53

sERVICINg

Ideal Logic Code Combi -

Installation and Servicing

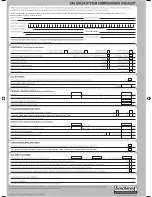

78 FaULT FINDINg ChaRT MaIN MENU

aLTERNaTINg ‘L’ and ‘1’

gO TO FRaME 79 -

FLOW TEMpERaTURE OVERhEaT LOCKOUT

aLTERNaTINg ‘L’ and ‘2’

aLTERNaTINg ‘L’ and ‘3’

aLTERNaTINg ‘L’ and ‘6’

aLTERNaTINg ‘F’ and ‘1’

aLTERNaTINg ‘F’ and ‘2’

aLTERNaTINg ‘F’ and ‘3’

aLTERNaTINg ‘F’ and ‘4’

aLTERNaTINg ‘F’ and ‘5’

aLTERNaTINg ‘F’ and ‘6’

aLTERNaTINg ‘F’ and ‘7’

aLTERNaTINg ‘F’ and ‘9’

aLTERNaTINg ‘F’ and ‘0’

aLTERNaTINg ‘c’ and ‘0’

gO TO FRaME 80 -

IgNITION LOCKOUT

gO TO FRaME 81 -

NO WaTER FLOW LOCKOUT

gO TO FRaME 82 -

FaLsE FLaME LOCKOUT

gO TO FRaME 83 -

LOW WaTER pREssURE

gO TO FRaME 84 -

FLaME LOss

gO TO FRaME 85 -

FaN FaULT

gO TO FRaME 86 -

FLOW ThERMIsTOR FaULT

gO TO FRaME 87 -

RETURN ThERMIsTOR FaULT

gO TO FRaME 88 -

OUTsIDE sENsOR FaULT

LOW MaINs VOLTagE -

CONTaCT ELECTRICITy pROVIDER

pCB FaULT -

**REpLaCE pCB aND REsET

gO TO FRaME 89 -

NO WaTER FLOW ThERMIsTOR FaULT

REsET BOILER

NO Ch BUT hW OK

NO hW BUT Ch OK

NO DIspLay

gO TO FRaME 91

gO TO FRaME 92

gO TO FRaME 93

**

If PCB replaced as a spare ensure that the BCC (boiler chip card - small plastic part) is fitted to the PCB otherwise replace PCB.

aLTERNaTINg ‘L’ and ‘5’

5 REsETs WIThIN 15 MINs -

TURN pOWER OFF aND ON

REsET pROCEDURE

- To reset boiler, turn mode knob to reset position and immediately turn knob back to required setting.

aLTERNaTINg ‘c’ and ‘2’

gO TO FRaME 90 -

BCC FaULT (BOILER ChIp CaRD)

Note that production boiler PCBs are factory pre-set to operate for boiler range and output, but when ordering Primary PCB as a

spare, an additional Boiler Chip Card (BCC) MUST also be purchased for your specific boiler range and output.

s

ER

VICIN

g

206279-1.indd 53

06/01/2011 09:10:49

Summary of Contents for LOGIC Code Combi 26

Page 2: ...2 Ideal Logic Code Combi Installation and Servicing ...

Page 61: ......