5

icos system condensing -

Installation and Servicing

GENERAL

SAFETY

Current Gas Safety (installation and use) regulations or rules

in force.

It is law that

all

gas appliances are installed and serviced by a

CORGI registered installer in accordance with the above

regulations. Failure to install appliances correctly could lead to

prosecution. It is in your own interest, and that of safety, to

ensure the law is complied with.

The installation of the boiler MUST also be in accordance with

the latest I.E.E (BS.7671) Wiring Regulations, local building

regulations, bye-laws of the local water authority, the building

regulations and the Building Standards (Scotland) and any

relevant requirements of the local authority.

Detailed recommendations are contained in the following

British Standard Codes of Practice:

BS. 5440:1

Flues (for gas appliances of rated input not

exceeding 70 kW).

BS. 5440:2

Ventilation (for gas appliances of rated input not

exceeding 70 kW).

BS. 5449

Forced circulation hot water systems.

BS. 5546

Installation of gas hot water supplies for

domestic purposes (2nd Family Gases)

BS. 6798

Installation of gas fired hot water boilers of rated

input not exceeding 60 kW.

BS. 6891

Low pressure installation pipes.

Health & Safety Document No. 635.

The Electricity at Work Regulations, 1989.

The manufacturer’s notes must NOT be taken, in any way, as

overriding statutory obligations.

IMPORTANT.

These appliances are CE certificated for safety

and performance. It is, therefore, important that no external

control devices, e.g. flue dampers, economisers etc., are

directly connected to these appliances unless covered by these

Installation and Servicing Instructions or as otherwise

recommended by

Caradon Ideal Limited

in writing. If in doubt

please enquire.

Any direct connection of a control device not approved by

Caradon Ideal Limited

could invalidate the certification and the

normal appliance warranty. It could also infringe the Gas Safety

Regulations and the above regulations.

SAFE HANDLING OF SUBSTANCES

Care should be taken when handling the boiler insulation

panels, which can cause irritation to the skin. No asbestos,

mercury or CFCs are included in any part of the boiler or its

manufacture.

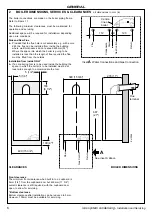

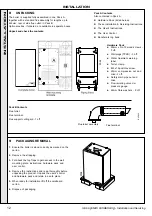

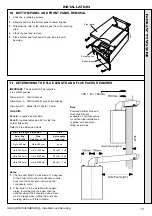

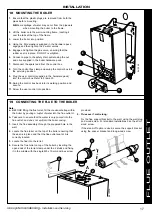

LOCATION OF BOILER AND FLUE OUTLET

The boiler must be installed on a flat and vertical wall, capable

of adequately supporting the weight of the boiler and any

ancillary equipment.

The boiler may be fitted on a combustible wall and insulation

between the wall and the boiler is not necessary, unless

required by the local authority.

For electrical safety reasons there must be no access available

from the back of the boiler.

The boiler must not be fitted outside.

Timber Framed Buildings

If the boiler is to be fitted in a timber framed building it should

be fitted in accordance with the Institute of Gas Engineering

document IGE/UP/7:1998.

Where installation will be in an unusual location, special

procedures may be necessary and BS.6798 gives detailed

guidance on this aspect.

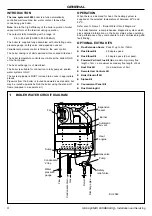

Compartment Installations

A compartment used to enclose the boiler should be designed

and constructed specially for this purpose.

An existing cupboard or compartment may be used, provided

that it is modified for the purpose.

In both cases, details of essential features of cupboard /

compartment design, including airing cupboard installation,

are to conform to the following:

z

BS. 6798 (No cupboard or ventilation is required - see air

supply for details).

z

The position selected for installation MUST allow adequate

space for servicing in front of the boiler.

z

For the minimum clearances required for safety and

subsequent service, see the wall mounting template and

Frame 2. In addition, sufficient space may be required to

allow lifting access to the wall mounting plate.

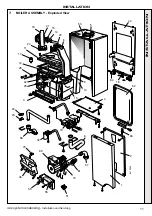

Summary of Contents for icos system m3080

Page 1: ......

Page 51: ...51 icos system condensing Installation and Servicing NOTES ...

Page 53: ......