GW-7238D J1939 to MBTCP Server / MBRTU Slave Gateway User’s Manual (Ver.1.0, Nov. 2011) --- 51

6. Troubleshooting

Item

Trouble state

Solution

1

CAN Bus Transmission Fail

(Power LED Blink per 100 ms)

Make sure the CAN bus wiring is

connected, and connected to the

correct pin.

2

CAN Bus-Off

(Power LED Blink per 500 ms)

Make sure the CAN bus wiring

does not short-circuit

3

Can’t Claim Address in J1939

Network

(Power LED Blink per 1000 ms)

Please configure another J1939

network address in GW-7238D

Utility.

4

Can not transmit the output

J1939 message

1. Make sure the Start/Stop

sending J1939 output

message register (42009) is

0x00.

2. Make sure the Update Rate of

J1939 output message table is

not zero.

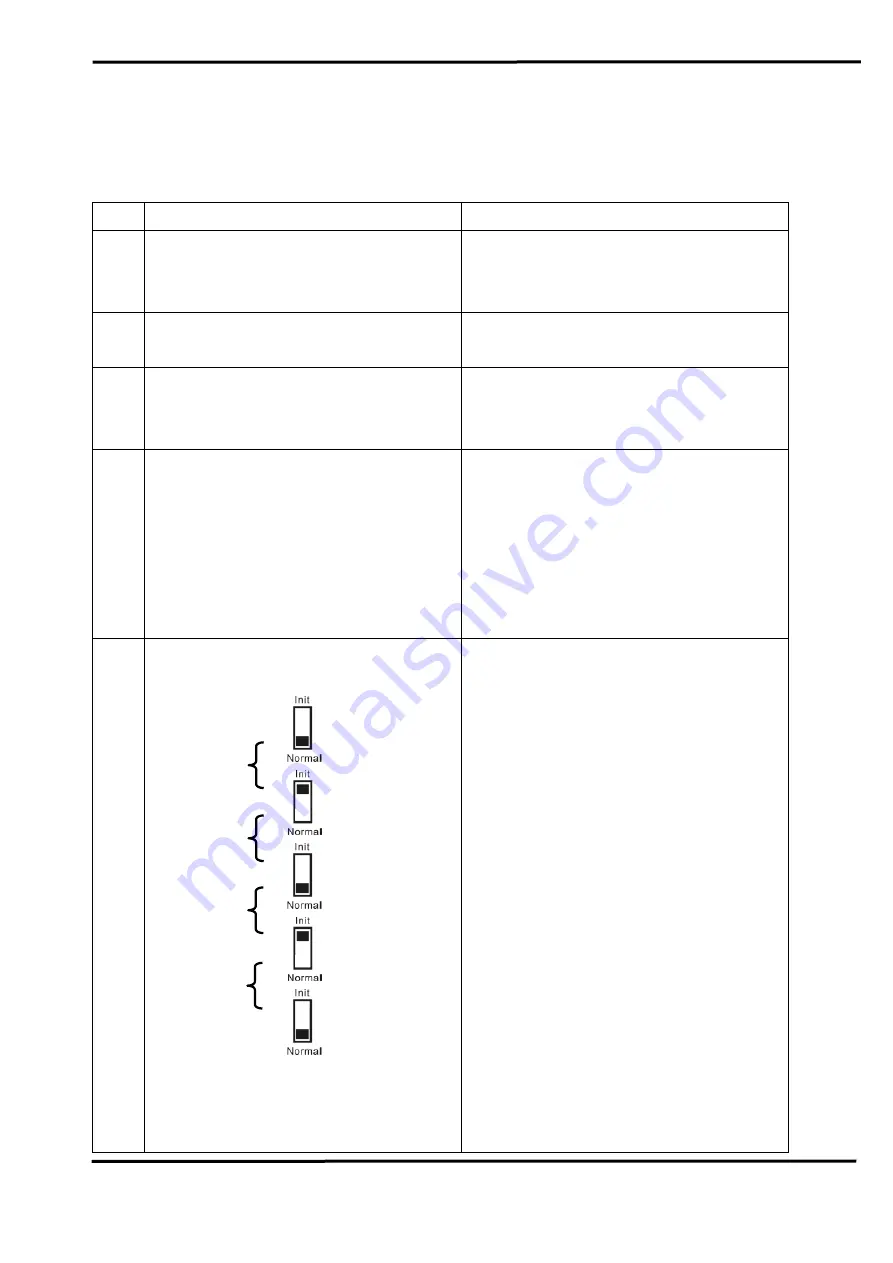

5

How to restore factory default

1. Power on the GW-7238D

2. Change the Dip-Switch

position of the GW-7238D and

to complete the following steps

in 5 seconds.

Step1. From “Normal” to “Init”

position.

Step2. From “Init” to “Normal”

position.

Step3. From “Normal” to “Init”

position.

Step4. From “Init” to “Normal”

position.

3. When the correct

implementation of the above

steps, the J1939/Modbus

LEDs of the GW-7238D should

be turn on, and that should be

turn off after 500 ms later.

Step1

Step2

Step3

Step4