8

British Gas 440 - 480 RD2 -

Installation & Servicing

GENERAL

Water Flow Rate and Pressure Loss

WATER TREATMENT

The boiler incorporates a cast iron heat exchanger. As part of

the installation the central heating system should be thoroughly

flushed with appropriate water treatment in order to comply with

BS7593:1992

British Gas Services recommend the use of Fernox or Betz

Dearborn water treatment products which must be used in

accordance with the manufacturers instructions. For further

information contact :

Fernox Manufacturing. Co. Ltd., Tandem House, Marlowe

Way, Croydon, Surrey CRO 4XS, tel 0870 601 5000

or

Betz Dearborn Ltd., Widnes, Cheshire, tel. 0151 424 5351

IMPORTANT.

ANY OTHER TREATMENT FOR THIS PRODUCT MAY

RENDER THE GUARANTEE OF BRITISH GAS SERVICES

INVALID.

Notes.

1. If an inhibitor is used, and in hard water areas where

treatment to prevent lime deposits is necessary, it is most

important that the water treatment MUST be maintained at

the correct concentrations recommended by the treatment

manufacturer.

2. Artificially softened water must not be used in the system,

under any circumstances.

THERMOSTATIC RADIATOR VALVES

British Gas Services recommend that heating systems utilising

full thermostatic radiator valve control of temperature in

individual rooms should also be fitted with a room thermostat

controlling the temperature in a space served by radiators not

fitted with such a valve, as stated in BS. 5449.

When thermostatic radiator valves are used, the space heating

temperature control over a living / dining area or hallway having

a heating requirement of at least 10% of the boiler heat output

should be achieved using a room thermostat, whilst other rooms

are individually controlled by thermostatic radiator valves.

However, if the system employs thermostatic radiator valves on

all radiators or two port valves without end switches then a

bypass must be fitted in order to ensure a flow of water should

all the valves be in the closed position.

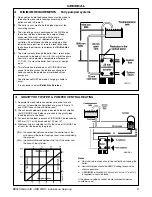

ELECTRICAL SUPPLY

WARNING. The appliance MUST be efficiently earthed.

Wiring external to the appliance MUST be in accordance with

the current I.E.E. (BS 7671) Wiring Regulations and any local

regulations which apply.

The boiler is supplied for 230 V ~ 50 Hz single phase. The fuse

rating is 3A.

Connection must be made in a way that allows complete

isolation of the electrical supply - such as a double pole switch,

having a 3mm (

1/8

") contact separation in both poles, or a plug

and socket serving only the boiler and system controls.

The means of isolation must be accessible to the user after

installation.

For bathroom installations the point of connection to the mains

must be situated outside the bathroom.

