28

Henrad SE FF

- Installation

INSTALLATION

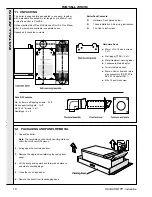

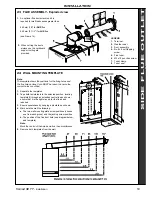

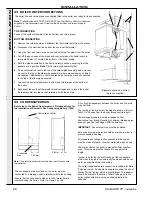

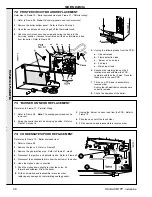

43 BOILER WATER CONNECTIONS

The boiler flow and return pipes are supplied fitted to the boiler and ready for top connection.

INST

ALLA

TION

Note.

For boiler sizes SE 30 FF to SE 60 FF use the 28mm x 22mm connectors

supplied in the hardware pack, to reduce the boiler flow and return pipes to

22mm.

TOP CONNECTION

Connect the system pipework to the boiler flow and return pipes.

BOTTOM CONNECTION

1. Remove the retaining pin and withdraw the thermostat phial from the pocket.

2. Disconnect the electrical leads from the overheat thermostat.

3. Undo the flow and return pipe unions and withdraw the pipes from the boiler.

4. Cut off the spun ends of the pipes and connect pipes of suitable length to

terminate 50mm (2") outside the bottom of the boiler casing.

5. Refit the pipe assemblies to the flow and return bosses, ensuring that the

gaskets are in position. Note.

Fit the return pipe assembly first.

6. Fit an

automatic air vent to the top of the return pipe assembly and a manual

air vent to the top of the flow pipe assembly (where pressures may at times

be negative). Alternatively, a combined feed and vent pipe may be connected

to the top of the flow pipe assembly.

7. Connect the system pipework to the flow and return pipes at the bottom of

the boiler.

8. Reconnect the overheat thermostat electrical leads and re-insert the boiler

thermostat phial into the pocket, retaining it with the split pin.

(Pipework shown as a dotted

line is not supplied)

3

4

6

1

2

Centre line of boiler

145 mm

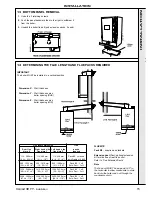

Condensate

drain

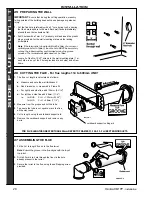

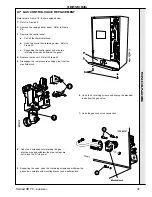

42 mm

Note.

The drain connection is located at the rear of the controls

compartment.

The condensate drain provided on the boiler must be

connected to a drainage point, preferably within the building.

Ensure that the condensate siphon is full of water before

commissioning the boiler. Refer to Frame 20 or 28.

Refer also to the British Gas document: 'Guidance Notes for

the Installation of Domestic Gas Condensing Boilers' (1989)

44 CONDENSATE DRAIN

A 'tun dish' arrangement between the boiler and the drain

may be fitted.

The routing of the drain must be made to allow a minimum

fall of 1 in 20 away from the boiler, throughout its length.

The drainage pipework must be arranged so that

obstruction (e.g. through freezing) of external drainage pipe

does not give rise to spillage within the dwelling.

IMPORTANT. Any external runs must be insulated.

Excessive external pipe runs should be avoided in order to

prevent possible freezing.

All pipework and fittings in the condensate drain system

must be made of plastic. No other materials may be used.

The drain outlet on the boiler is standard 22mm overflow

pipe. This size must not be reduced in any part of its

length.

In order to defer the onset of freezing of the condensate

drain when the pipe is run externally the pipe should be run

as far as possible within the building.

The boiler condensate drain connection is suitable for Bartol

'Polypipe' tubing. An adaptor is supplied to allow the use of

Marley 'Terrain' tubing, which is slightly larger. This adaptor

should be sealed to the Marley 'Terrain' tubing and to the

boiler condensate drain, using a suitable plastic tube

adhesive.

Summary of Contents for Henrad SE 30 FF

Page 1: ......