22

British Gas 440 - 480 RD2 -

Installation & Servicing

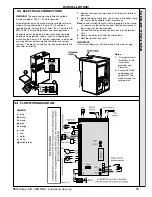

INSTALLATION

2. Ensure that all valves are open. Fill and vent the system

and check for water soundness.

Notes.

a.

Isolating valves must be fitted as close to the pump

as possible.

b.

The boiler is not suitable for use with a direct hot

water cylinder.

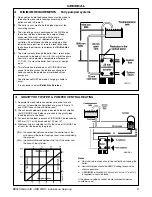

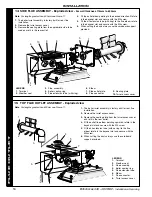

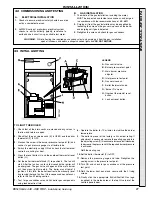

32 WATER CONNECTIONS

1. Connect the system flow and return pipework to the

boiler as appropriate. Refer to Frames 3, 4, 5 and 6 for

guidance on system design.

Notes.

When the required output exceeds 17.6 kW

(60 000 Btu/h) then 28mm (1") pumped flow and return

pipes should be used, both to and from the boiler.

Gravity connections MUST be at least 28mm (1").

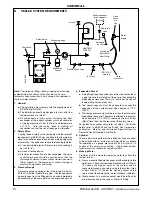

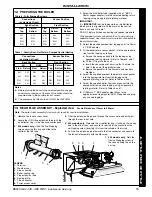

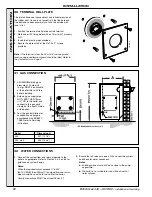

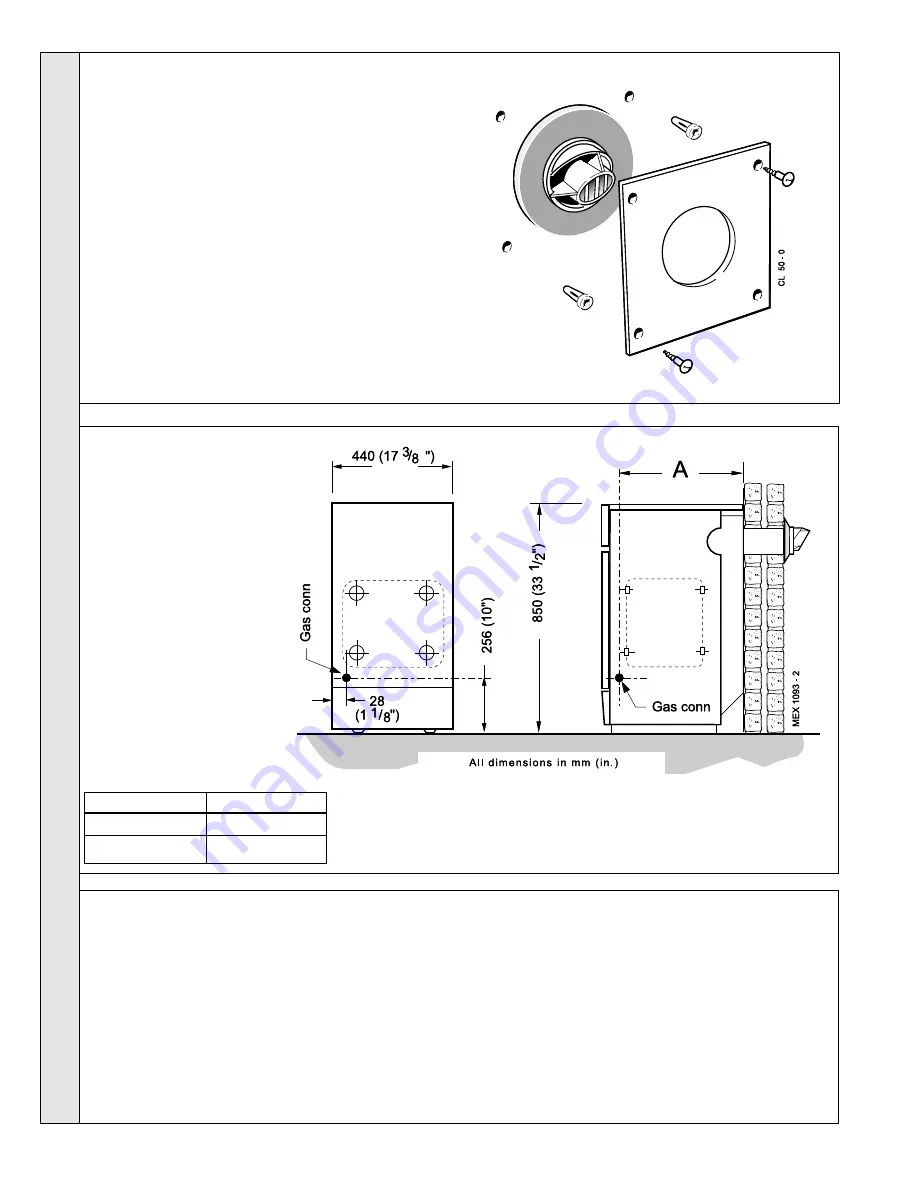

31 GAS CONNECTION

1. A MINIMUM working gas

pressure of 20 mbar (8

in.w.g.) MUST be available

at the boiler inlet, with the

boiler operating.

2. Extend a gas supply pipe

NOT LESS THAN 15mm

(

1/2

") OD to the boiler and

connect to the gas cock

situated at the front LH side

of the boiler.

3. Test the gas installation for

soundness and purge in

accordance with BS.6891:

1988. Refer to Servicing

instructions.

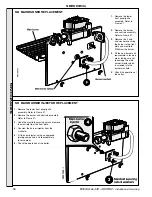

Boiler

Dimension A

440

327 (12

7/8

")

450 - 480

400 (15

3/4

")

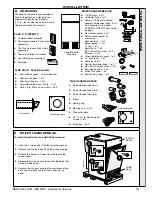

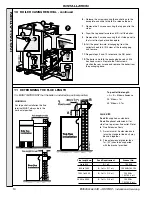

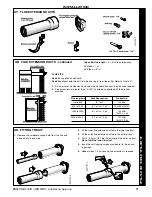

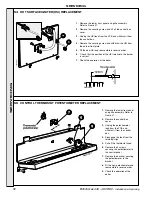

30 TERMINAL WALL PLATE

This plate allows neat concealment and full compression of

the rubber seal. Its use is not essential if the flue hole and

flue ducts have been accurately cut and the outside wall

face is flat.

1. Position the terminal wall plate over the terminal.

2. Mark and drill 4 fixing holes with an 7mm (

9/32

") masonry

drill.

3. Insert the 4 plastic plugs provided.

4. Secure the plate with 4 of the No.10 x 2" screws

provided.

Note.

If the terminal is less than 2m (6' 6") above ground

level, an approved terminal guard should be fitted. Refer to

the Contents List on Page 4.

INST

ALLA

TION