SERVICE AND TECHNICAL SUPPORT MANUAL

Gas Furnace: N9MSE

Specifications subject to change without notice.

20

440 04 4402 03

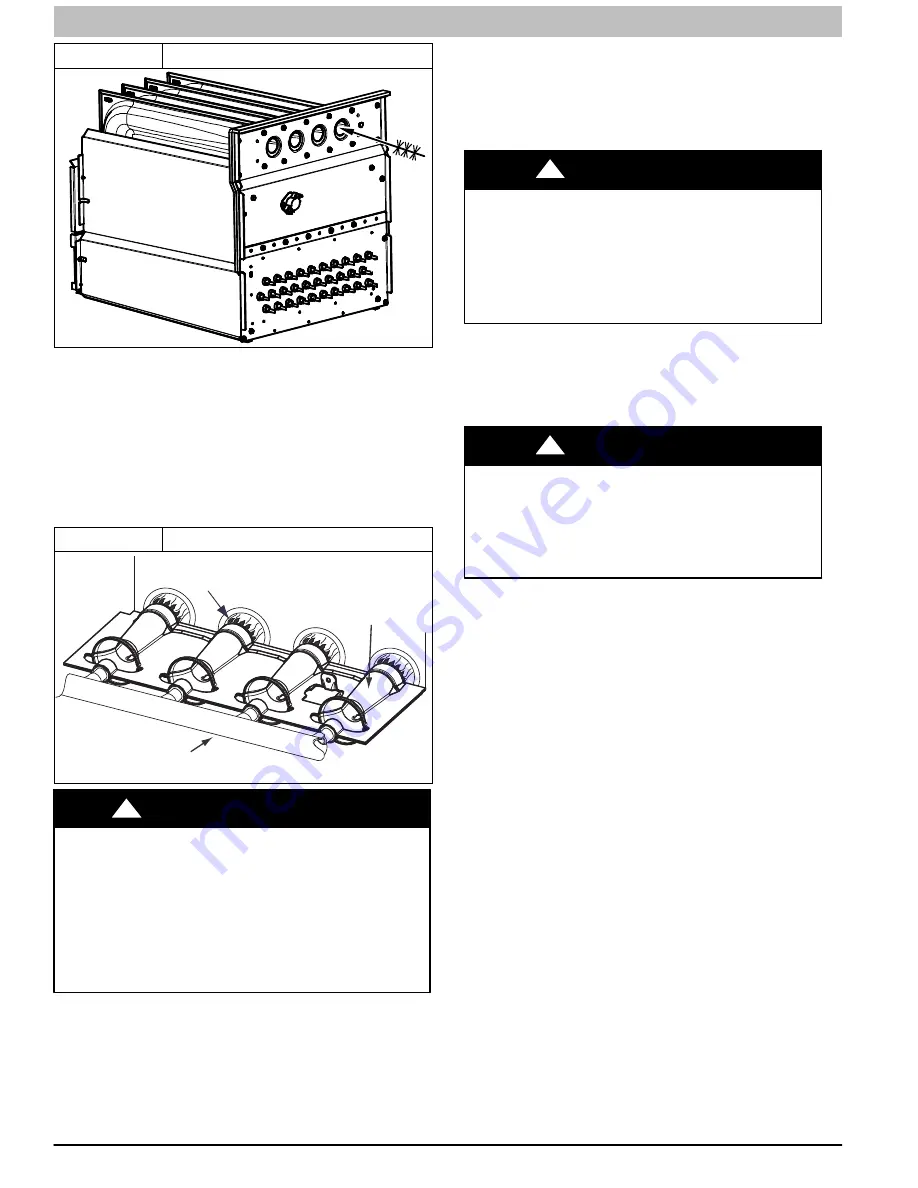

Figure 12

Cleaning Heat Exchanger Cell

A11273

NOTE

: After cleaning, inspect the heat exchangers to ensure

they are free of all foreign objects that may restrict flow of

combustion products.

8. Reverse items 6 through 1 for reassembly.

9. Refer to furnace wiring diagram and reconnect wires to

flame rollout switch, gas valve, igniter, and flame sensor.

10. Turn on gas and electrical supplies to furnace.

11. Check furnace operation through two complete heat

operating cycles. Look at burners. Burner flames should

be clear blue, almost transparent. (See

)

Figure 13

Burner Flame

A11461

Burner Flame

Burner

Manifold

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Never purge a gas line into a combustion chamber. Never

test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection

of leaks to check all connections. A fire or explosion may

result causing property damage, personal injury or loss of

life.

!

WARNING

12. Check for gas leaks.

13. Replace main furnace door.

Secondary Heat Exchangers

The condensing side (inside) of the secondary heat exchanger

CANNOT be serviced or inspected without complete removal of

the heat exchanger assembly. Detailed information on heat

exchanger removal can be obtained from your Distributor.

Winterization

UNIT AND PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in unit

component or property damage.

If the furnace is installed in an unconditioned space

where the ambient temperatures may be 32

_

F (0

_

C) or

lower, freeze protection measures must be taken to

prevent property or product damage.

CAUTION

!

Since the furnace uses a condensing heat exchanger, some

water will accumulate in the unit as a result of the heat transfer

process. Therefore, once it has been operated, it cannot be

turned off and left off for an extended period of time when

temperatures will reach 32

_

F (0

_

C) or lower unless winterized.

Follow these procedures to winterize your furnace:

UNIT COMPONENT DAMAGE HAZARD

Failure to follow this caution may result in damage to the

furnace and other property damage.

Do not use ethylene glycol (automotive antifreeze

coolant or equivalent). Failure of plastic components

may occur.

CAUTION

!

1. Obtain propylene glycol (RV/swimming pool antifreeze or

equivalent).

2. Turn off gas and electrical supplies to your furnace.

3. Remove furnace control door.

4. Remove the top unused rubber plug from the port on the

collector box opposite the condensate trap. (See

)

5. Connect a field supplied 3/8

−

in. (9.5

−

mm) ID tube to the

open port on the collector box

6. Insert a field supplied funnel into the tube.

7. Pour 1 quart of anti

−

freeze solution into the funnel/tube.

Antifreeze should run through the collector box, overfill

condensate trap and flow to an open drain.

8. Replace the rubber plug in the port on the collector box.

9. Remove the middle unused rubber plug from the port on

the collector box opposite the condensate trap. See

)

10. Repeat Steps 5 through 8.

11. If a condensate pump is used, check with pump

manufacturer to verify pump is safe for use with

antifreeze used. Allow pump to start and pump

anti

−

freeze to open drain.

12. Replace main door.

13. When furnace is re

−

started, flush condensate pump with

clear water to check for proper operation before

re

−

starting furnace.

14. Propylene glycol need not be removed before re

−

starting

furnace.