50

Henrad SE FF

- Installation

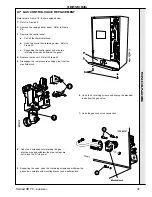

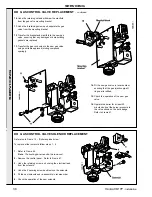

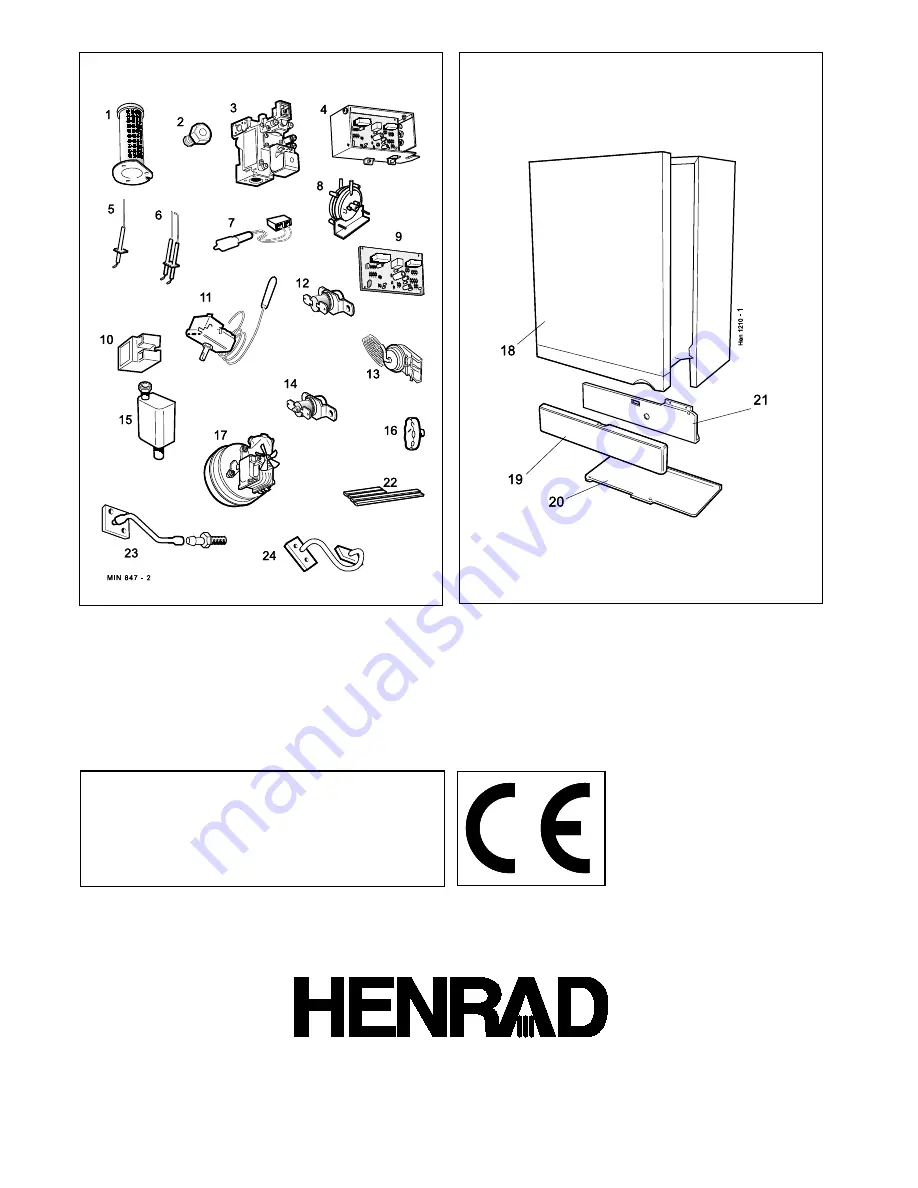

86 BOILER CASING ASSEMBLY

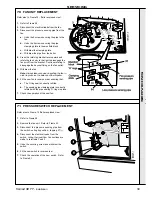

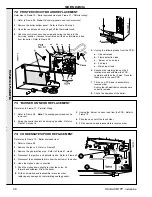

85 SHORT PARTS

SHORT LIST OF PARTS

Henrad Installer/Technical Helpline Tel: 01482 498663

Caradon Plumbing Limited

pursues a policy of continuing

improvement in the design and

performance of its products. The

right is therefore reserved to vary

specification without notice.

December 1999 UIN 153 960 A02

Technical Training

Caradon Plumbing Limited, P.O. Box 103, National Ave, Kingston upon Hull, HU5 4JN. Telephone: 01482

492 251 Fax: 01482 448 858. Registration No. London 322 137. Registered Office: National Avenue,

Kingston upon Hull, HU5 4JN.

A subsidiary of Caradon p.l.c

The Caradon Plumbing Limited Training Centre offers a

series of first class training courses for domestic,

commercial and industrial heating installers, engineers

and system specifiers. For details of courses please ring:

...................................................................... 01270 413 624

Summary of Contents for Henrad SE 30 FF

Page 1: ......