Model 252

Label Printer/Applicator

Operators/Technical Manual

53

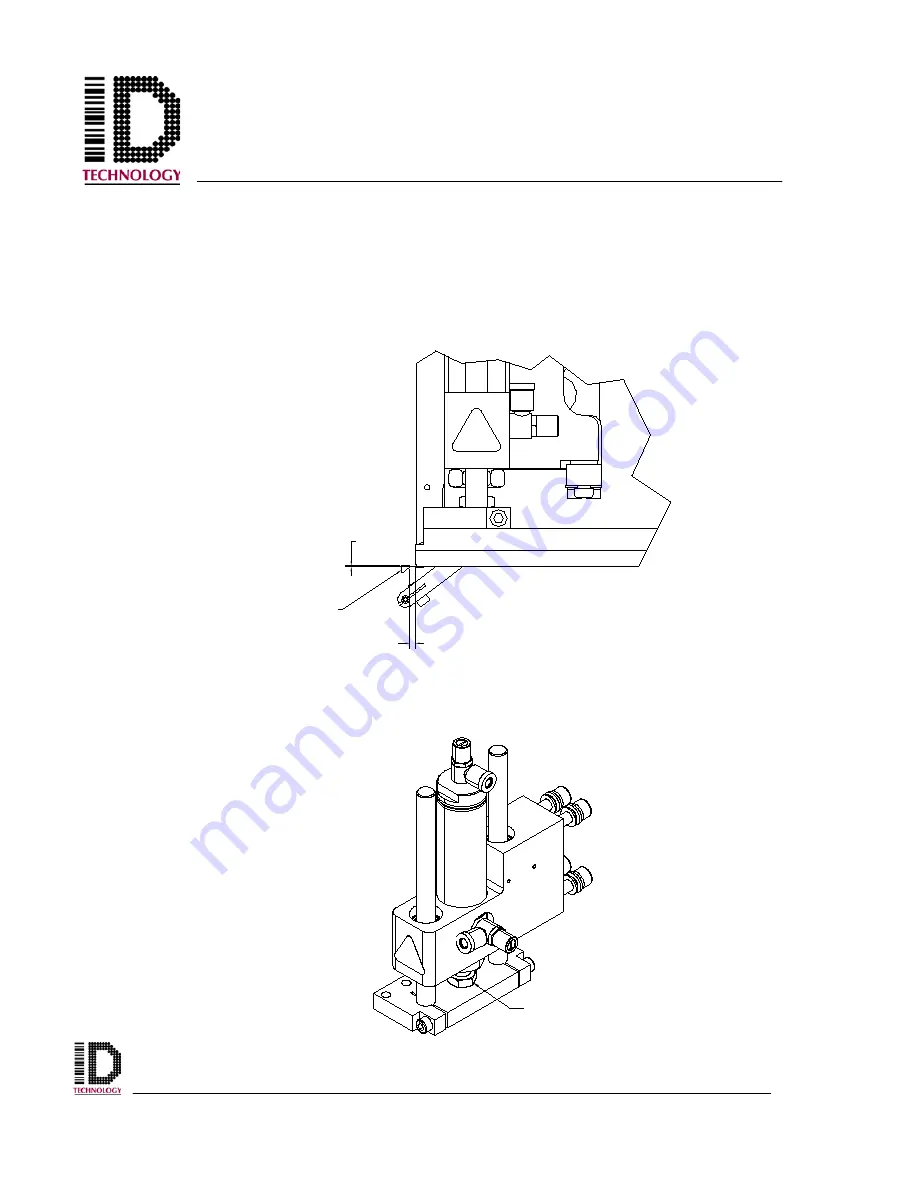

5.14 Setting up Tamp Applications

5.14.1 Setting the Tamp Position

Begin by loosening the four M8 bolts holding the tamp module to the faceplate using a

6mm hex wrench. Slide the tamp module in the mounting slots until the tamp pad is

approximately 1/8” from the peel tip. Be sure the tamp module is straight up and down

then re-tighten the mounting bolts.

With the cylinder all the way home, note the position of the chamfer to the peel edge.

The top surface of the peel plate should, if drawing an imaginary line, intersect the tamp

pad midway up the chamfer (the angled cut across the front edge). If the position is not

correct, use a small adjustable wrench to loosen the cylinder adjust nut.

1/8"

HALF OF

CHAMFER

PEEL EDGE

CYLINDER

ADJUST NUT

Summary of Contents for 252

Page 1: ...Model 252 Label Printer Applicator Operator Technical Manual...

Page 10: ...I GENERAL...

Page 19: ...II OPERATING FUNDAMENTALS...

Page 25: ...III INITIAL SETUP...

Page 28: ...Model 252 Label Printer Applicator Operators Technical Manual 3 1 12 Declaration of Conformity...

Page 116: ...Model 252 Label Printer Applicator Operators Technical Manual 0 V DRAWINGS AND DIAGRAMS...

Page 160: ...VI COMPONENT INFORMATION...

Page 161: ...Model 252 Label Printer Applicator Operators Technical Manual 1 MiniBeam Photocell...

Page 162: ...Model 252 Label Printer Applicator Operators Technical Manual 2...

Page 163: ...Model 252 Label Printer Applicator Operators Technical Manual 3...

Page 164: ...Model 252 Label Printer Applicator Operators Technical Manual 4...