33

Henrad SE FF

- Installation

SERVICING

SER

VICING

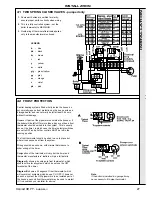

Note.

In order to assist fault finding, the control box printed circuit

board is fitted with three indicator lights which represent the

following boiler conditions. Refer to Frame 72.

LED 2

Lockout

LED 3

Fan on

LED 4

Mains electricity on

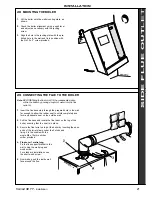

1. Isolate the electricity supply

2. Turn off the gas supply.

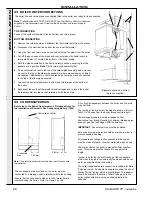

3. Remove the boiler front panel and sealing panel. Refer to

Frames 12 and 52.

IMPORTANT. When work is complete the sealing panel must

be correctly fitted, ensuring that a good seal is made.

WHEN REPLACING ANY

COMPONENT

REPLACEMENT OF COMPONENTS

and adjusted accordingly. Refer to Frame 47, 'Initial

Lighting' .

If the burner pressure is very low check the fan pressure.

Refer to Fault Finding Frame 82.

After any servicing, reference should be made to Table 2, page

3 (or the data badge), which quote details of the burner

pressures for the boiler models.

The burner pressure should be checked against these values

56 RE-ASSEMBLY

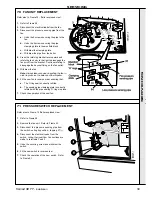

5. Reconnect the fan electrical leads.

6. Refit the boiler sealing panel.

IMPORTANT. Ensure the boiler sealing panel is correctly

fitted and that a good seal is made.

7. Refit the boiler front panel.

8. Turn on the gas supply at the gas service cock.

9. Reconnect the electrical supply.

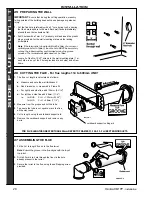

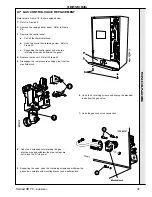

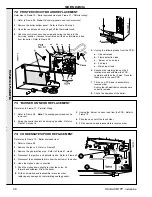

55 CLEANING THE HEAT EXCHANGER

1. Place a plastic sheet or similar beneath the boiler

and remove all visible loose deposits from the heat

exchanger fins, using a suitable brush.

2. Take care to clean debris from the ledge inside the

combustion chamber.

Note.

The pressure sensing pipes must be tested for gas soundness

THE BOILER MUST NOT BE OPERATED IF THE SEALING PANEL IS NOT FITTED.

57 BURNER PRESSURE CHECK

58 GENERAL

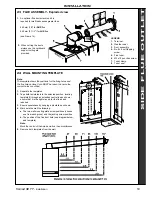

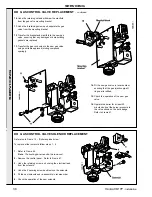

Reassemble the boiler in the following order:

1. Refit the burner, renewing any damaged or deteriorating

sealing gaskets.

2. Reconnect the 2 ignition leads and the detection lead.

3. Refit the fan, engaging it in the bayonet fixing and locating

it in the retaining bracket.

Ensure that the 'O' ring seal is in place.

4. Reconnect the pressure sensing pipe to the fan and secure

to the manifold block (together with the low pressure

sensing pipe), using the clamping plate.

Ensure that the 'O' ring seals are in place.

IMPORTANT.

Deposits are most effectively removed from the fins if they are

dry. Ensure this by running the pre-service checks with the

boiler thermostat set to maximum to avoid condensing

conditions.

Note.

Some aluminium oxide build-up on the heat exchanger fins is

quite usual with this type of condensing boiler. Though removal

is recommended annually, the heat exchanger MUST be

inspected and cleaned after a MAXIMUM of 2 years operation.

Summary of Contents for Henrad SE 30 FF

Page 1: ......