ULTRA ARM INSTALLATION - 5/21/20

Page 4 of 4

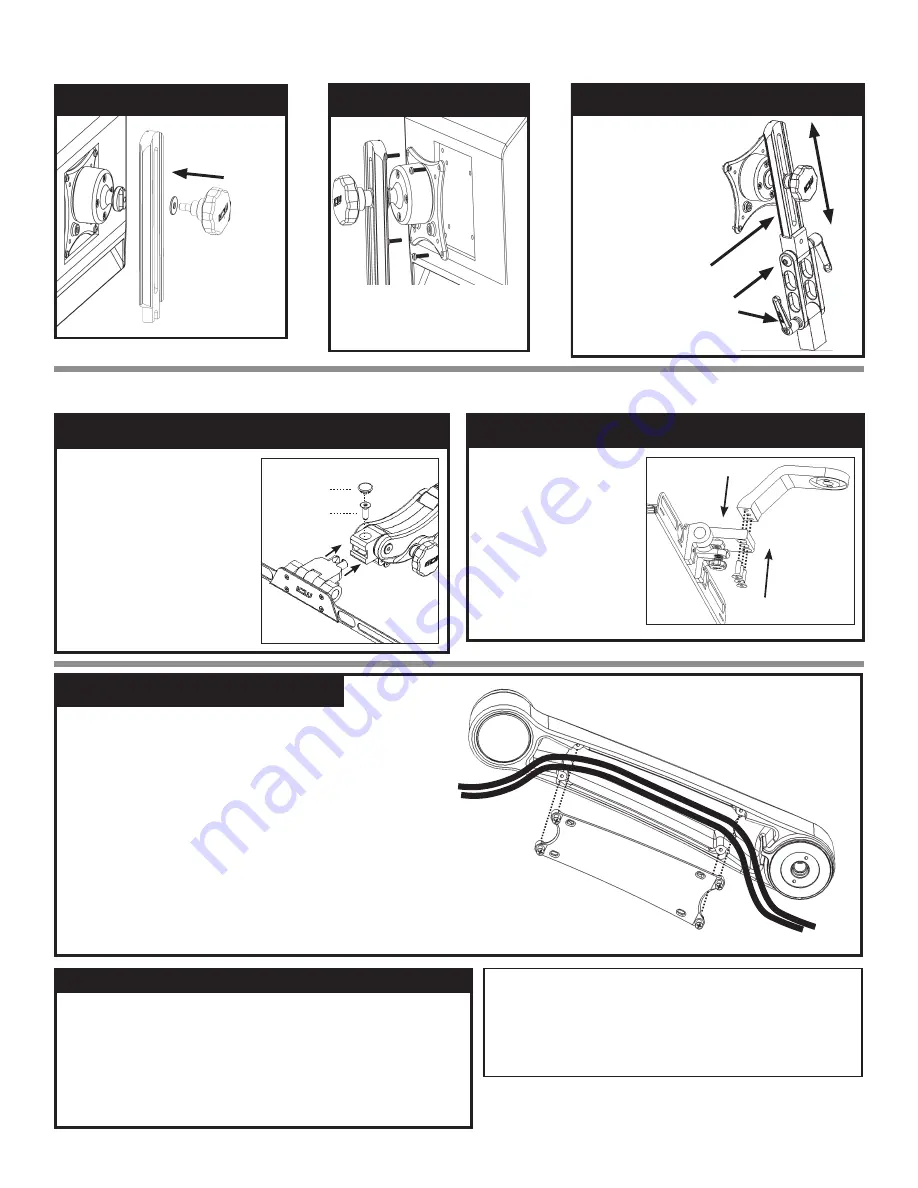

ULTRA CORD MANAGEMENT

1. Prepare all cables to route within the arm by placing them

near cavity of arm and bundling together if necessary.

2. Remove cover by unscrewing four socket head cap screws.

Screws are captured by the cover so they cannot fall out.

Once screws are disengaged, pull cover out of arm.

3. Place cables within the channel. Do not block the holes

where screws will engage in arm.

4. Replace cover and tighten screws. Cables should be able to

pull through to desired position if necessary.

IF USING PARALINK KEYBOARD TRAY

IF USING ULTRA KEYBOARD TRAY

IF USING UL510

ADJUST TILT & MONITOR HEIGHT

Use the handles to

adjust the tilt of the

monitor.

Adjust the height of

the monitor along

the rails of the 510.

Then tighten in

place using slider

knob.

Slider Knob

ATTACH VESA

Mount the VESA

assembly to the slide

rail by screwing in

the knob through the

rail into the VESA

assembly as shown.

ATTACH TO MONITOR

Attach your monitor to the VESA

plate user the four 4mm screws in

the hardware bag.

ATTACH FLIP UP

1. Remove screws from

drop extension using

5/32” hex key.

2. Align holes in keyboard

tray with screw holes in

drop extension.

3. Attach keyboard tray

using the provided

screws.

ATTACH PARALINK

1. Remove beauty cap on

Paralink.

2. Remove screw using 3/16”

hex key.

3. Slide keyboard tray into

Paralink.

4. Replace screw and tighten.

5. Replace beauty cap.

Beauty cap

Screw

NOTICE: ICWUSA.COM, Inc. provides the appropriate hardware fasteners to

match the majority if not all standard monitors and devices. It is the responsibility

of the installer / integrator to ensure that the screws and fasteners have the

adequate thread engagement. The rule of thumb is that the thread depth is greater

than the diameter of the hole or 4 full turns of 360 degrees of thread engagement.

It is also the responsibility of the installer / integrator to ensure that they do not

damage the monitor or device by using a screw or fastener that is too long for hole

and therefore damaging the unit by inserting too far.

When cleaning your ICW mounting unit please follow the points below. Proper

cleaning of the mounting device will help assure proper function and extend the

life of the unit.

1. Any general cleaner is acceptable except degreasers are not recommended near

the bearing entrances.

2. Spray cleaner or water on a soft cloth or paper towel and then wipe down

the mounts.

3. Do not spray directly at the bearing seams (located at all swivel points) as this could

reduce the life of the bearings.

CLEANING OF THE ICW MOUNTING DEVICE