9

Henrad SE FF

- Installation

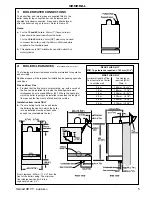

GENERAL

all dimensions in mm (in.)

3

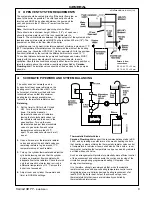

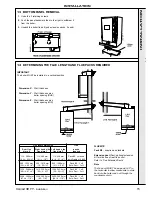

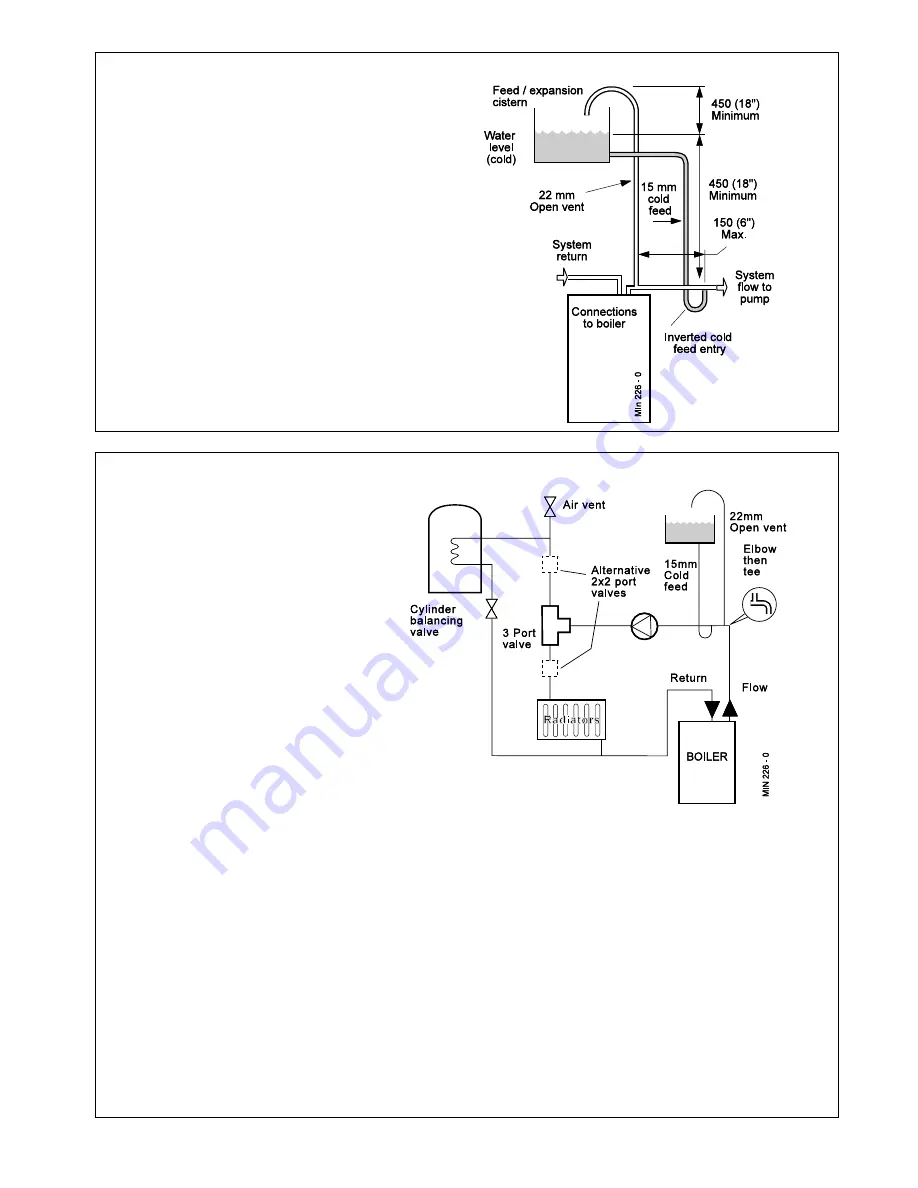

OPEN VENT SYSTEM REQUIREMENTS

4

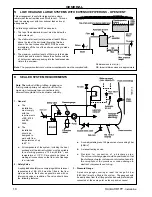

SCHEMATIC PIPEWORK AND SYSTEM BALANCING

The boiler does not normally need a

bypass but at least some radiators on the

heating circuit, of load at least 60% of the

boiler output, must be provided with twin

lockshield valves so that this minimum

heating load is always available (see

footnote re. thermostatic radiator valves).

Balancing

1. Set the timer to ON for both CH and

HW. Turn the cylinder thermostat

down. Close the manual or

thermostatic valves on all radiators,

leaving the twin lockshield valves (on

the radiators referred to above) in the

open position. Turn up the room

thermostat and adjust these lockshield

valves to give boiler flow and return

temperatures not more than 15°C

apart. These valves should now be left

as set.

Return & flow

connections

SE 30 - 60 FF = 22 mm

SE 70 - 80 FF = 28 mm

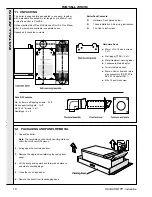

Thermostatic Radiator Valves

Caradon Plumbing Ltd. support the recommendations made in BS.

5449, and by leading manufacturers of domestic heating controls,

that heating systems utilising the thermostatic radiator valve control

of temperature in individual rooms shall also be fitted with a room

thermostat, controlling the temperature in a space served by radiators

not fitted with such a valve.

Such an arrangement will provide for potentially more efficient control

of the environment and will also avoid the continuous running of the

circulation pump during programmed heating ON periods - thus

saving electrical energy.

It is, therefore, strongly recommended that, when thermostatic

radiator valves are used, space heating temperature control over a

living/dining area or a hallway having a heating requirement of at

least 60% of the boiler heat output, is achieved using a room

thermostat whilst other rooms are individually controlled by

thermostatic radiator valves.

2. Open all manual or thermostatic radiator

valves and adjust the lockshield valves on

remaining radiators to give around 11°C

temperature drop at each radiator.

3. Turn up the cylinder thermostat and adjust the

cylinder balancing valve so that the cylinder

achieves a maximum flow consistent with

adequate flow to the radiators. Check that with

only the domestic hot water loop in circuit a

differential temperature of 15 °C across the

boiler is not exceeded.

4. Adjust room and cylinder thermostats and

timer to NORMAL settings.

The system should be vented directly off the boiler flow pipe, as

close to the boiler as possible. The cold feed entry should be

inverted and MUST be positioned between the pump and the

vent, and not more than 150mm (6") away from the vent

connection.

Note.

Combined feed and vent pipes may also be fitted.

There should be a minimum height, 450mm (18"), of open vent

above the cistern water level. If this is not possible refer to

Frame 5. The vertical distance between the highest point of the system and the

feed/expansion cistern water level MUST not be less than 450 mm (18"). The

pump must be fitted on the flow side of the boiler.

A suitable pump is a domestic circulator capable of providing a maximum 11°C

(20°F) temperature differential across the boiler with the whole of the heating

circuit open (e.g. Grundfos UPS 15/50, 15/60 or equivalent). With the minimum

flow circuit allowed by the controls the differential must not exceed 15 °C.

The vertical distance between the pump and feed/expansion cistern MUST

comply with the pump manufacturer's minimum requirements, to avoid

cavitation. Should these conditions not apply either lower the pump position or

raise the cistern above the minimum requirement specified by Caradon

Plumbing Ltd. The isolation valves should be fitted as close to the pump as

possible.

Summary of Contents for Henrad SE 30 FF

Page 1: ......