ULTRA ARM INSTALLATION - 5/21/20

Page 3 of 4

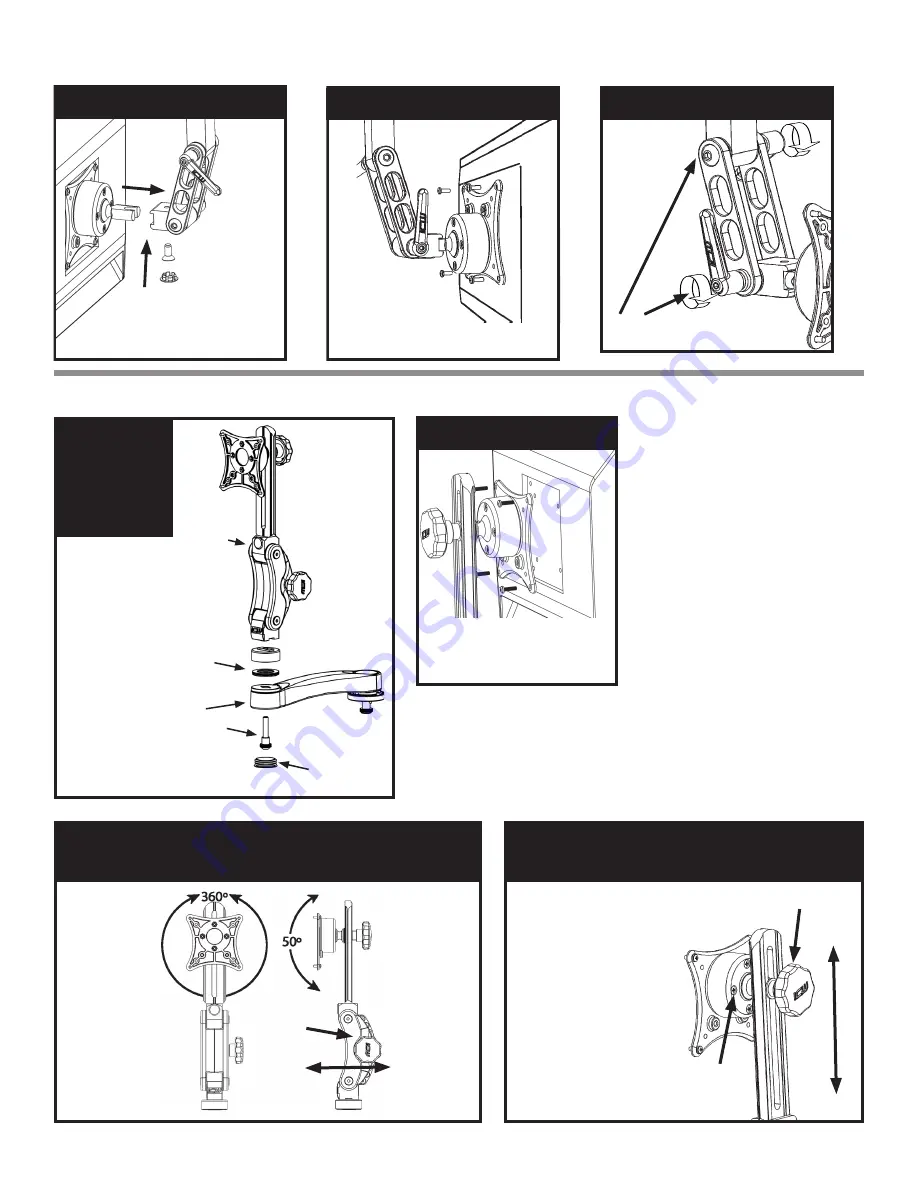

ATTACH VESA TO UL 500

Mount the

VESA assembly

to the friction

mount by sliding

the connecter into the UL500

pivot block. Using the 5/32” hex

key, secure fl at head screw back

into place.

ATTACH VESA TO MONITOR

Attach the

VESA plate to

your monitor

using the four

4mm screws in

the hardware bag.

ADJUST TILT HANDLES

Use the handles to adjust

the tilt of the monitor.

IF USING UL550

IF USING UL500

ATTACH TO MONITOR

Attach your monitor to the VESA

plate user the four 4mm screws in

the hardware bag.

MONITOR TILT, ROTATION

& ADJUST MONITOR DEPTH

MONITOR TILT

& ROTATE

Gently hold sides

of monitor. Tilt and

rotate to desired

position with ball

VESA.

ADJUST

MONITOR

DEPTH

Loosen the

adjustment

knob, move

the Paralink

forward or

back, then

re-tighten

the knob.

Adjustment

Knob

Pivot tension

adjustment

screws

Use the slider knob to

loosen the slider to adjust

the height of the monitor

on the Paralink.

Adjust the pivot tension

of the ball by gently and

evenly tightening or

loosening the four

screws on the back

of the ball VESA.

Slider knob

ADJUST BALL VESA

TENSION & HEIGHT

ATTACH

PARALINK

TO W2,

W3 OR W5

Attach to Paralink

to Ultra arm using

3/8 bolt assembly

and 1.25” bearing

assembly provided.

Insert bolt assembly

up through wall ear.

Place 1.25” bearing

assembly over bolt

on the other side

of wall ear. Place

Paralink over bolt

and bearing and turn

bolt until Paralink is

secure and smoothly

turns against the

bearing.

Paralink

1.25”

ID bearing

assembly

3/8 bolt

assembly

W2

Beauty cap