7

443 06 2403 01

Specifications subject to change without notice.

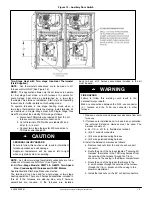

opening in appropriate side of each furnace. (See

UNIT DAMAGE AND FIRE HAZARD

Failure to follow this warning could result in unit

damage, fire, personal injury or death.

DO NOT use the side of the furnace for return

−

air duct

connections, as limit cycling will occur.

!

WARNING

b. For downflow applications:

Return air can only be connected to bottom opening

of furnace. A common return air plenum is required

for proper auxiliary limit switch operation. (See

5. Apply 2 factory

−

supplied foam strips to the back of each

furnace. Locate strips equal distance from top and

bottom as shown in Figure 5. Trim off excess material.

6. Determine which side of furnace will be used to route

external extension harness. Remove 7/8

−

in. diameter

accessory hole knockouts in blower compartment side

selected to attach harness to. (See Figure 3)

7. Bend or remove the supply flanges as required for

upflow or downflow installation. Refer to the furnace

installation instructions for complete details.

8. Position furnaces back

−

to

−

back on return

−

air plenum,

supply air plenum or evaporator coil casing. Adjust and

shim each furnace to align both furnaces.

NOTE

: External extension harness cannot be used on the

same side of the furnace that the return air ducts connect to.

Locate harness on opposite side of furnace when side return

air is used.

