30

Mexico Super RS440 - RS470 -

Installation & Servicing

SERVICING

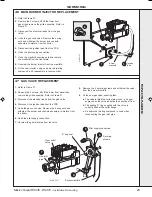

48 PRINTED CIRCUIT BOARD (PCB) REPLACEMENT

1.

Refer to Frame 37.

2.

Remove the 2 screws and lift off the

lower front panel. Refer to Frame 31.

3.

Undo the PCB cover fixing screw and

remove the cover.

4.

Remove the HT lead from the PCB

5.

Remove the 6 push-in connectors

from the PCB.

6.

Compress the barbs on the PCB

stand-offs to release the PCB from

the box

7.

Fit the new PCB and reassemble in

reverse order.

8.

Refit the boiler casing.

9.

Check the operation of the boiler.

MEX 2325

6

4

3

5

200941-1.p65

3/3/2004, 10:25 AM

30