OVERHEAD ARM INSTALLATION 01/20/16 pjm

overhead arm installation

Page 3 of 4

overhead arm installation

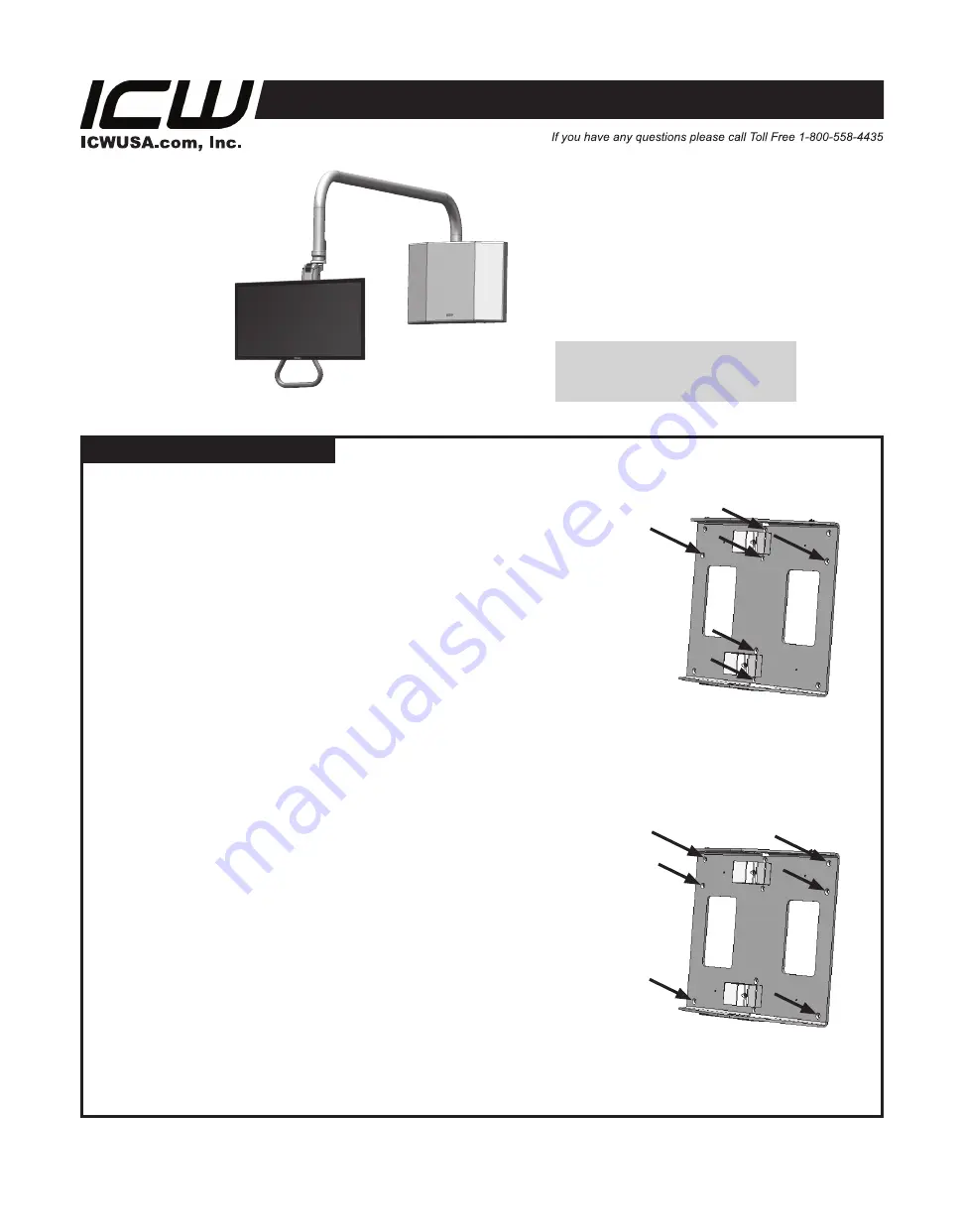

moUnt Wall Plate to Wall

MAXIMUM LOAD CAPACITY:

28 Lbs (12.7 kg)

CENTEr MOUNTED ON ONE sTUD

(16” or 24” spaced studs)

Locate a stud in the wall where wall plate will be mounted, determine desired height,

and mark the top (center) hole.

For wood studs:

•

Drill 11/64” pilot hole and insert #14 wood screw (provided), tighten slightly.

•

Using a level, mark the remaining 3 holes in the center of the plate and one hole in

each edge of the plate. Remove the plate and pilot each hole.

•

Following the Snaptoggle installation instructions on next page, install Snaptoggles

in the two edge holes. Replace plate using 4 #14 screws and 2 ¼-20x2-1/4” flat

Phillips head machine screws. Check level and tighten all 6 screws.

For steel studs:

•

Drill 11/64” pilot hole, then follow Snaptoggle installation instructions on next page.

• Attach plate using ¼-20x2-1/4” flat Phillips head machine screw, tighten slightly.

•

Using a level, mark the remaining 3 holes in the center of the plate and one hole in

each edge of the plate.

•

Remove the plate, pilot, and install Snaptoggles in all 5 holes.

• Replace plate using 6 ¼-20x2-1/4” flat Phillips head machine screws. Check level

and tighten all 6 screws.

sPANNINg TwO sTUDs

(16” spaced studs only)

Locate two studs in the wall where wall plate will be mounted, determine desired

height, using a level, mark the top hole in each edge of the plate.

For wood studs:

•

Drill 11/64” pilot holes and insert 2 #14 wood screws (provided), tighten slightly.

Using a level; pilot the remaining 4 holes in the edges of the plate and insert #14

screws. Check level and tighten all 6 screws.

For steel studs:

•

Drill 11/64” pilot holes then follow Snaptoggle installation instructions on next page,

attach plate using 2 ¼-20x2-1/4” flat Phillips head machine screws, tighten slightly.

Using a level; mark the remaining 4 holes in the edges of the plate.

•

Remove the plate, pilot, and install Snaptoggles in all 4 holes.

• Replace plate using 6 ¼-20x2-1/4” flat Phillips head machine screws. Check level

and tighten all 6 screws.

Ul182-ohaP

Wall Plate mount