Classic

Slimline FF

-

Installation & Servicing

25

INSTALLATION

44 COMMISSIONING AND TESTING

A. ELECTRICAL INSTALLATION

1. Checks to ensure electrical safety should be carried out

by a competent person.

2. ALWAYS carry out preliminary electrical system checks,

i.e. earth continuity, polarity, resistance to earth and short

circuit using a suitable test meter.

WARNING. Whilst effecting the required gas soundness test and purging air from the gas installation,

open all windows and doors, extinguish naked lights and DO NOT SMOKE.

B. GAS INSTALLATION

1. The whole of the gas installation, including the meter, MUST

be inspected and tested for soundness, and purged in

accordance with the recommendations of BS. 6891.

In IE refer to I.S.813:2002.

2. Purging air from the gas installation may be expedited by

loosening the union on the gas service cock on the boiler

and purging until gas is detected.

3. Retighten the union and check for gas soundness.

45 INITIAL LIGHTING

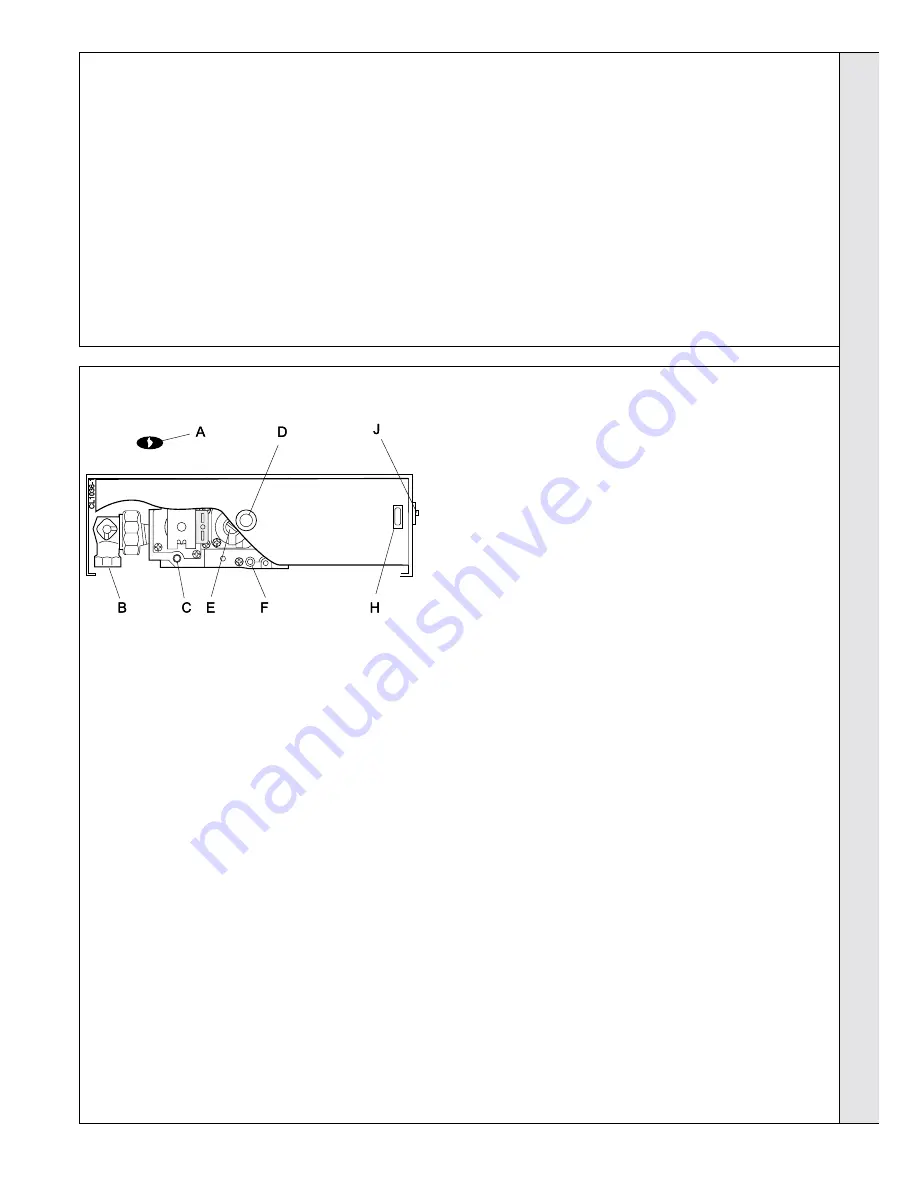

LEGEND

A Sightglass.

B Gas service cock.

C Inlet pressure test

point.

D Thermostat knob

E Main burner pressure adjuster.

F

Burner pressure test point.

H Boiler mains on/off switch.

J

Overheat thermostat reset button.

TO LIGHT THE BOILER

1. Check that all the drain cocks are closed, and any valves in

the flow and return are open.

2. Check that the gas service cock (B) is OPEN and the boiler

mains On/Off switch is OFF.

3. Fitting the Boiler Casing

The boiler casing must be refitted with the controls support

casing attached for alignment purposes. Lift the boiler

casing up to the boiler assembly, with the casing top

angled forward. Hook the top edge of the boiler casing into

the channel on the top of the boiler assembly. Swing the

bottom of the casing down and secure with the 2 captive

screws.

The casing must seat correctly and compress the sealing

strip to make an airtight joint.

Visually check the side seals but, if side clearances are

limited, then check that the top and bottom edges of the

casing are correctly located.

If the Sealed System Unit is fitted remove the unit casing in

order to inspect the top casing seal.

To gain access to the gas valve:

a. Remove the controls support casing. Release the

controls support front fixing screws 3 turns only. Remove

the pod by pulling it forward to disengage from the

