19

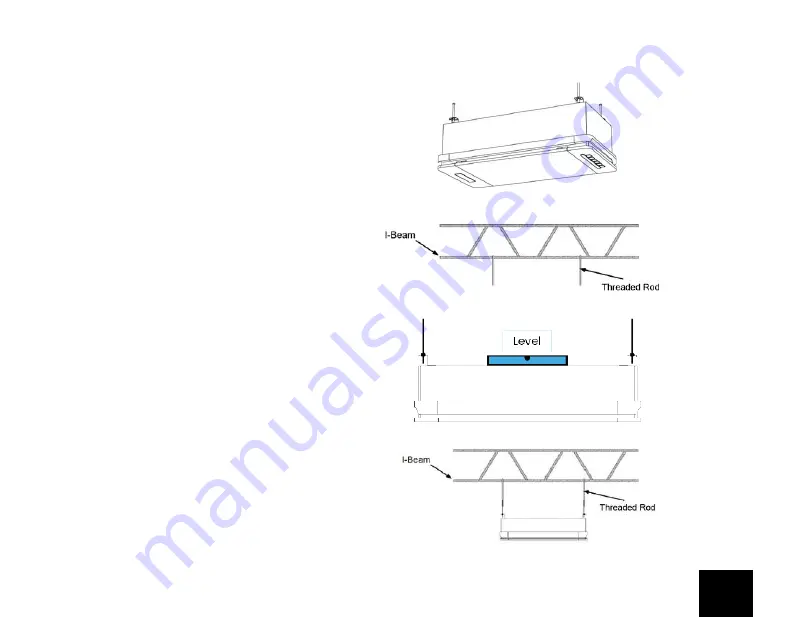

3. Load all the four cabinet hangers into

nut 3.

4. Secure the threaded rod to the I-

Beam as shown.

5. Using a level in both directions,

adjust nut 3 and nut 4 to ensure the

machine is leveled horizontally. Finally

tighten nuts 3 and 4 to fix the machine

in place, connect the power to

complete the installation.

SCA14000 Cobalt Installation Guide