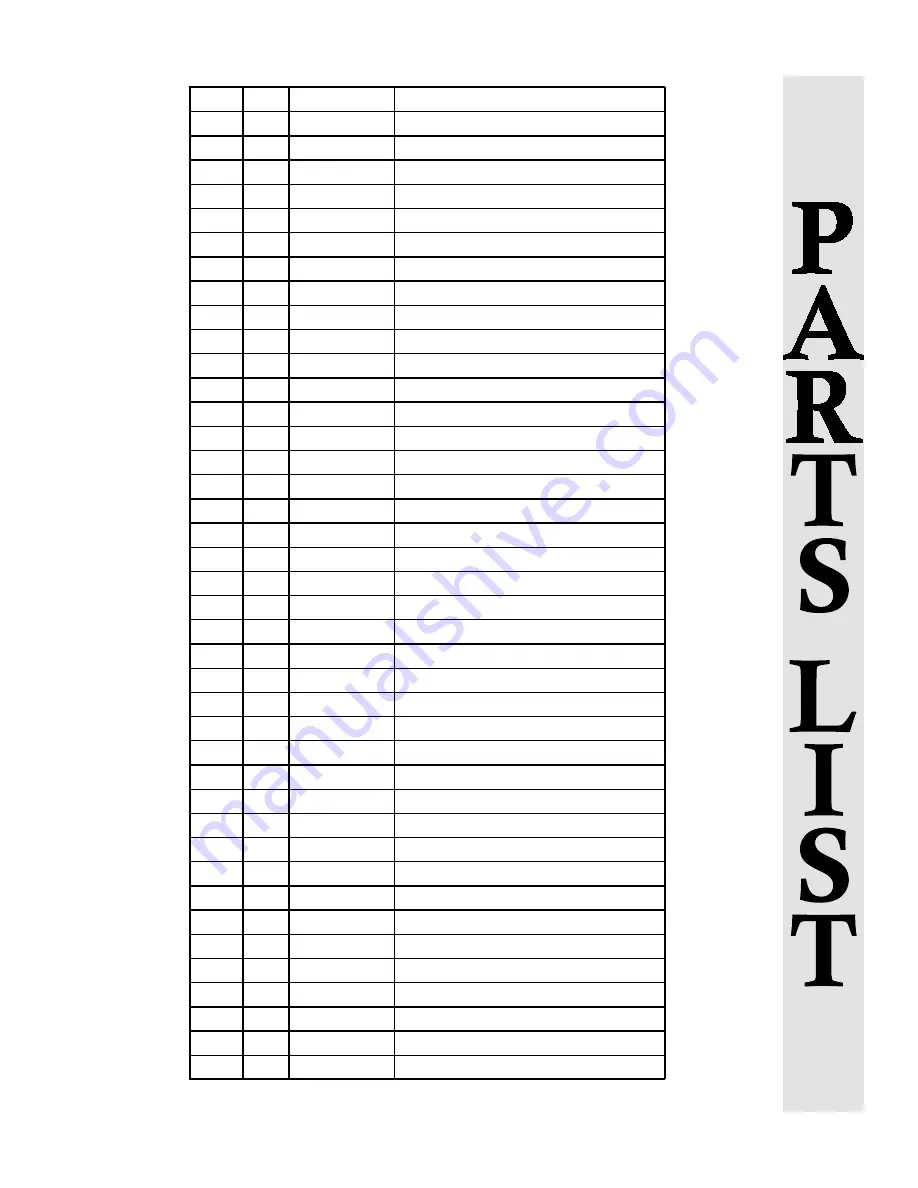

8

ITEM QTY

PART #

DESCRIPTION

1

1

CP-40

COTTER PIN

2

1

RW-35

WASHER

3

1

CK-35

WILDCAT KEY

4

2

CWM-9

FRICTION DISC

5

1

CWM-10

WILDCAT

6

2

DP-35

DRIVE PIN

7

1

CWM-8

INNER FRICTION PLATE

8

1

AM-16

SHORT BEARING CAP

9

2

OS-35

OIL SEAL

10

1

AM-12

WORM GEAR

11

1

WK-35

WORM KEY

12

1

CAM-1

GEAR CASE

13

1

AM-16A

LONG BEARING CAP

14

1

CS-10

CAPSTAN SCREW

15

1

CW-10

CAPSTAN WASHER

16

1

CWA-2

CAPSTAN

17

1

CHWS0-8

RELEASE WHEEL

18

1

CWM-15

OUTTER FRICTION PLATE

19

1

CWM-13A

CHAIN STRIPPER

20

9

FA-35

HEX BOLTS

21

2

SS-35

SET SCREWS

22

1

A-20

MOTOR WORM

23

1

CWM-5

MAIN SHAFT

24

1

CP-35

COTTER PIN

25

1

GT-3

THRUST BEARING

26

1

AM-3

END BELL

27

1

RN-35

RETAINING NUT

28

1

WK-09

MOTOR WORM KEY

29

1

SO-12

SOLENOID non-reversing

29

1

SO-12 REV

SOLENOID reversing

30

1

FSB

FOOTSWITCH

31

1

MM-350-12 MOTOR W/OUT GEAR & BRG

31

1 MMC-350-12

MOTOR W/ GEAR & BRG

32

1

MM-87

OIL SEAL

33

1

FSB-1B

RUBBER COVER

34

1

FSA-3

MOUNTING RING

35

2

FSA-7

ELEMEMENT RETAINING NUT

36

1

ELM-DC

SWITCH ELEMENT

37

1

FSA-2

MOUNTING PLATE

38

6

FSA-6SS

MOUNTIING SCREWS