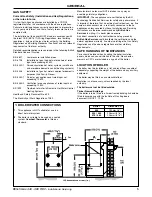

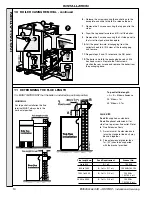

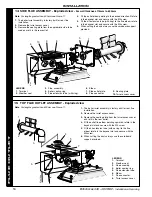

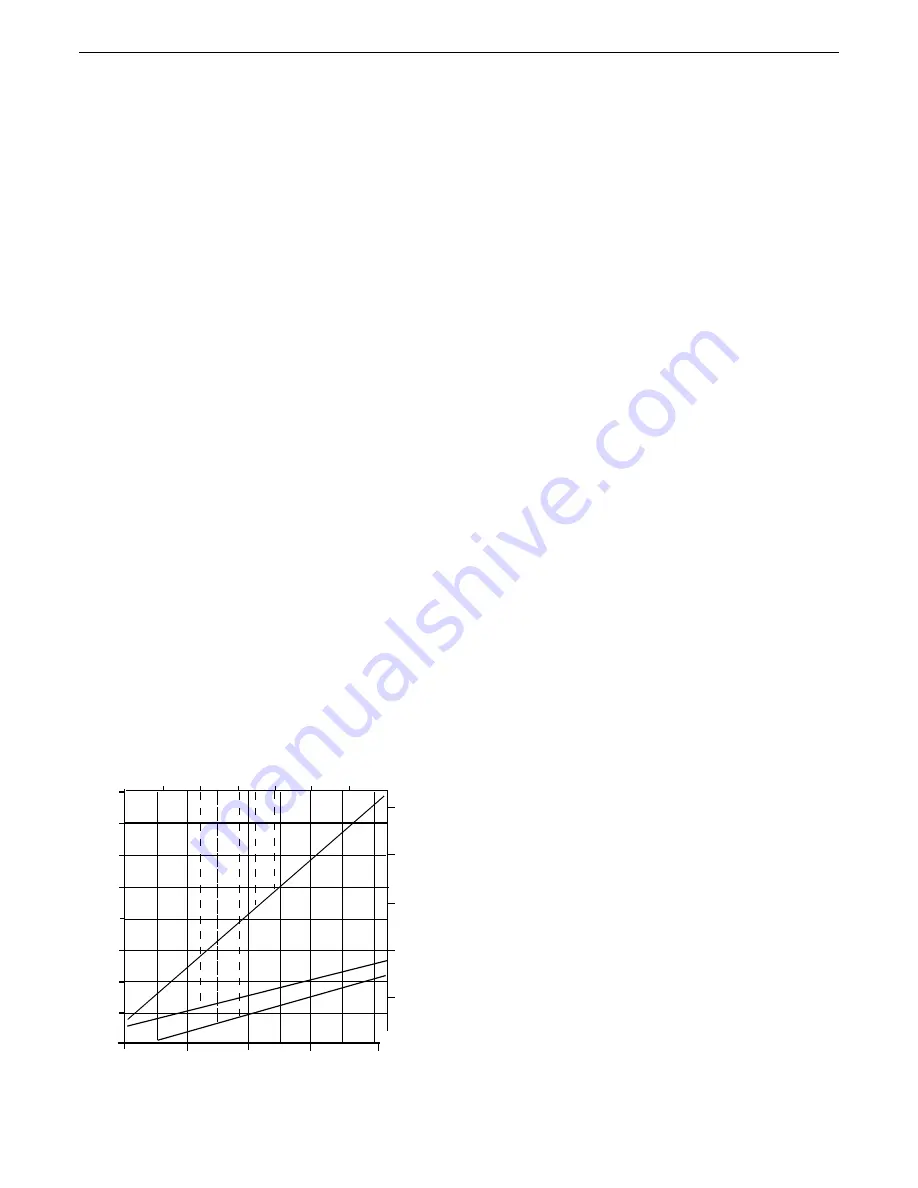

FLOW RATE (gals/hr)

PRESSURE

LOSS

(mbar)

FLOW RATE (l/min)

PRESSURE

LOSS

(ft.water)

140

100

60

20

10

20

30

40

50

1.0

2.

3.0

4.0

5.0

200

400

600

470 & 480

440

460

470

480

450 &

460

440

450

MEX

1886

Dotted lines indicate flow rates equivalent to a

temperature rise of 11

O

C (20

O

F)

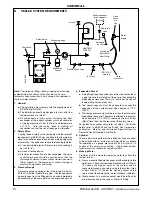

WATER CIRCULATION SYSTEM

The boiler must NOT be used for direct hot water supply. The

boiler is suitable for connection to pumped open vent central

heating systems, pumped central heating combined with

pumped or gravity indirect domestic hot water supply systems.

IMPORTANT

A minimum length of 2m of copper pipe MUST be fitted to both

flow and return connections from the boiler before connection to

any plastic piping. This applies to ALL types of installation.

The boiler is NOT suitable for gravity heating systems. The

hydraulic resistance of the boilers at

maximum output with 11

O

C

(20

O

F) temperature differentials are shown in the graph below.

Maximum boiler operating temperature should be 82

O

C (180

O

F).

The central heating system should be in accordance with

BS. 6798 and, in addition, for smallbore and microbore

systems, BS. 5449:1.

The domestic hot water system, if applicable, should be in

accordance with the relevant recommendations of BS. 5546.

Copper tubing to BS. 2871:1 is recommended for water carrying

pipework.

The hot water storage cylinder MUST be of the indirect type and

should preferably be manufactured of copper.

Single feed, indirect cylinders are not recommended and MUST

NOT be used on sealed systems.

The hot water cylinder and ancillary pipework not forming part of

the useful heating surface should be lagged to prevent heat loss

and any possible freezing - particularly where pipes run through

roof spaces and ventilated underfloor spaces.

IMPORTANT.

The boiler must be vented. If venting cannot be done via a flow

connection a separate vent MUST be fitted by the installer.

Draining taps MUST be located in accessible positions, which

permit the draining of the whole system - including the boiler and

hot water storage vessel. They should be at least

1/2" BSP

nominal size and be in accordance with BS. 2879.

If required, a drain tap (not supplied) may be fitted to an unused

bottom (1" BSP) tapping on the front of the boiler.