Supplied By www.heating spares.co Tel. 0161 620 6677

6

British Gas RD1

-

Installation & Servicing

GENERAL

This appliance is NOT suitable for use in a direct hot water system.

1.

If the boiler is to be used for gravity domestic hot water supply then cut off the spun

ends of the gravity flow and return pipes and fit the 22 mm to 28 mm copper

compression fittings (provided in the Hardware Pack) at the boiler gravity flow and

return connections, in order to run the gravity circuits in 28 mm pipe.

Note.

The 100 is

not suitable for gravity circulation.

2. 70 to 100 ONLY

must be fitted with the 22mm x 28mm copper compression fittings, provided in the

Hardware Pack and the pumped flow and return pipes run in 28mm pipe.

3.

The boiler is suitable for use on a sealed system. An Overheat Thermostat is fitted as

standard.

1

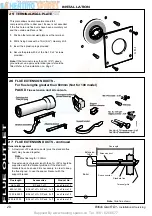

BOILER WATER CONNECTIONS

The following minimum clearances

must be maintained for servicing.

Additional space will be required for

installation, depending upon site

conditions.

Side and Rear Flue

a.

Provided that the flue hole is cut

accurately, e.g. with a core drill, the

flue can be installed from inside the

building.

Installation from inside ONLY

b.

If a core boring tool is to be used

inside the building; the space in

which the boiler is to be installed

must be at least wide enough to

accommodate the tool.

c.

If using the Complete Sealed

System Unit then refer to the

instructions packed with the unit for

the necessary clearances.

Pelmet restrictions.

If the ability to fit or remove the

casing during installation and

subsequent servicing is impaired

by pelmets etc. this operation can

be made easier by first removing

the controls support casing in line

with the following instructions:

a.

Release the controls pod

casing fixing screws (a) 3 full

turns only. Remove the

support by pulling it forward to

disengage from the keyhole

slots.

b.

Undo the 2 screws (b)

retaining casing to the back

panel.

c.

The casing can now be

removed in the direction of the

arrow, first lifting the casing

slightly to disengage the

casing top return from the

back panel. (For this purpose

a minimum clearance of

12mm is required between the

top of the boiler and pelmet or

other similar obstruction.

Front clearance: 533mm (21") from

the front of the boiler casing.

Minimum front clearance when built

in to cupboard is 75 mm (3").

380 (15")

300 (12")

Pumped

return

pipe

Pumped flow pipe

12 (1/2")

100

(4")

44

(1 3/4")

Flue

terminal

300 (12")

Jacking

screw

Gas

connection

700

(27 1/2")

141

(5 9/16")

Clas 1786

Front View

Side View

133 (5 1/4")

44 (1 3/4")

20 (3/4")

Gas

connection

190 (7

1/2

")

Flow

Gravity

Return

flue

2 BOILER CLEARANCES