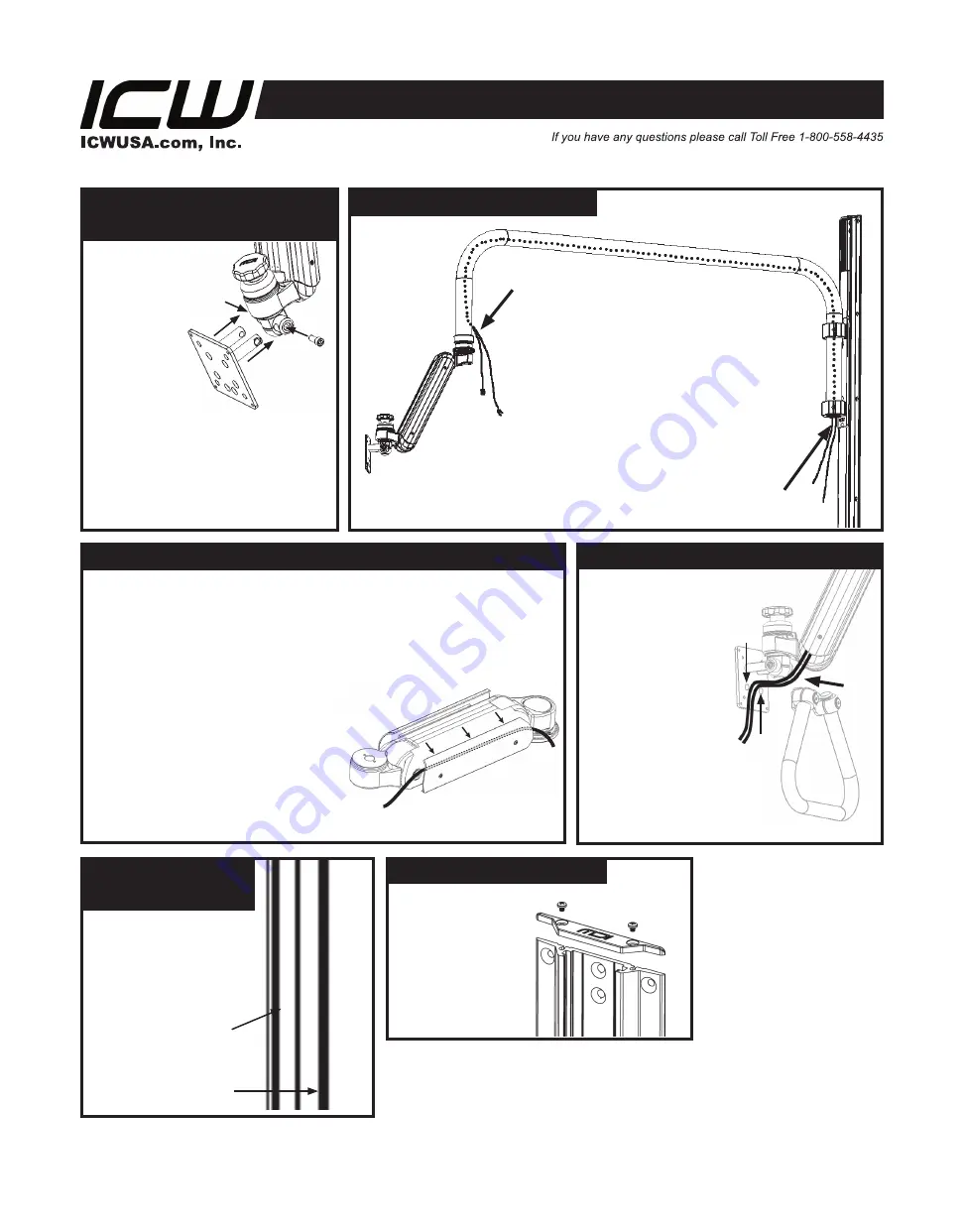

OVERHEAD ARM INSTALLATION 01/20/16 pjm

overhead arm installation

Page 2 of 4

overhead arm installation

attaCh vesa With monitor

to arm

•

Slide posts

of VESA plate

into the EV65 joint assembly.

•

Insert provided socket head cap

screws into both sides of EV65

and tighten.

•

Use knob to adjust tilt friction.

NOTE: Monitor is

not shown in order

to illustrate mounting

detail.

Use cord provided inside overhead arm

to pull wires through to the monitor.

•

At track end of overhead arm, grasp cord

and pull down.

•

Loop cord around wires.

•

At monitor end of overhead arm, grasp

cord and pull wires through.

PUll Wires throUGh arm

Loop cord around

wires at this end

Pull wires through

arm at this end

rUn Wires throUGh Ultra 182 to monitor

•

The Ultra 182 cover plate is spring loaded. Loosen cover

plate screws on side of arm just enough to fit wires through

gap. Run wires loosely between cover plate and arm.

Wires can be run on either or both sides of the arm.

•

Connect wires from Ultra 182 to monitor.

•

Move monitor through full range of motion to

allow for correct amount of slack in wire.

Pull excess wire back through

Ultra 182 and overhead arm.

•

Push cover plate against Ultra 182

arm and tighten screws, being

careful not to pinch wires.

reattaCh BeaUtY CaPs

Reattach plastic

caps to top and

bottom of track.

rUn Wires

throUGh traCK

•

Pull slack wire down

from overhead arm.

•

Run wires through

center of track.

•

Reattach track cover.

Track cover

Wires run through

center of track and

out the bottom

attaCh handle to vesa Plate

Center wires

between screw

holes on VESA

plate where handle

attaches. Using

socket head

screws provided,

attach handle to

VESA plate,

securing wires

between handle

and back of VESA

plate.