60

F

AUL

T FINDING F

AUL

T FINDING F

AUL

T FINDING F

AUL

T FINDING F

AUL

T FINDING

Installation and Servicing

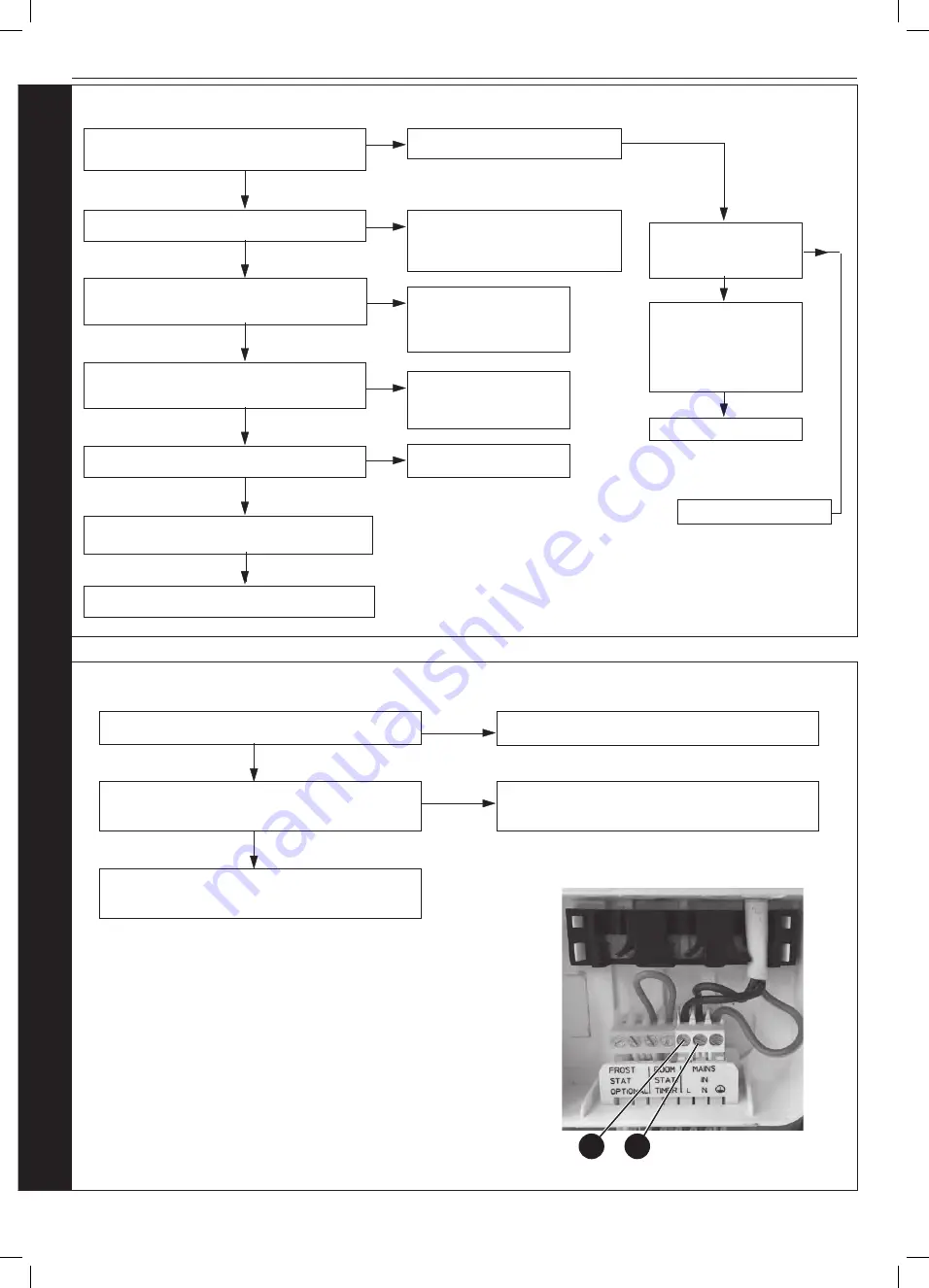

SECTION 4 - FAULT FINDING

4.12 NO HW BUT CH ON

4.13 NO DISPLAY

Is there 230Vac to the boiler at L and N?

YES

NO

Supply power to the boiler

Is the wiring from the terminal block to the PCB

connected securely?

YES

NO

Connect the wiring from the terminal block to the

PCB securely.

Replace the PCB?

Does the display shows a “Tap symbol” when

a tap is on?

NO

NO

YES

Are the flow rates correct as per Section 1.2.

Is the wiring between the PCB and the diverter

valve motor connected?

YES

YES

Check diverter head fully engaged and clip

secured onto waterset.

YES

Is diverter stuck in the CH position?

YES

Check and re-fit diverter valve actuator head.

Is Boiler DHW OK?

NO

Change diverter valve motor

NO

Adjust flow rates to achieve 35ºC

temp rise and check filter fitted in

turbine is not blocked with debris.

NO

Reconnect wiring or

replace wiring harness if

no continuity.

NO

Re-engage diverter

head and secure clip to

waterset

NO

Replace PCB

Is hot and cold pipework crossed?

Is the wiring connected

between PCB and DHW

sensor?

Remove the turbine, and

check for debris in the

turbine & filter. Replace

turbine if necessary. Is

DHW OK?

YES

NO

Re-connect wiring

NO

Replace turbine sensor

L

N

Summary of Contents for LOGIC COMBI ESP1 24

Page 4: ...4 Installation and Servicing...

Page 6: ...6 Installation and Servicing...

Page 62: ...62 Installation and Servicing SECTION 6 BENCHMARK COMMISSIONING...

Page 68: ...68 NOTES Installation and Servicing...

Page 69: ...69 NOTES Installation and Servicing...

Page 70: ...70 NOTES Installation and Servicing...