52

EVOMAX

-

Installation & Servicing

fAuLt fInDInG

f

A

u

L

t f

In

DI

n

G

f

A

u

L

t f

In

DI

n

G

f

A

u

L

t f

In

DI

n

G

f

A

u

L

t f

In

DI

n

G

f

A

u

L

t f

In

DI

n

G

f

A

u

L

t f

In

DI

n

G

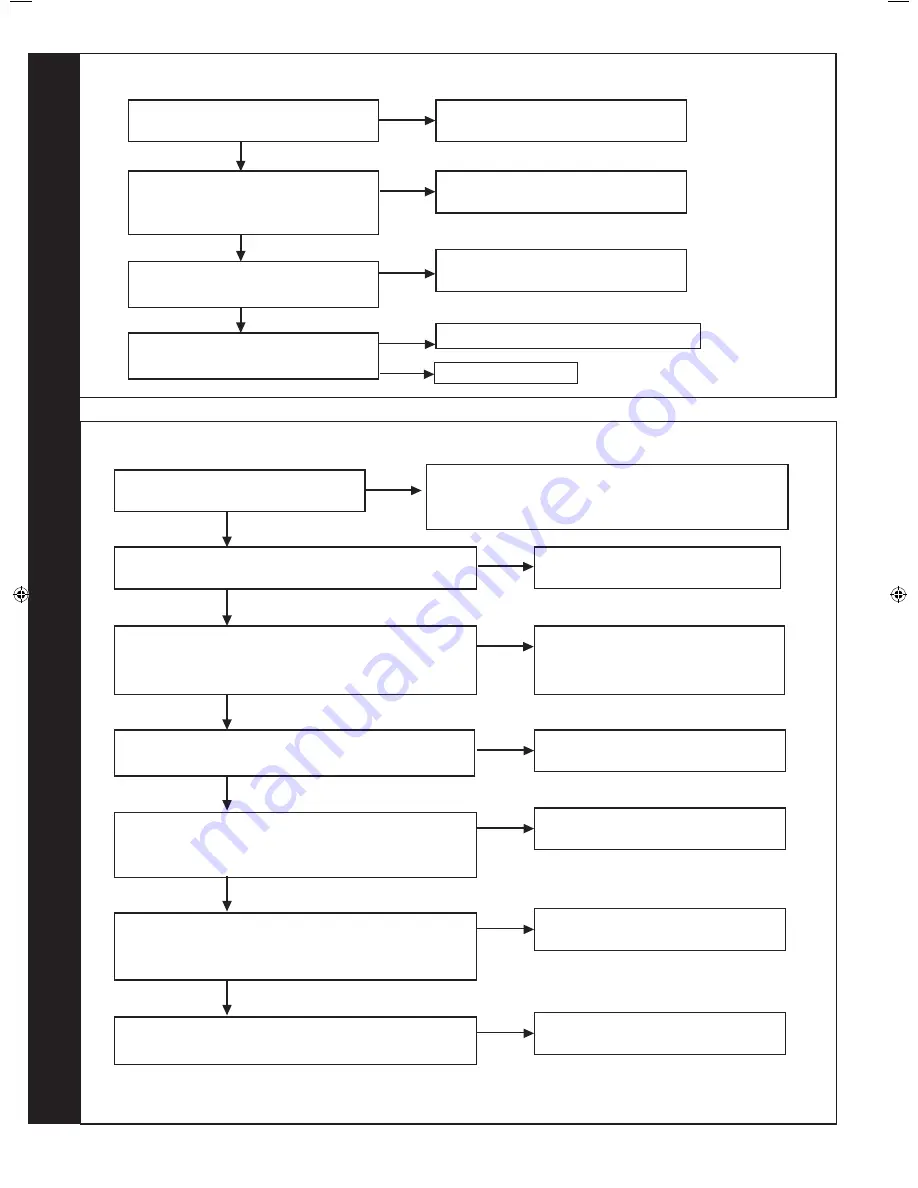

74 oVERHEAt LoCkout

Has PCB just been replaced?

Reset Boiler

yes

no

Are the boiler and CH/DHW system

filled with water and are all isolation

valves and radiator valves open?

Fill and vent the system and open all

isolation valves, then reset the boiler.

no

yes

Is the flow/return differential across

the boiler in excess of 30ºC?

Check the flow and return

thermistors (refer to Frame 80 & 81)

no

yes

Check that the pump is rotating freely.

Is the differential now below 20ºC?.

Replace the pump, then reset the boiler

no

yes

Reset the boiler

75 IGnItIon LoCkout

If the boiler is reset, does it ignite for a

short time and then extinguish?

Check the detection electrode and associated harness

for continuity, visual condition and position (refer to

Frame 67). Check if the condensate pipe is blocked.

yes

no

Is the gas pressure available at the boiler > 18mbar?

Check gas supply and rectify fault

no

yes

Is the following voltage available at the Gas Valve?

(approximately 215Vdc for 30, 40, 60, 80 and 150kW)

(approximately 240Vac for 100 and 120kW)(* See note)

Check wiring from Gas Valve to PCB

and replace if necessary, otherwise

replace the main PCB

no

yes

Unplug the Gas Valve, is the resistance between the

outside pins between 1k

Ω

and 10k

Ω?

Replace Gas Valve

no

yes

Check Spark Generator and associated Harness for

continuity, visual condition and position (refer to Frame

58). Are these functioning correctly?

Replace Spark Generator and

Harness as necessary

no

yes

Replace Ignition Electrode and

associated Harness as necessary

no

Check Ignition Electrode and associated Harness for

continuity, visual condition and position (refer to Frame

66). Are these functioning correctly?

yes

Replace Gas Valve

no

Check Syphon and condensate drain pipework for blockage

and rectify if necessary. Boiler now working OK?

* Note: due to the wave form of the rectified voltage, the reading will vary depending on the type of meter used to measure the

value. In general terms a reading of greater than 150V indicates that the correct voltage is supplied to the gas valve.

206210-3.indd 52

09/06/2011 13:34:59