The chain wildcats

# 8

are driven by friction. The release wheel

#1

engages

and disengages the wildcats.

1.)

LOWERING THE ANCHOR ELECTRICALLY

– loosen the release

wheel

#1

on the side not being used and tighten the wheel on the side to be

used. It is necessary to secure the chain on the side not being used with a

chain stopper. Step on the down footswitch or engage the down button on the

remote control. Reverse this process to lower the 2nd anchor.

2.)

LOWERING THE ANCHOR – FREE FALL

– Caution must be used

when using the free fall feature. The operator must keep away from the outgo-

ing chain at all times. Disengage the clutch by turning the release wheel

#1

counter-clockwise. Release the chain stopper. The speed of the outgoing

chain can be controlled with the release wheel.

After the anchor is set

– set

the chain stopper. Do NOT allow the vessel to sit at anchor with the strain on

the anchor windlass. A chain stopper or suitable device must be used.

3.)

HOISTING THE ANCHOR

– Before hoisting the anchor check the

other wildcat to see if it is engaged or disengaged. See above. Engage the

wildcat by turning the release wheel

#1

clockwise. Push the up switch. If the

anchor is nestled in a hawse pipe, “inch” or “jog” the windlass the last few

feet.

Severe damage may result otherwise.

4.)

MANUAL OPERATION

- Insert the manual bar into the slot located in

the ratchet ring

#11

and pump back and forth.

5.)

HYDRAULIC SETTINGS

– The windlass is designed to run at 5.5

GPM at 1500 PSI.

5

CAPSTAN (line handling):

The capstan is directly keyed to the main shaft

and will always turn when the windlass is engaged. Wrap 3 or 4 turns around

the capstan going over the top of the capstan in a clock wise direction, and

keeping a small amount of tension on the line, step on the UP switch. If the

line slips apply more tension or add another wrap. The capstan may be used

independently of the wildcat by loosening the release wheel # 17 to disen-

gage the wildcat # 5.

CAUTION

: Do not wrap chain around the capstan.

WILDCAT (chain handling):

The chain wildcat #5 is driven by friction. The

release wheel #17 engages and disengages the wildcat. The chain may be

lowered electrically by using the down switch or by using the

FREE FALL

–

Caution must be used when using the free fall feature. The operator must

keep away from the outgoing chain at all times. Disengage the clutch by turn-

ing the release wheel #17 counter-clockwise. The speed of the outgoing chain

can be controlled with the release wheel.

After the anchor is set

– set the

chain stopper. Do NOT allow the vessel to sit at anchor with the strain on the

anchor windlass. A chain stopper must be used.

HOISTING THE ANCHOR with all chain

– Engage the wildcat by turning

the release wheel #17 clockwise. Push the up switch. If the anchor is nestled

in a hawse pipe, “inch” or “jog” the windlass the last few feet.

Severe damage

may result otherwise.

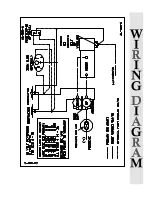

CIRCUIT BREAKER—

The windlass electrical system must be isolated and

protected. The breaker should be left OFF when the windlass is not in use.

This will prevent accidental activation. If the breaker trips from electrical

overload it can be reset immediately.

CAUTION

: Do not allow the windlass to operate without a load for any

long length of time as the motor is a series wound type that will heat up and

damage can result. It is not necessary to pause while pulling up the anchor as

the motor can run for several minutes at a time.