6

443 06 2403 01

Specifications subject to change without notice.

UNIT DAMAGE AND FIRE HAZARD

Failure to follow this warning could result in unit

damage, fire, personal injury or death.

DO NOT use the back or sides of the furnace for

return

−

air duct connections in downflow position, as limit

switch cycling will occur.

!

WARNING

4. Remove bottom closure panels from both furnaces. (See

Figure 4)

a. Lay furnaces on back or sides.

b. Remove 2 screws from bottom front panel.

c. Pull front panel forward to remove.

d. Remove bottom closure panel and discard.

e. Reinstall bottom front panel.

f. Stand furnaces upright.

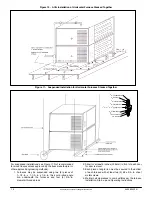

5. Apply 2 factory

−

supplied foam strips to mating side of

each furnace. Locate strips equal distance from top and

bottom as shown in Figure 5. Trim off excess material.

6. Remove 7/8

−

in. diameter accessory hole knock

−

outs in

blower compartment from mating sides of furnaces. (See

Bottom

Closure Panel

Bottom Filler Panel

Figure 4

−

Removing Bottom Closure Panel

Figure 5

−

Location of Foam Strips

7. Insert a plastic snap bushing through the 7/8

−

in.

knock

−

out from the outside of the casing.

8. Bend or remove the supply flanges as required for

upflow or downflow installation. Refer to the furnace

installation instructions for complete details.

9. Position furnaces against each other on return air

plenum, supply air plenum or evaporator coil casing.

Adjust and shim each furnace to align 7/8

−

in. diameter

holes in both furnaces.

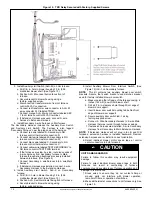

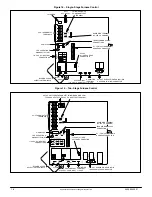

10. Drill two 1/8

−

in. holes, approximately 1 in. (25 mm)below

discharge flange, from inside top of discharge opening

and through both furnaces. (See Figure 6) Drill two

1/8

−

in. holes, approximately 1 in. (25 mm)below return

air flange, from inside top of return air opening and

through both furnaces. (See Figure 7 as an example.)

11. Drive 1 factory

−

supplied screw through each hole and

tighten until furnaces are secure and foam strips have

sealed gap between furnaces.

12. Connect return

−

and supply

−

air ducts to furnaces. Seal

duct connections to prevent air leakage.

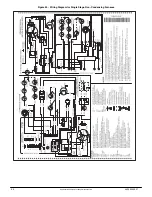

13. Move 115

−

v junction box JB in RH furnace (as viewed

from the upflow position) from left

−

hand side to

right

−

hand side. Refer to furnace installation instructions

for complete details.

14. Go to PROCEDURE 2A for Single Stage Furnaces or

PROCEDURE 2B for Two

−

Stage Furnaces.

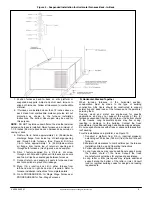

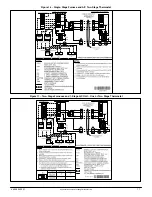

B. Upflow/Downflow, Back

−

to

−

Back Position

Refer to Figure 3 and Table 2 for appearance and dimensional

drawing of twinned furnaces and their connection locations.

1. Select 2 identical heating and airflow furnaces. (See

2. Remove outer door and blower access door.

3. Remove bottom closure panels from both furnaces. (See

Figure 4)

a. Lay furnaces on back or sides.

b. Remove 2 screws from bottom front panel.

c. Pull front panel forward to remove.

d. Remove bottom closure panel and discard.

e. Reinstall bottom front panel.

f. Stand furnaces upright.

4. Applications

A02232

Figure 6

−

Attaching Furnaces Together at Discharge

Opening

a. For upflow applications:

Bottom return air usage is required as part of any

upflow return air configuration. If additional return air

is to enter 1 side of each furnace, in addition to

bottom return air, cut open 1 entire return

−

air