25

Installation and Servicing

FLUE OUTLET

SECTION 2 - INSTALLATION

2.9 CUTTING & SETTING THE FLUE LENGTH

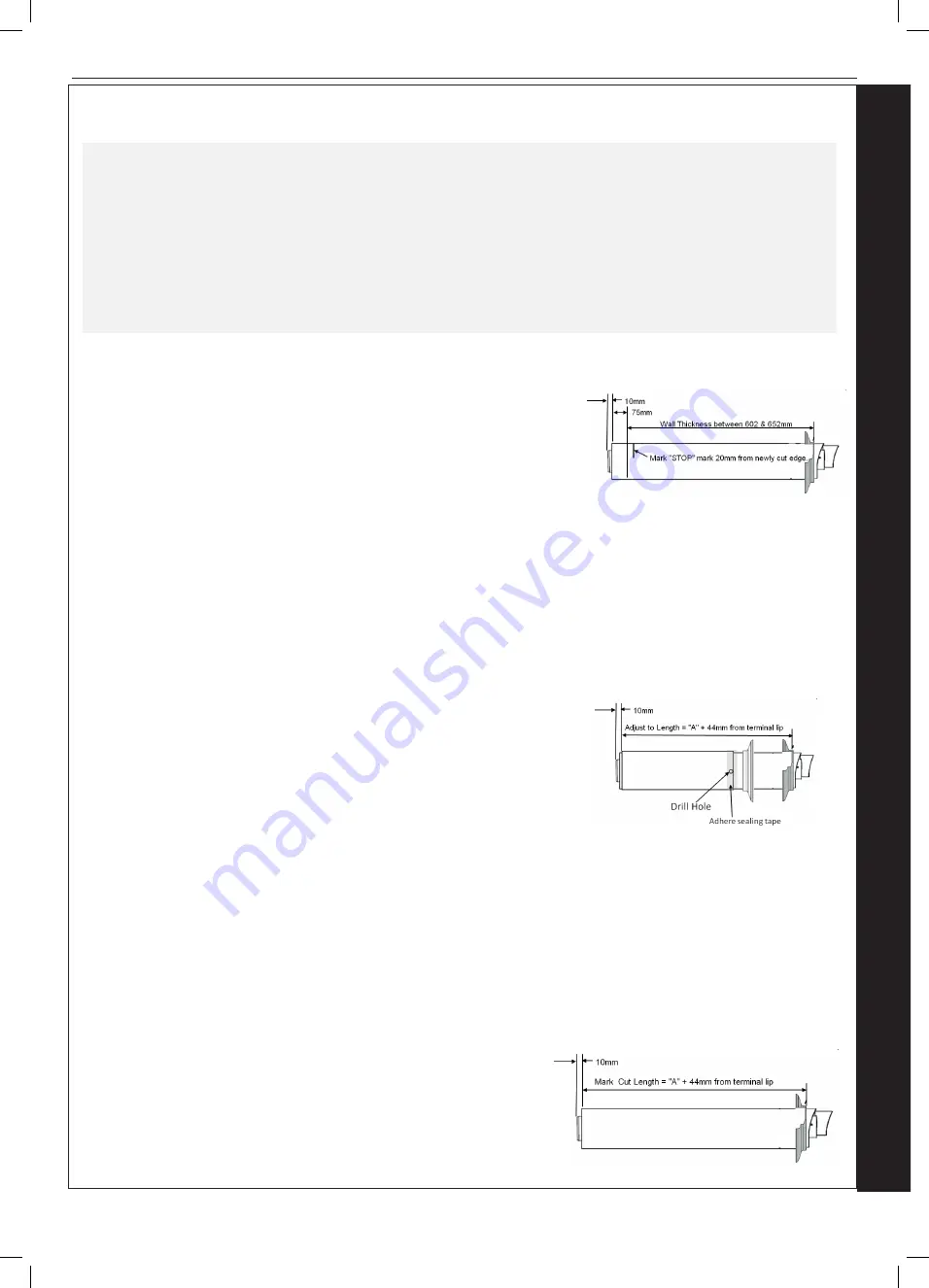

CUT 75MM OFF HORIZONTAL FLUE TERMINAL 1000MM LONG B PACK (TELESCOPIC)

1. Measure cut flue length (A+44mm). (If required telescopic length is not between

658 and 708 then proceed to “Setting Telescopic Flue B Pack”).

