18

British Gas 440 - 480 RD2 -

Installation & Servicing

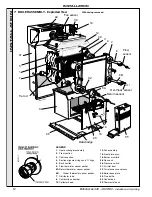

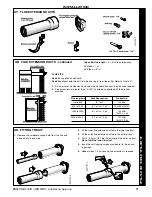

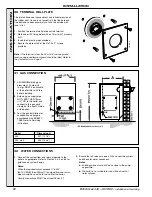

INSTALLATION

FLUE OUTLET

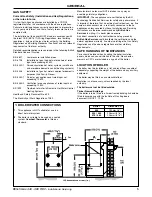

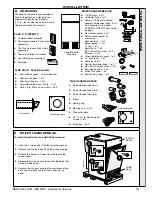

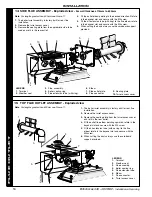

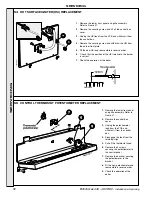

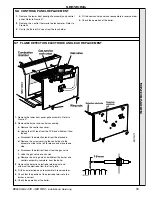

19 FITTING BOILER SEALING RING TO THE FLUE - Top

1. Fit the boiler sealing ring inside the appropriate

length (A) of outer flue duct (refer to Frame 11).

Ensure the boiler sealing ring is fully engaged.

2. Drill 3 holes 3.2mm (

1/8

") dia. through the outer flue

duct and boiler sealing ring.

Do not drill the inner

flue duct

.

3. Insert the self tapping screws, provided, in order to

fix the boiler sealing ring in position.

4. Fit the turret access cover to the sealing ring.

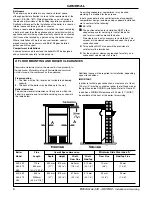

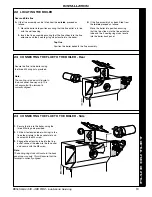

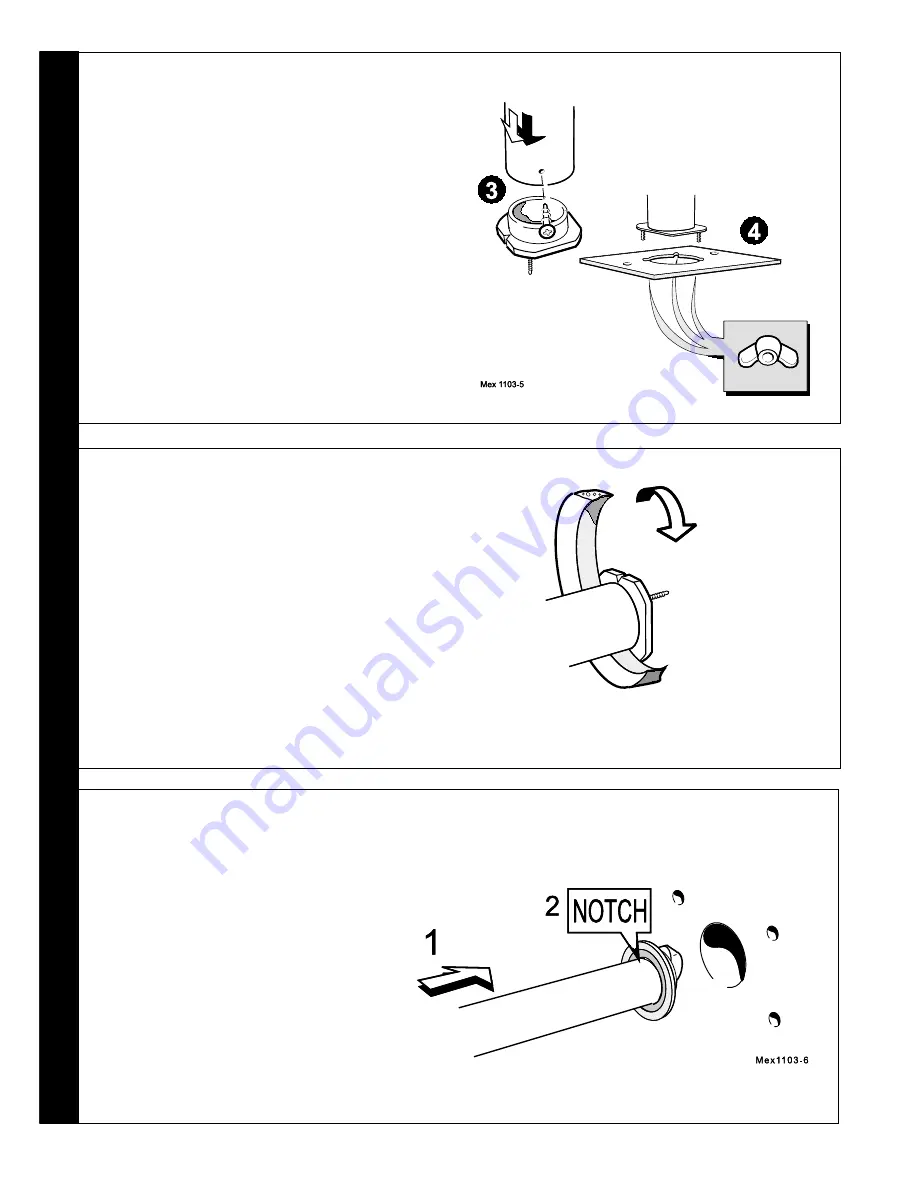

1. To determine the position for the foam seal

measure the wall thickness and mark it onto

the flue, measuring from the groove near the

terminal.

2. Wrap the self-adhesive foam strip round the

flue, ensuring that the foam is on the terminal

side of the line. This seals the gap between

the flue and the wall.

20 FITTING THE FOAM SEAL

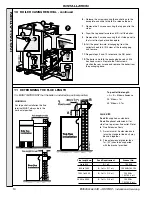

21 FITTING THE FLUE ASSEMBLY

A. Inside fitting.

If the flue assembly cannot be fitted from the outside,

proceed as follows:

1. Insert the flue assembly through the hole far

enough to allow the rubber seal to unfold

completely and form an adequate seal on the

outside wall.

2. Ensure the notch is at the top. This will aid the

location of the studs into the boiler back panel.

3. Proceed to Frame 22, item B.

B. Outside fitting.

Proceed to Frame 22, item A.

FLUE OUTLET