Before commencing, decide on which installation method to adopt from the two detailed below. Mark the

wall at the desired location for the valve-box. Decide on preferred mounting option (see 4.3). Note: before

mounting, it may be easier to fit pipe connectors to the valve-box (see 5.1).

CAVITY METHOD requires the installer to chase-out the brick-work to the required depth. Then mount the

valve-box & pipe-work into this cavity. The cavity can then be closed-off for example with plaster board. Cut

large hole in the covering plaster board to suit the valve-box diameter (see below).

FALSE-PARTITION METHOD requires the installer to mount the valve-box directly

onto the wall, then build a false partition or use a panelling system in front of the wall to conceal the valve-box

& pipe-work. The false wall can be just local to the valve area.

Cut large hole in the covering panel to suit the valve-box diameter (see below).

Ø133

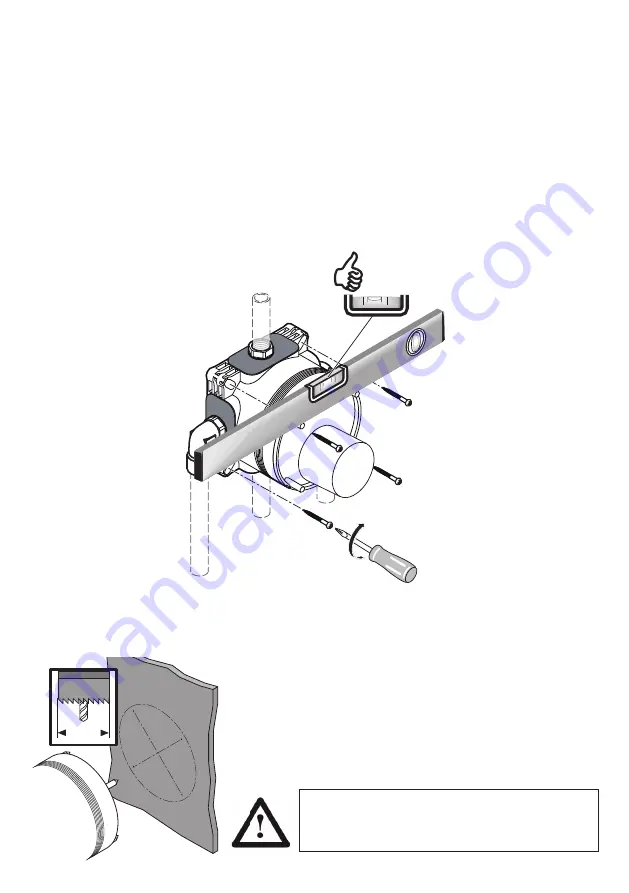

Check level & valve-box orientation (see 4.5). Confirm valve-box is projecting correctly from the wall; such

that the finished wall will fall between the depth markers (see 4.2).

For both methods, drill at lease 4 fixing holes in the wall & fit suitable wall plugs for screw type being used.

Ensure valve-box is securely attached to the wall.

Use suitable sup

-

porting washers

under the screw

heads

The large hole to be cut in the panel or plaster board

should be Ø133mm (5.1/4”), which permits some clearance

around the valve-box diameter (Ø129mm)

ENSURE THIS HOLE IS ADEQUTELY SEALED. USE THE

FLEECE MAT SUPPLIED WHEN TILING OR USE A SUIT

-

ABLE SEALANT FOR PANEL INSTALLATIONS.

WARNING:

Cavity should only be closed off when all

pipe-work has been checked for leaks.

Remember

isolating valves must be installed in an

easily accessible location

5.4 Mounting valve-box into a solid wall

17