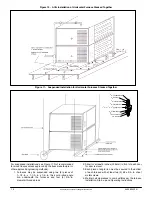

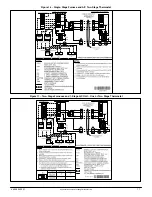

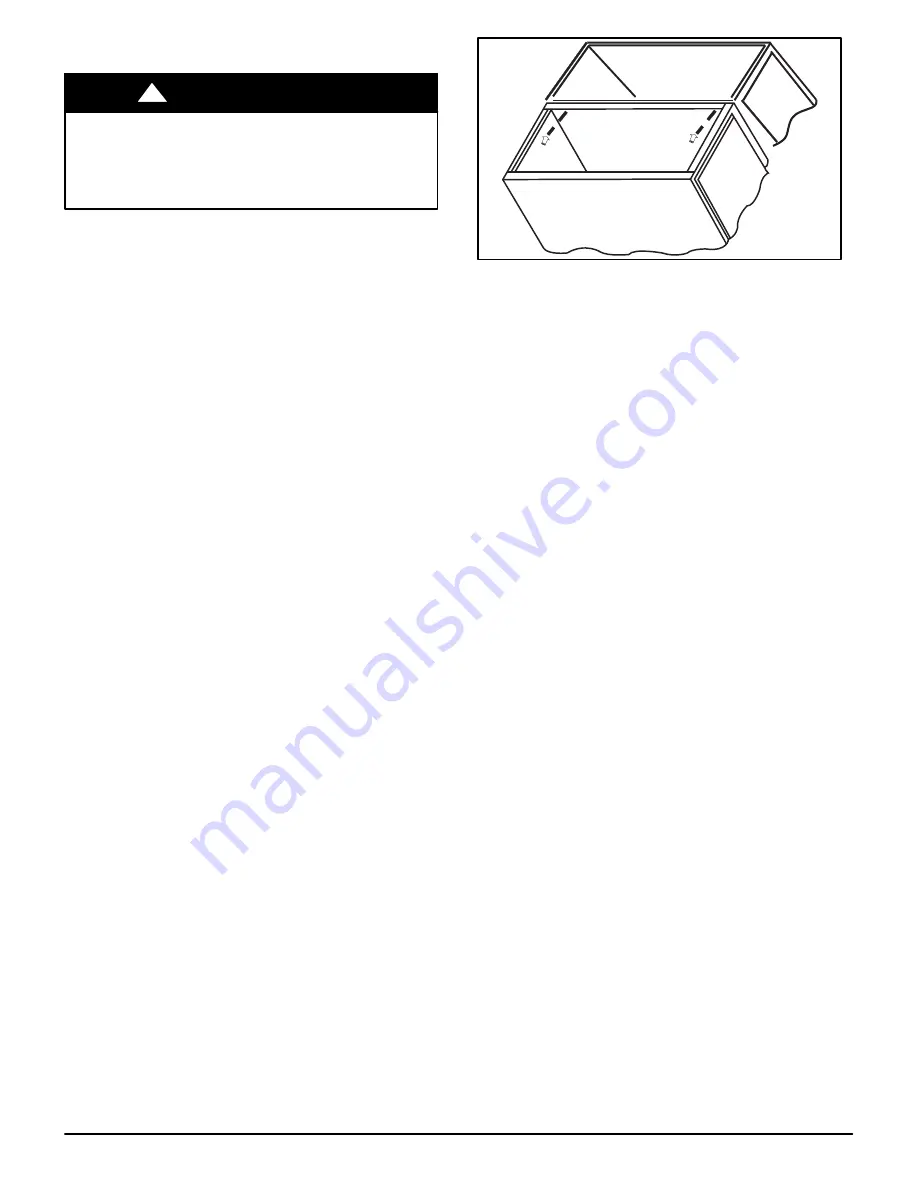

9. Drill two 1/8

−

in. holes, approximately 1 in. (25 mm)below

discharge flange, from inside top of discharge opening

and through both furnaces. (Similar to Figure 6) Drill two

1/8

−

in. holes, approximately 1 in. (25 mm)below return

air flange, from inside top of return air opening and

through both furnaces. (Similar to Figure 7)

10. Drive 1 factory

−

supplied No. 6 X 3/4

−

in. LG screw

through each hole and tighten until furnaces are secure

and foam strips have sealed gap between furnaces.

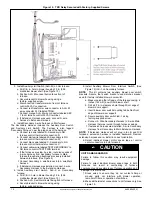

11. Connect return

−

and supply

−

air ducts to furnaces. Seal

duct connections to prevent air leakage.

A02219

Figure 7

−

Attaching Furnaces Together at Return Air

Opening

12. Move 115

−

v junction box JB in either furnace from

left

−

hand side to right

−

hand side if required. Refer to

furnace installation instructions for complete details.

13. Go to Step 2A for Single Stage Furnaces or Step 2B for

Two

−

Stage Furnaces.

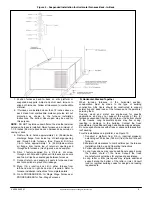

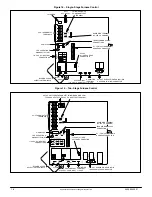

C. Horizontal, Back

−

to

−

Back Position

When twinning furnaces in the horizontal position,

consideration must be made to the type of building

construction. Attic floors should be constructed to support

normal live and dead loads of the furnaces and the person(s)

servicing them.

Trusses, wood and metal are engineered for specific

applications, and may not support the weight of two (2)

furnaces suspended from the top chords or the bottom chords

of the trusses. Long horizontals spans may flex or sag,

resulting in damage to the building. Contact the truss

manufacturer for additional design and engineering assistance.

Do not suspend furnaces with straps or suspend furnaces from

roof decking.

For attic installations on a platform (See Figure 8):

1. Construct a platform from 3/4

−

in. (76 mm) (nominal

plywood), extending out 30 inches (762 mm) from the

front of each furnace.

2. Maintain all clearances to combustibles per the furnace

Installation, Start

−

up and Operating Instructions.

3. Follow all additional building codes.

4. Long truss spans may require additional support along

the bottom chord of the truss. Consult the truss

manufacturer’s guidelines for engineering assistance.

5. Long rafter or attic joist spans may require additional

support along the bottom of the rafter or joist. Consult

local or regional building codes for design and loading

requirements.