keyhole slots.

b. Remove the control box securing screws and swing it

down into the servicing position. See diagram B.

4. Slacken the screw in the burner pressure test point (F) and

connect a gas pressure gauge via a flexible tube.

5. Swing the control box back into its working position.

6. Press the overheat thermostat reset button (J).

7. Switch the electricity supply ON and check that all external

controls are calling for heat.

8. Set the boiler thermostat knob (D) to position 6 and the

boiler Mains On/Off switch to ON. The fan will start. After

the fan has run for a few seconds the pilot solenoid valve

should open and the intermittent spark commence,

continuing until the pilot is established. The main burner

will then cross-light smoothly. If this sequence does not

occur, refer to the Fault Finding section.

9. Test for gas soundness around ALL boiler gas

components using leak detection fluid.

10. Operate the for 10 minutes to stabilise the burner

temperature.

11. The boiler is pre-set at the factory to its nominal rating. If

the burner pressure measured is incorrect it may be reset

using the following procedure. Refer to Table 2 (page 3):

a. Set the mains On/Off switch to OFF.

b. Switch the electricity supply OFF.

c. Swing the control box down into the servicing position.

d. Remove the main burner adjuster cover.

e. Turn the adjusting screw

clockwise to INCREASE the

pressure, or

anticlockwise to DECREASE the pressure.

f. Swing the control box back into its working position.

g. Switch the electricity supply ON.

h. Set the mains On/Off switch to ON and check the new

setting pressure.

12. If necessary repeat steps 12a to h until the required

pressure is achieved. Record this value in the Benchmark

log book.

13. Set the main On/Off switch to OFF.

14. Switch the electricity supply OFF.

15. Swing the control box down into the servicing position.

16. Refit the main burner pressure adjuster cover.

17. Remove the pressure gauge and tube. Retighten the

sealing screw in the pressure test point. Ensure a gas

tight seal is made.

The Benchmark Log Book or equivalent self certification should be completed and signed to demonstrate compliance with

Building Regulations.

INST

ALLA

TION

Summary of Contents for Classic FF 330

Page 1: ......

Page 39: ...Classic Slimline FF Installation Servicing 39 NOTES ...