SERVICE AND TECHNICAL SUPPORT MANUAL

Gas Furnace: N9MSB

Specifications subject to change without notice.

16

440 04 4413 00

2. Remove blower door.

3. All factory wires can be left connected, but field

thermostat and accessory wiring may need to be

disconnected depending on their length and routing.

4. If the vent and combustion air pipe passes through the

blower compartment, it will be necessary to remove the

pipes from the blower compartment.

Disconnect the vent and combustion air pipe by:

a. Loosen the clamps on the vent couplings and

combustion air pipe external to the furnace.

b. Separate the pipes from the couplings and move

them aside.

c. Loosen the clamps on the vent couplings and

combustion air pipe located on the blower shelf.

d. Separate the pipes from the blower compartment and

set aside.

e. Remove the couplings from the pipe adapters and set

aside.

f. After servicing the blower, reverse steps a through e.

g. Tighten all clamps 15 lb

−

in.

See

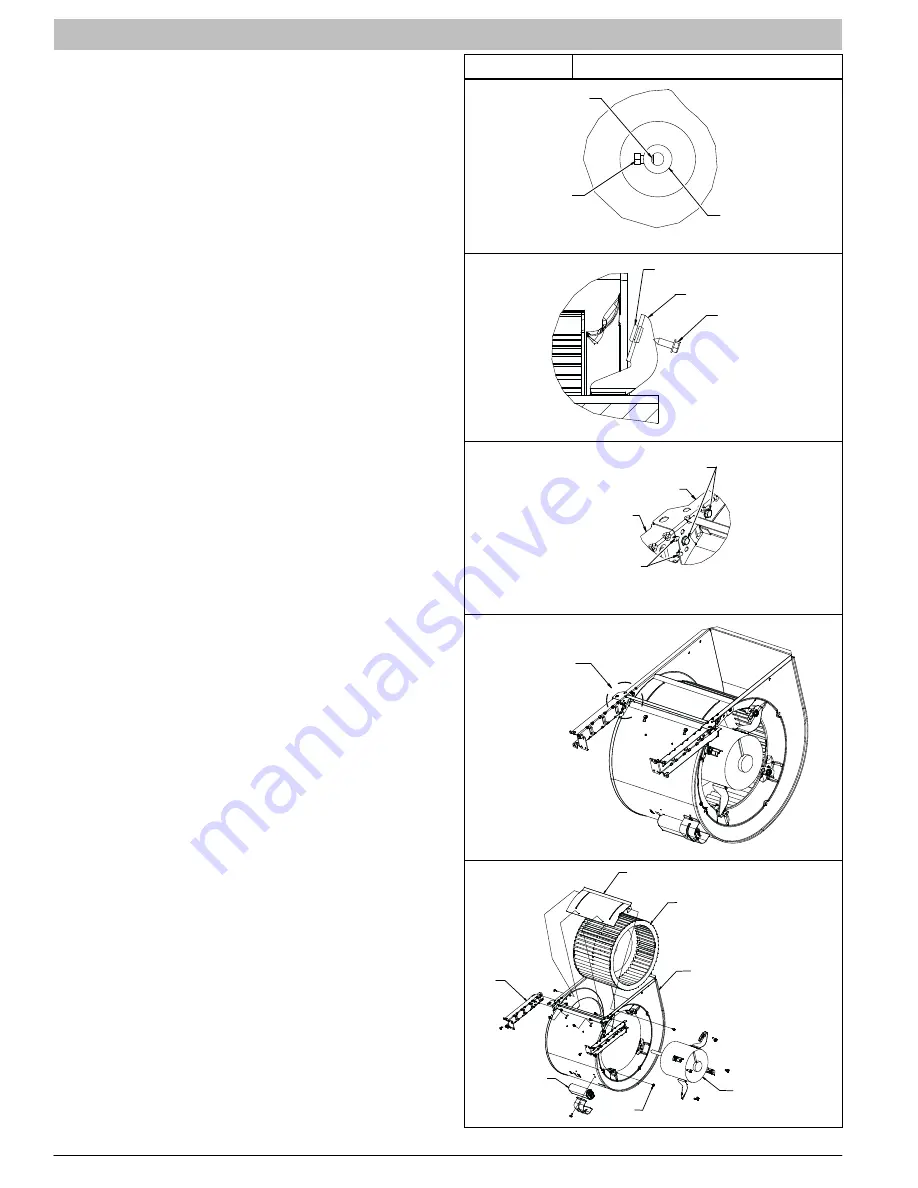

Figure 8

for steps 5 through 14.

5. Remove screws securing blower assembly to blower

shelf and slide blower assembly out of furnace. Detach

ground wire and disconnect blower motor harness plugs

from blower motor.

NOTE

: Blower wheel is fragile. Use care.

6. Clean blower wheel and motor by using a vacuum with

soft brush attachment. Be careful not to disturb balance

weights (clips) on blower wheel vanes. Do not bend

wheel or blades as balance will be affected.

7. If greasy residue is present on blower wheel, remove

wheel from the blower housing and wash it with an

appropriate degreaser. To remove wheel:

a. Mark blower wheel location on shaft before

disassembly to ensure proper reassembly.

b. Loosen setscrew holding blower wheel on motor

shaft.

NOTE

: Mark blower mounting arms and blower housing so

each arm is positioned at the same hole location during

reassembly.

c. Mark blower wheel orientation and cutoff plate

location to ensure proper reassembly.

d. Remove screws securing cutoff plate and remove

cutoff plate from housing.

e. Remove bolts holding motor mounts to blower

housing and slide motor and mounts out of housing.

f. Remove blower wheel from housing.

g. Clean wheel per instructions on degreaser cleaner.

Do not get degreaser in motor.

8. Reassemble motor and blower wheel by reversing items

7b through 7f. Ensure wheel is positioned for proper

rotation.

9. Torque motor mounting bolts to 40 +/

−

10 lb

−

in. when

reassembling.

10. Torque blower wheel set screw to 160 +/

−

20 lb

−

in. when

reassembling.

11. Verify that blower wheel is centered in blower housing

and set screw contacts the flat portion of the motor shaft.

Loosen set screw on blower wheel and reposition if

necessary.

12. Spin the blower wheel by hand to verify that the wheel

does not rub on the housing.

13. Reinstall blower assembly in furnace.

Figure 8

Blower Assembly

A11584A

SET SCREW

MOTOR WHEEL HUB

MOTOR SHAFT FLAT

A11584B

SCREW

MOTOR ARM

GROMMET

A11584C

SCREW LOCATION

BLO HSG ASSY

BRACKET

BRACKET

ENGAGEMENT

DETAIL

A

A11584D

SEE DETAIL

A

POWER CHOKE

BRACKET

SCREW

(GND)

BLOWER HSG ASSY

MOTOR, BLOWER

WHEEL, BLOWER

CUTOFF, BLOWER

A11584E

OR CAPACITOR

WHEN REQUIRED