INSTALLATION

mini HE

--- Installation & Servicing

16

11 FITTING THE FLUE SYSTEM

The minimum and maximum equivalent length for

co---axial pipes ø 60---100 and ø 80---125 mm are given in

Table 6.

The minimum and maximum equivalent length for ø 80

mm twin pipe systems are given inTable 7.

For roof flue systems having a flue length greater than

3m and all twin pipe systems, a condensate drain kit

must be fitted at the lowest point in the system. See the

list of optional extras (frame 9) for available drain kits.

Refer to the assembly instructions contained within the

chosen flue kit packaging for the correct assembly and

installation.

The horizontal sections of flue pipes must have a slope

not less than 1.5 deg. (25 mm per metre) towards the

boiler.

In the flue kit of pack B the flue pipe is angled within the air

duct therefore the air duct must be horizontally installed.

In the case that one or more extensions need to be used they

must be adequately supported so that there is no sag in the

flue pipe and a minimum fall of 1.5 deg. (25 mm per metre)

over the whole length towards the boiler is ensured.

Table 6

Minimum

Maximum

Co---axial 60---100 0.3 (11.8”)

2.7 (8’ 10”)

Co---axial 80---125 0.5 (19.7”)

8.5 (27’ 10”)

Co---axial Flue kits.

Horizontal.

For calculation of total flue length, the distance MUST be

measured from the centreline of the concentric elbow to the

end of the terminal.

Vertical outlet

For calculation of total flue length, the distance MUST be

measured from the centreline of the outlet connector at the

boiler top panel to the end of the terminal grille.

For each additional 45° and 90° flue bend used, the

maximum permissible length of flue system must be reduced

by 1 m or 1,5 m respectively.

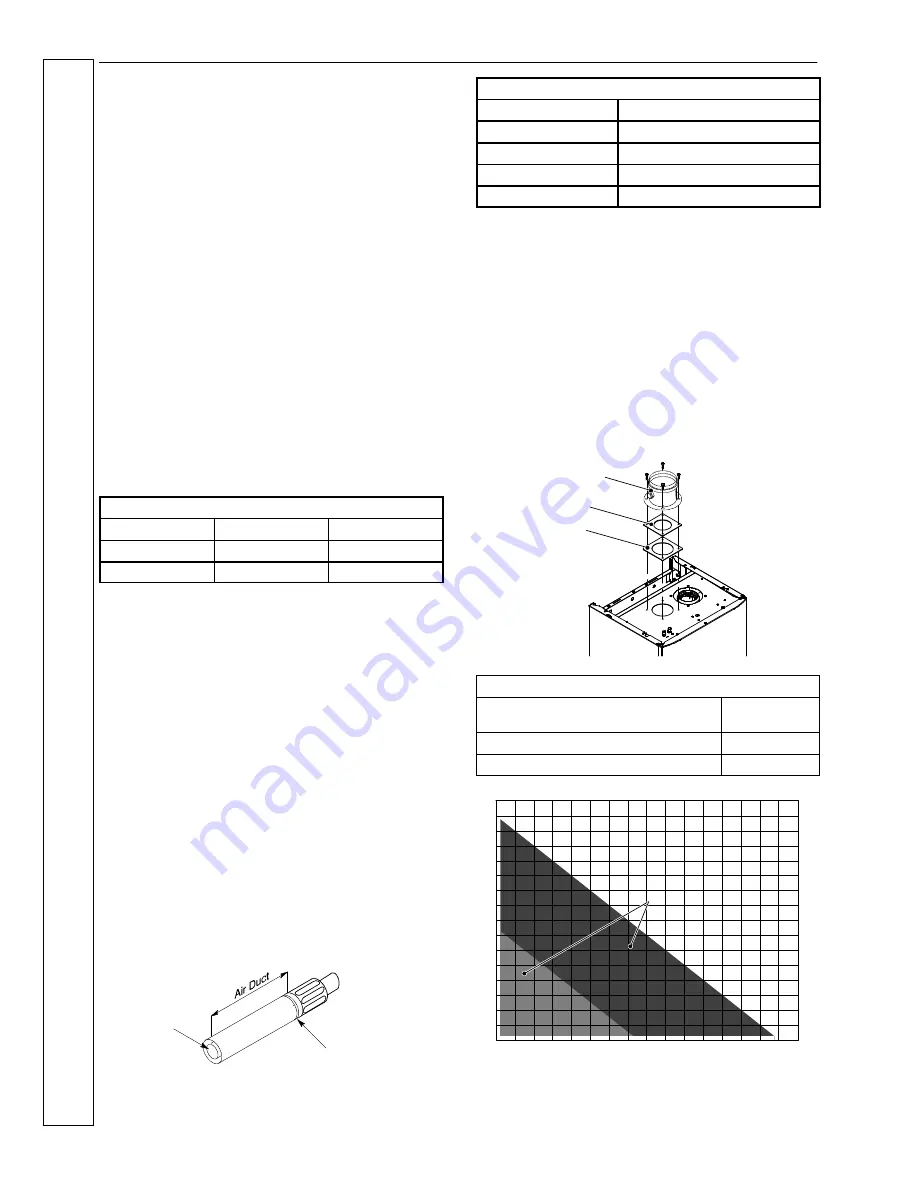

Cutting lengths of flue and air ducts

Measure the wall thickness and, when using a side outlet, the

gap between the inner wall and the boiler side casing.

Use the following chart to calculate the cutting length of air

duct.

Mark the air duct making reference on the groove.

Cut the flue duct at the same level of the air duct edge.

Groove

Cut this end

Horizontal Concentric

Air duct

Rear Outlet

Wall thi 125 mm

Rear Stand---off Wall thi 160 mm

Side Outlet --- RH

Wall thi Gap +62 mm

Side Outlet --- LH

Wall thi Gap +208 mm

Twin pipe flue kits

For calculation of total flue length, the distance MUST be

measured from the centreline of the flue duct/air duct

connection to the end of the flue outlet grille/air inlet duct.

For each additional 45° M&F and 90° M&F flue bend used,

the maximum permissible length of flue system must be

reduced by 0,9m or 1,65m respectively.

Two restrictors with different sizes are supplied with the twin

pipe kit and have to be installed between the boiler and the

air intake adapter as indicated in the following picture.

The restrictor to be used and the lengths of allowable

equivalent flue outlet / air inlet ducts are indicated in Table 7

and in the following graph.

The restrictor size is marked on its body.

Air intake adapter

Restrictor

Gasket

Table 7

Equivalent pipe length

(air duct + flue duct)

Restrictor

Between 1 (39“) and 15 m (49’ 2”)

ø 50 mm

More than 15 m (49’ 2”) up to 30 m (98’ 5”) ø 55 mm

0

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

0

2

4

6

8

10 12 14 16 18 20 22 24 26 28 30 32

Restrictor

50 mm

Allowed values

Flue exhaust ”a”

Air intake ”b”

Restrictor

55 mm

IN

S

T

A

L

L

A

T

IO

N