The complete installation MUST be tested for gas tightness

and purged as described, for the majority of installations the

appropriate standard is IGEM/UP/1B [23], but alternatively

IGEM/UP/1 [21] or IGEM/UP/1A [22], as appropriate, can be

utilized.

1.10 WATER CIRCULATION SYSTEM

IMPORTANT:

A minimum length of 1 metre of copper

pipe MUST be fitted to both flow and return connections from

the boiler before connection to any plastic piping.

The central heating system should be in accordance with

BS6798 and, in addition, for smallbore and microbore systems,

BS EN 12828:2012+A1:2014.

Water treatment is covered later in these instructions.

Refer to Section

1.18

1.11 BOILER CONTROLS

Install CH controls to ensure that the boiler has no demand

when there is no requirement from the system.

Heating systems with TRVs in individual rooms must include a

thermostat to control the temperature in rooms without TRVs.

At least 10% of the minimum boiler heat output should be

achieved using a room thermostat. A bypass circuit with an

automatic bypass valve must be fitted to systems with TRVs or

two-port valves on all the radiators to ensure water flow.

1.12 ELECTRICAL SUPPLY

WARNING:

This appliance must be earthed.

Wiring external to the appliance MUST be in accordance with

the current I.E.E. (BS7671) Wiring Regulations and any local

regulations which apply.

For IE, reference should be made to the current ETCI rules for

electrical installations.

The mains supply to the boiler and system wiring centre

shall be through one common fused double pole isolator and

for new heating systems, and where practical replacement

installations, the isolator shall be situated adjacent to the

appliance.

1.13 CONDENSATE DRAIN

The condensate drain provided must be connected to the

drainage point on site. All condensate drainage pipework and

fittings must be made of plastic.

IMPORTANT:

The condensate drain pipework should

be installed in accordance with BS6798.

The drain outlet on the boiler is sized for standard 21.5 mm

overflow pipe. It is a universal fitting to allow use of different

brands of pipework.

Refer to Section

2.16

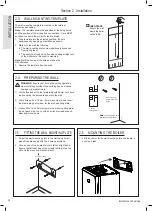

Compartment Installations

A boiler installed in a compartment does not require ventilation.

However, a boiler installed in a compartment must provide

adequate clearances for servicing. The compartment should

also be fitted with a suitable label in accordance with current

standards.

Refer to Section

1.14

1.8 AIR SUPPLY

It is not necessary to have an air vent in the room or internal

space where the boiler is installed.

1.9 GAS SUPPLY

Consult the local gas supplier to establish an adequate supply

of gas. Do not use existing service pipes without consulting the

local gas supplier.

The gas supply must be governed with a meter.

A gas meter can only be connected by the local gas supplier or

by a Gas Safe Registered Engineer or in IE a Registered Gas

Installer.

An existing meter should be checked, preferably by the gas

supplier, to ensure that the meter is adequate to deal with the

required gas supply rate.

It is the responsibility of the Gas Installer to size the gas

installation pipework in accordance with BS6891.

Whilst the principle of the 1:1 gas valve ensures the Keston

range is able to deliver it is full output at inlet pressures as low

as 14 mb, other gas appliances in the property may not be as

tolerant. When operating pressures are found to be below the

minimum meter outlet of 19 mb these should be checked to

ensure this is adequate for correct and safe operation.

Allowing for the acceptable pressure loss of 1mb across the

installation pipework, it can be assumed that a minimum

permitted operating pressure of 18mb will be delivered to the

inlet of the appliance.

(Reference BS6400-1 Clause 6.2 Pressure Absorption).

The external gas cock could further reduce the operating

pressure when measured at its test point. The pressure drop

is relative to the heat input to the boiler (kW), refer to graph

below.

Gas Cock Pressure Drop

Heat Input to Boiler (kW)

Pressure Drop (mbar)

0 5 10 15 20 25 30 35 40

1.4

1.2

1

0.8

0.6

0.4

0.2

0

IMPORTANT:

Ensure all gas valve connections are gas

tight with a gas soundness check up to the gas control valve.

Installation pipes must be fitted in accordance with BS6891.

10

Installation and Servicing

Section 1 - General