MAINTENANCE SCHEDULE

Every six months:

Gear case

: check the oil level by removing the pipe plug fitting in the

front of the windlass. The oil should be up to this level. Add

90WT

gear oil if necessary.

Once a year:

Wildcat:

remove cotter pin #1, washer #2, the release wheel

#

17, the

friction plate #18, chain stripper #19 and wildcat #5. Clean and

grease the bore of the wildcat and friction plate . And the hubs of t h e

inside & outside friction plates #18 & 7. The friction plate #18 should

move in & out on the shaft easily.

Do not get grease on either of the

friction discs #4.

Every 2 years:

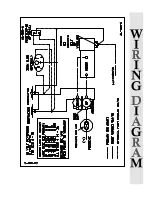

Electrical components:

inspect the electrical connectors and spray

with electrical cleaner. Inspect for wear. Inspect rubber covers on the

footswitches and replace as necessary.

Gear case:

change the oil in the gear case. There is no drain plug on the

Model CWM. Use a small oil changing pump to remove the old oil.

Fill to the level of the oil plug with

90WT

gear oil. Do not overfill.

6