23

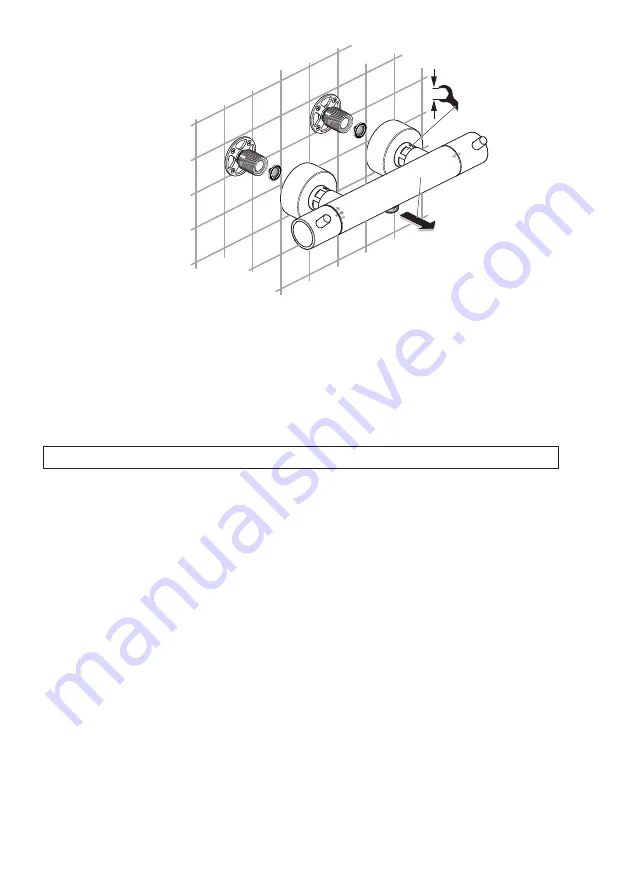

Method for demounting mixer:

1.

Observe disassembling sequence, as detailed in

section 14, steps 1 & 2.

2.

Remove the overhead shower assembly, if fitted (A7594AA only).

3.

Undo the two coupling nuts located at the rear of the mixer (see fig above). Take care not to lose the

two sealing /strainer washers.

4.

Lift the mixer body off from the wall mount brackets, by gently pulling away as shown.

5.

The mixer body can be further dismantled for cleaning protocols. Do not leave the wall mount

brackets or deck legs uncovered for long periods, protect from environmental contamination.

6.

To refit the mixer body; reverse this procedure. Tighten the nuts at the rear of the mixer securely.

NOTE: Procedure is the same for the deck mount mixer.

Disinfection method

Disinfection by full immersion in an appropriate bactericidal solution is recommended for this assembly.

Prior to immersion, the mixer body should be clean and dismantled to a level that prevents air locking.

The level of dismantling should be established as a result of practice and will be largely dependent upon

the water quality and service life. As a minimum we recommend removal both handles, thermostatic

cartridge & flow-control (or diverter) cartridge. Cleaning the cartridge strainer screens is important. All

components can be immersed together unassembled.

Disinfected mixers should be promptly replaced or stored using an appropriate method until required.

Disinfection frequency

The frequency of such disinfection actions will be derived from regular sampling carried out under the

regime of the Responsible Person (Water). We would not expect to need greater than 6 monthly fre-

quencies, hopefully considerably less.

The need for excessive use of this procedure would be indicative of the need for some root cause analy-

sis as there could be some system or behavioural problems that need addressing.

Recommended Disinfection Solutions

For immersion we recommend the use of a 70% Ethanol solution for 10 minutes.

NB: counter intuitively,

greater than recommended concentrations are less effective

not more effec

-

tive; take care to get the recommended concentration in line with the manufactures recommendation.

DO NOT USE SOLUTIONS CONTAINING AMMONIA.

30

Avoid damaging the inlet seals. See sections 21 & 22 for replacement strainer washers.