2

443 06 2403 01

Specifications subject to change without notice.

INTRODUCTION

IMPORTANT

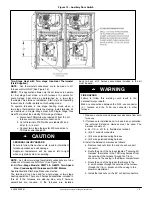

: Only the furnace sizes listed in Table 2 can be

twinned. Both furnaces must have the same product number,

including heating and cooling sizes, to achieve correct

operation.

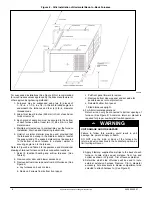

This furnace twinning kit permits connection to the following

furnaces to operate as a single unit on the same duct work:

S

Two multipoise, 33.3 inch (846 mm), single

−

speed,

non

−

condensing furnaces (See Figure 1, Figure 2 and

S

Two multipoise, 33.3 inch (846 mm), two

−

stage,

non

−

condensing furnaces (See Figure 1, Figure 14, and

UNIT AND PROPERTY DAMAGE HAZARD

Failure to follow this warning could result in unit and

property damage.

A non

−

condensing furnace shall NOT be twinned with a

condensing furnace. Two

−

stage condensing or

non

−

condensing furnaces shall not be twinned with any

single stage furnace. Do not twin furnaces that have a

different number of blower motor speed taps together.

Furnaces shall only be twinned in the positions shown.

Variable

−

speed furnaces shall not be twinned.

!

WARNING

DESCRIPTION AND USAGE

Refer to the appropriate section for your furnaces.

SECTION I

: Models N8MSN & N8MSL Multipoise

Single

−

Speed Non

−

Condensing HSI Furnaces

S

Single

−

Stage Heat with Single

−

Stage Gas

−

Heat Thermostat

S

Two

−

Stage Heat with Two

−

stage Gas

−

Heat Thermostat

Models F8MTL & G8MTL Multipoise Two

−

Stage

Non

−

Condensing HSI Furnaces

S

Two

−

Stage Heat with Single

−

Stage Gas

−

Heat Thermostat

S

Two

−

Stage Heat with Two

−

Stage Gas

−

Heat Thermostat

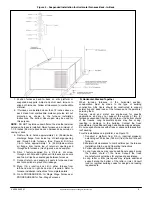

DUCT CONNECTIONS

All furnaces must have a common supply plenum attached to

the furnaces or evaporator coils prior to any branch supply

trunk or take

−

off. The height of the plenum should be at least

as high (upflow/downflow) or as long (horizontal) as the width

of one furnace. Supply air dampers, when used should be

installed in the branch ducts, not in the common plenum. Fire

or smoke dampers, when required by code may be installed in

the common plenum. Refer to the damper manufacturer’s

ratings installation instructions for proper application. The

damper should not create undue restriction in the open

position.

All furnaces must be installed to ensure sufficient return air to

both furnaces:

S

For upflow furnaces:

A combination of one full side of each

and bottom inlet plenum or bottom only inlet plenum shall be

used for return air to each furnace. The preferred method is

to have all return air brought into the bottom of the furnaces

through a common bottom plenum. The bottom return

−

air

plenum shall be at least as high as the width of the furnace

bottom return

−

air opening. When there are height limitations,

the bottom return

−

air plenum height can be reduced to 8 in.

minimum (203mm) if one entire side return

−

air opening of

each furnace is used in conjunction with the bottom return

opening. Rear inlet plenums shall not be used. (See

Figure 1) Connect all return trunks or branch return ducts to

common return plenum.

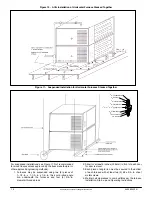

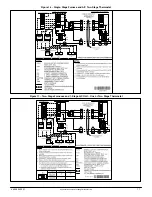

S

For downflow and horizontal furnaces:

All return air must

be brought into the bottom opening of the furnace through a

common return air plenum. The return

−

air plenum shall be at

least as long (horizontal) or tall (downflow) as the width of

the furnace return

−

air opening. (See Figure 2) Connect all

return trunks or branch return ducts to common return

plenum.

S

For all furnaces:

Fire or smoke dampers, when required by

code may be installed in the common return plenum. Refer

to the damper manufacturer’s ratings installation instructions

for proper application. The damper should not create undue

restriction in the open position.

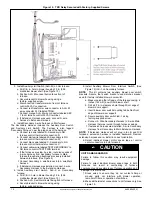

FIRE HAZARD

Failure to follow this warning could result in improper

auxiliary limit operation, fire, personal injury or death.

Do not remove the center return

−

air partitions between

the furnaces.

!

WARNING

Staged heating operation is permitted only with this twinning

kit. With the single

−

speed, non

−

condensing furnaces, the

left

−

hand furnace is used for first

−

stage heat, and both

furnaces are used for second

−

stage heat. With the two

−

stage,

non

−

condensing furnaces, low

−

gas heat in both furnaces is

used for first

−

stage heat, and high

−

gas heat in both furnaces is

used for second

−

stage heat. This kit ensures both furnace

blowers operate simultaneously so air flows through the duct

work rather than recirculating in a loop between the furnaces.