22

minutes duration. The exhaust will have a pungent odor

and produce a white cloud of steam.

3.4)

Perform the smoke / CO2 test:

1. For chimney installations, pierce a test hole in the

smoke pipe near the furnace breech. For side-wall

vented installations, remove the threaded cap from

the extended test pipe that is welded into 4-bolt

breech plate. Insert the smoke test instrument

probe into the open hole.

2. Starting with a zero smoke reading, gradually

reduce the burner air setting until just a trace (#1 on

Bacharach Scale) of smoke results.

3. Take a CO2 sample at the same test location

where the smoke sample was taken. Note the CO2

reading associated with the #1 smoke condition.

4. For chimney vented installations, adjust the burner

air setting to obtain a CO2 reading 1% lower than

the reading associated with the #1 smoke.

5. For side-wall vented installations, adjust the burner

air setting to obtain a CO2 reading 1.5% lower than

the reading associated with the #1 smoke.

1. This method of adjusting the CO2 will allow

adequate excess air to ensure that the burner will

burn clean for the entire heating season, and will

ensure proper calibration of the DV-2000™ blocked

intake/ vent safety shutdown system used in side-

wall venting applications.

3.5)

Perform the supply air temperature

rise test:

1. Operate the burner for at least 10 minutes.

2. Measure the temperature of the air in the return air

plenum.

3. Measure the temperature of the air in the largest

trunk coming off the supply air plenum, just “out of

the line of sight” of the radiation coming off the heat

exchanger; 12” away from the plenum on the main

take-off usually satisfies this objective.

4. The temperature rise is calculated by subtracting

the return air temperature from the supply air

temperature.

5. If the temperature rise exceeds the temperature

specified in table #4.1 to #4.3, change to the next

higher blower speed tap until the temperature rise

falls to at this temperature or below. If the excessive

temperature rise cannot be reduced by increasing

fan speed, investigate for ductwork restriction(s),

dirty or improper air filter, or overfiring caused by

excessive pump pressure, or inproper nozzle

sizing.

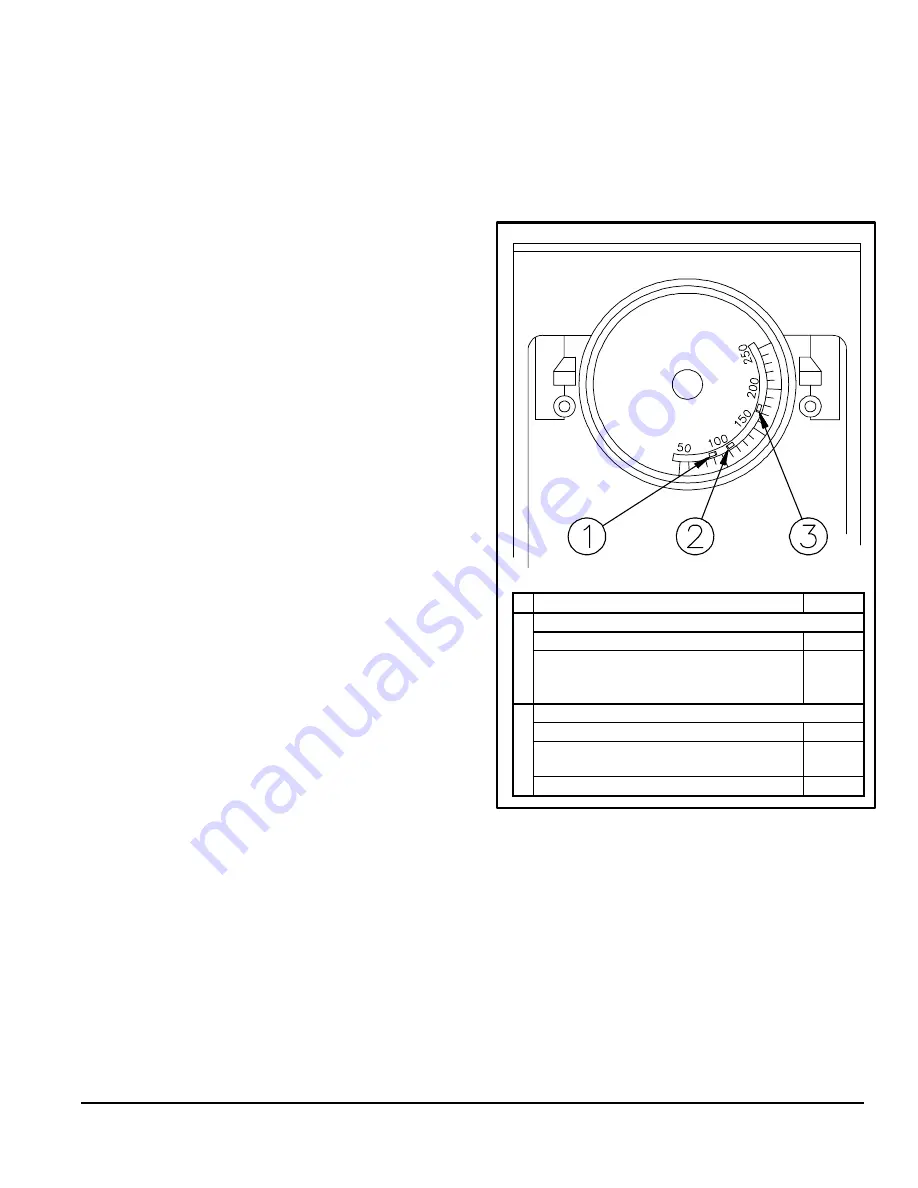

3.6)

Fan limit adjustment:

FIGURE # 4

1

Limit “FAN OFF”

90

0

F

2

Limit “FAN ON”

Model : OLR160

110

0

F

Model : OUF105, OLF105, OLR105,

OUF160, NOUF105, NOLF105 &

NOUF160

130

0

F

3

Limit “HI”

Model: OLR160

170

0

F

Model: OUF105, OLF105, OLR105,

NOUF105 & NOLF105

180

0

F

Model: OUF160 & NOUF160

220

0

F

3.7)

Vent temperature test:

1. Place a thermometer in the test hole located in the

breech pipe.

2. The vent temperature should be between 400 and

575

°

F. If not, check for improper air temperature

rise, pump pressure, nozzle size, or for a badly

sooted heat exchanger.

DNS-0355 Rev.B

Summary of Contents for OLR Series

Page 29: ...DNS 0571 Rev B DNS 0573 Rev B 30 FIGURE 5 1 Model OLR105A12B FIGURE 5 2 Model OLR160B20B...

Page 30: ...31 FIGURE 5 3 Model OUF105A12B FIGURE 5 4 Model OUF160B18 DNS 0568 Rev C DNS 0572 Rev C...

Page 31: ...FIGURE 5 5 Model OLF105A12B DNS 0570 Rev B FIGURE 5 6 Model NOUF105A12B 32 DNS 0674 Rev C...

Page 32: ...33 FIGURE 5 7 Model NOUF160B18B FIGURE 5 8 Model NOLF105A12B DNS 0676 Rev C DNS 0675 Rev D...