2. Remove telescopic end piece from the flue body and set aside.

3. Mark the circumference 75mm from the open end of the outer flue.

4. Cut along the 75mm mark cutting

only the outer flue

ensuring the cut is square.

5. Dress the cut end to make sure all burr is removed and the cut edge is in its

original shape.

6. Measure 20mm from the newly cut edge of the outer flue, place a mark at the top of the flue approximately 20mm wide &

write “stop” on the terminal side of the line.

7. Mark the inner tube 10mm longer than the outer tube around its circumference and cut following the mark to ensure it is cut

square

8. Remove all burrs and place a chamfer on the outer edge to aid assembly.

9. Re-assemble telescopic section.

SETTING TELESCOPIC FLUE B PACK

1. Measure the required flue length (A+44mm).

2. Measure from the outer terminal lip to end of outer flue. Pull apart flue until

desired length is achieved. ENSURE THE STOP MARK IS NOT VISIBLE,

IF IT IS, THE FLUE IS TOO SHORT AND SHOULD NOT BE USED.

3. Check that both flue seams are at the top and the outlet terminal is upper

most.

4. Drill a 3.5mm hole through one of the 2 outer side holes in the outer flue

section into the inserted outer flue (as shown). Take care not to pierce the

inner plastic flue. Fit screw provided.

5. Seal the joint on the outer air duct with the tape provided.

6. Fit internal and external wall seals (see installing flue)

CUTTING HORIZONTAL FLUE TERMINAL (600MM LONG) B PACK

1.

Measure the required cut flue length (A+44mm). If inside the dimensions

shown “1 Piece 600mm” proceed.

2. Measure from the outer terminal lip to end of outer flue. Mark the

required cut length (A+44) around the circumference of the outer flue and

cut following the mark to ensure it is cut square.

3. Dress the cut end to make sure all burrs are removed and the cut edge is

in its original shape.

4. Mark the inner tube 10mm longer than the outer tube around its

circumference and cut following the mark to ensure it is cut square.

5. Remove all burrs and place a light chamfer on the outer edge to aid

assembly.

TELESCOPIC FLUES

TELESCOPIC FLUE B PACK

SHOULD ONLY BE ADJUSTED FOR USE WITHIN ITS SPECIFIED RANGE AND MUST NOT

BE CUT

HORIZONTAL FLUE TERMINAL (1000MM LONG) B PACK (TELESCOPIC)

MUST ONLY BE CUT IF REQUIRED FLUE

LENGTHS ARE BETWEEN

602

&

652MM

. THIS WILL REQUIRE 75MM TO BE CUT OFF THE TERMINAL END OF THE

1000MM TELESCOPIC FLUE.

ALL OTHER LENGTHS OBTAINED USING “D” PACK EXTENSIONS IN FLUE LENGTH TABLE 1, COLUMN “HORIZONTAL

FLUE TERMINAL (1000MM LONG) B PACK CUT 75MM” (TELESCOPIC) SHOULD HAVE THE 75MM CUT OFF THE “D”

PACK EXTENSION AND NOT TELESCOPIC FLUE

Summary of Contents for LOGIC MAX HEAT H 18

Page 4: ...4 Installation and Servicing...

Page 6: ...6 Installation and Servicing...

Page 61: ...61 NOTES Installation and Servicing...

Page 62: ...62 Installation and Servicing SECTION 5 SPARE PARTS...

Page 68: ...68 NOTES Installation and Servicing...