spare parts and dismantling

36

iDRY iRDP CT 20-500

The

alarm

(toC),

- ON/OFF cycles of the

compressor too

frequent –

has been triggered

If ESS=YES (see section 8.12.7) - The refrigerating compressor must remain ON for

a minimum time (approx. 6 minutes) within which, if necessary, DMC51 will activate

the solenoid EVH that enables the operation of the hot gas by-pass valve. To avoid

freezing, if the DewPoint drops too low in despite the hot gas by-pass valve is in

operation, the compressor is switched OFF before its minimum ON time (approx. 6

minutes). If this happens too many times the alarm

(TOC) is activated to avoid

damaging the compressor.

Check which of the following reasons has caused the alarm:

1. The inlet air is too cold – restore the nominal conditions.

2. The ambient temperature is too low - restore the nominal conditions.

3. The hot gas bypass valve is out of setting – contact a ICP service technician to

restore nominal setting.

4. The solenoid valve EVH is not operating correctly - see specific point.

The

alarm

(ICE)

has been triggered

Check which of the following reasons has caused the alarm:

1. The inlet air is too cold – restore the nominal conditions.

2. The ambient temperature is too low - restore the nominal conditions.

3. The refrigerating compressor is always ON, even though the led

is OFF – verify

the electric wiring or KC relay (if installed) is faulty – replace it.

DMC51 - The LED

is ON or flashing

With

LED flashing: one or more alarms are active and the display shows

and the active alarms.

With

LED lit: one or more alarms are waiting to be reset and the display shows

and the alarms that are no longer active but not yet reset.

The alarms are displayed by the following messages:

1.

: LP - LPS pressure switch activated (low pressure) – see specific paragraph.

2.

: Hdt - Compressor discharge temperature too high (probe T2) – see specific

paragraph.

3.

: ICE - Temperature inside the exchanger too low (probe T1) – the dew point is

too low – see specific paragraph.

4.

: toC – ON/OFF cycles of the compressor too frequent – Compressor has been

repeatedly switched OFF before its minimum ON time (approx. 6 minutes) - see

specific paragraph.

5.

: PF1 - Failure temperature probe T1 (DewPoint) – verify electric wiring and/or

replace probe.

6.

: PF2 – Failure temperature probe T2 (compressor outlet) – If probe T2 installed :

verify electric wiring and/or replace probe; If probe T2 not installed : verify electric

wiring and/or replace the resistor R.

NOTE: after solving the problem, the alarms must be reset (simultaneously press

the

Set

+

buttons for three seconds).

DMC51 - The LED

is ON or flashing

With

LED flashing, one or more service warnings are active.

With

LED lit: one or more service warnings are waiting to be reset. The display

shows the dew point temperature and the active or not reset service warning.

The service warnings are displayed by the following messages:

1.

: Hdp - Dew point too high (higher than the set HdS value) – see specific

paragraph.

2.

: Ldp - Dew point too low – see specific paragraph.

3.

: SrV - Service - maintenance notification time expired (parameter SrV) – carry

out the scheduled maintenance and reset the hour meter.

NOTE: after solving the problem, the service warnings must be reset

(simultaneously press the

Set

+

buttons for three seconds)

.

Summary of Contents for iDRY iRDP CT 100

Page 29: ...Technical data iDRY iRDP CT 20 500 29 11 2 Technical data iDRY iRDP CT 20 500 2 1 230 60...

Page 38: ...Maintenance troubleshooting spare parts and dismantling 38 iDRY iRDP CT 20 500...

Page 39: ...Maintenance troubleshooting spare parts and dismantling iDRY iRDP CT 20 500 39...

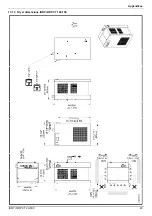

Page 42: ...Appendices 42 iDRY iRDP CT 20 500 13 1 2 Dryer dimensions iDRY iRDP CT 75...

Page 43: ...Appendices iDRY iRDP CT 20 500 43 13 1 3 Dryer dimensions iDRY iRDP CT 100 150...

Page 44: ...Appendices 44 iDRY iRDP CT 20 500 13 1 4 Dryer dimensions iDRY iRDP CT 200 250...

Page 45: ...Appendices iDRY iRDP CT 20 500 45 13 1 5 Dryer dimensions iDRY iRDP CT 300 350...

Page 46: ...Appendices 46 iDRY iRDP CT 20 500 13 1 6 Dryer dimensions iDRY iRDP CT 400 500...

Page 47: ...Appendices iDRY iRDP CT 20 500 47 13 1 7 Dryer dimensions iDRY iRDP CT 200 250 3phase...

Page 48: ...Appendices 48 iDRY iRDP CT 20 500 13 1 8 Dryer dimensions iDRY iRDP CT 300 350 3phase...

Page 49: ...Appendices iDRY iRDP CT 20 500 49 13 1 9 Dryer dimensions iDRY iRDP CT 400 500 3phase...

Page 51: ...Appendices iDRY iRDP CT 20 500 51 13 2 2 Exploded diagram iDRY iRDP CT 20 30...

Page 52: ...Appendices 52 iDRY iRDP CT 20 500 13 2 3 Exploded diagram iDRY iRDP CT 50...

Page 53: ...Appendices iDRY iRDP CT 20 500 53 13 2 4 Exploded diagram iDRY iRDP CT 75...

Page 54: ...Appendices 54 iDRY iRDP CT 20 500 13 2 5 Exploded diagram iDRY iRDP CT 100...

Page 55: ...Appendices iDRY iRDP CT 20 500 55 13 2 6 Exploded diagram iDRY iRDP CT 125 150...

Page 56: ...Appendices 56 iDRY iRDP CT 20 500 13 2 7 Exploded diagram iDRY iRDP CT 200 250...

Page 57: ...Appendices iDRY iRDP CT 20 500 57 13 2 8 Exploded diagram iDRY iRDP CT 300 350...

Page 58: ...Appendices 58 iDRY iRDP CT 20 500 13 2 9 Exploded diagram iDRY iRDP CT 400 500...

Page 59: ...Appendices iDRY iRDP CT 20 500 59 13 2 10 Exploded diagram iDRY iRDP CT 200 250 3phase...

Page 60: ...Appendices 60 iDRY iRDP CT 20 500 13 2 11 Exploded diagram iDRY iRDP CT 300 350 3phase...

Page 61: ...Appendices iDRY iRDP CT 20 500 61 13 2 12 Exploded diagram iDRY iRDP CT 400 500 3phase...