SERVICE AND TECHNICAL SUPPORT MANUAL

Gas Furnace: N9MSE

Specifications subject to change without notice.

6

440 04 4401 03

5. Turn gas supply manual shutoff valve to ON position.

6. Turn furnace gas valve switch to ON position.

7. Jumper R and W thermostat connections at the furnace

control board.

8. When main burners ignite, confirm inlet gas pressure is

between 4.5 in. w.c. (1125 Pa) and 13.6 in. w.c. (3388

Pa).

9. Remove jumper across thermostat connections to

terminate call for heat. Wait until the blower off delay is

completed.

10. Turn furnace gas valve electric switch to OFF position.

11. Turn gas supply manual shutoff valve to OFF position.

12. Turn off furnace power supply.

13. Remove manometer from the inlet pressure tap of the

gas valve.

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Re

−

install manifold pressure tap plug in gas valve to

prevent gas leak.

!

WARNING

14. Apply pipe dope sparingly to end of inlet gas pipe plug

and re

−

install in the gas valve.

Adjust Manifold Pressure

1. Adjust manifold pressure to obtain proper gas input rate.

(See

Figure 3

)

a. Turn gas valve ON/OFF switch to OFF.

b. Remove manifold pressure tap plug from gas valve.

c. Connect a water column manometer or similar device

to manifold pressure tap.

d. Turn gas valve ON/OFF switch to ON.

e. Manually close blower door switch.

f. Jumper R and W thermostat connections on control

to start furnace. (See

Figure 4

)

g. Remove regulator adjustment cap from gas valve

pressure regulator (See

Figure 3

) and turn adjusting

screw (3/16 or smaller flat

−

tipped screwdriver)

counterclockwise (out) to decrease input rate or

clockwise (in) to increase input rate.

NOTICE

DO NOT set low

−

heat manifold pressure less than 2.8

−

in. w.c.

(697 Pa) or more than 3.8

−

in. w.c. (947 Pa) for natural gas. If

required manifold pressure is outside this range, change main

burner orifices.

h. When correct input is obtained, replace cap that

conceal gas valve regulator adjustment screw. Main

burner flame should be clear blue, almost transparent

(See

Figure 13

)

i. Remove jumper R to W.

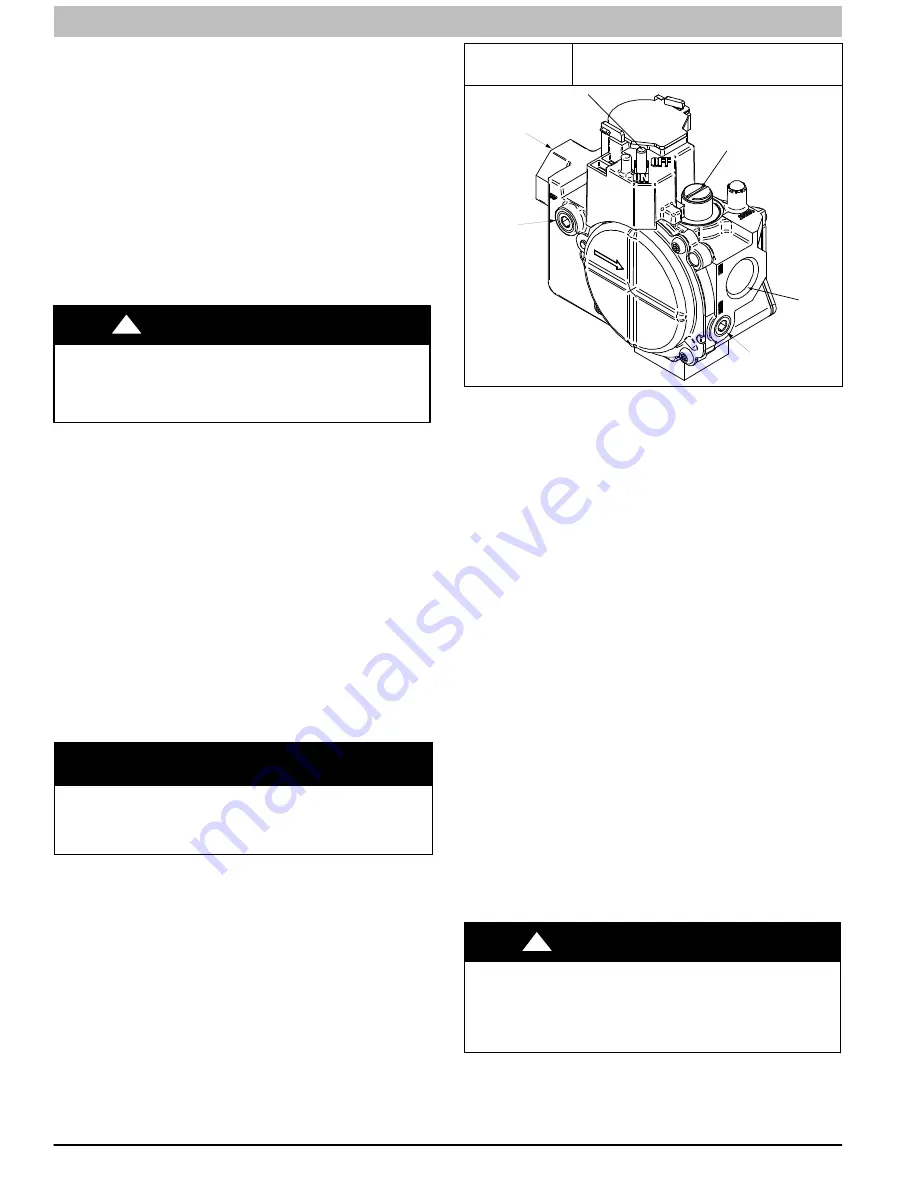

Figure 3

Redundant Automatic Gas Valve

(Single Stage)

ON/OFF Switch

Regulator Seal Cap

Regulator Adjustment

Regulator Seal Cap under Cap

1/2” NPT Outlet

1/8” NPT Manifold

Pressure Tap

1/8” NPT Inlet

Pressure Tap

1/2” NPT Inlet

A11153

2. Verify natural gas input rate by clocking meter.

NOTE

: Contact your HVAC distributor or gas supplier for metric

gas meter Tables, if required.

a. Turn off all other gas appliances and pilots served by

the meter.

b. Jumper R to W.

c. Run furnace for 3 minutes.

d. Measure time (in sec) for gas meter to complete 1

revolution and note reading. The 2 or 5 cubic feet dial

provides a more accurate measurement of gas flow.

e. Refer to

Table 2

for cubic ft. of gas per hr.

f. Multiply gas rate cu ft./hr by heating value (Btuh/cu

ft.) to obtain input. If clocked rate does not match

required input from Step 1, increase manifold

pressure to increase input or decrease manifold

pressure to decrease input. Repeat steps b through e

until correct input is achieved. Re

−

install regulator

seal cap on gas valve.

g. If clocked rate does not match required input from

Step 1, increase manifold pressure to increase input

or decrease manifold pressure to decrease input.

Repeat steps b through e of Step 1 until correct heat

input is achieved. Re--install regulator seal cap on

gas valve.

3.

Restore furnace to normal operating condition.

a. Turn gas valve ON/OFF switch to OFF.

b. Remove water column manometer or similar device

from manifold pressure tap.

c. Replace manifold pressure tap plug to gas valve.

d. Turn gas valve ON/OFF switch to ON.

e. Check for gas leaks and verify furnace operation

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Reinstall manifold pressure tap plug in gas valve to prevent

gas leak.

!

WARNING