SERVICING

30

Mini

--- Installation & Servicing

35 SERVICING SCHEDULE

To ensure the continued safe and efficient operation of the

appliance it is recommended that it is checked at regular

intervals and serviced as necessary.

The frequency of servicing will depend upon the installation

condition and usage but should be carried out at least

annually.

It is the law that any service work must be carried out by a

registered CORGI installer.

In IE, servicing work must be carried out by a competent

person.

1 Turn the heating controls to maximum so that the boiler

lights and remains running. Check that no other gas

appliances in the house are in use or likely to be used.

2 When the boiler has settled down check the gas rate at

the meter (if the meter is of the pointer type you should

time only complete revolutions of the pointer). Check the

gas rate against the figures given in Table 2 for CH

operation.

3 For a combination boiler, fully open a hot water tap. When

the boiler has settled down check the gas rate, as in step

2, checking the measured rate against the figures given in

Table 3 for HW operation.

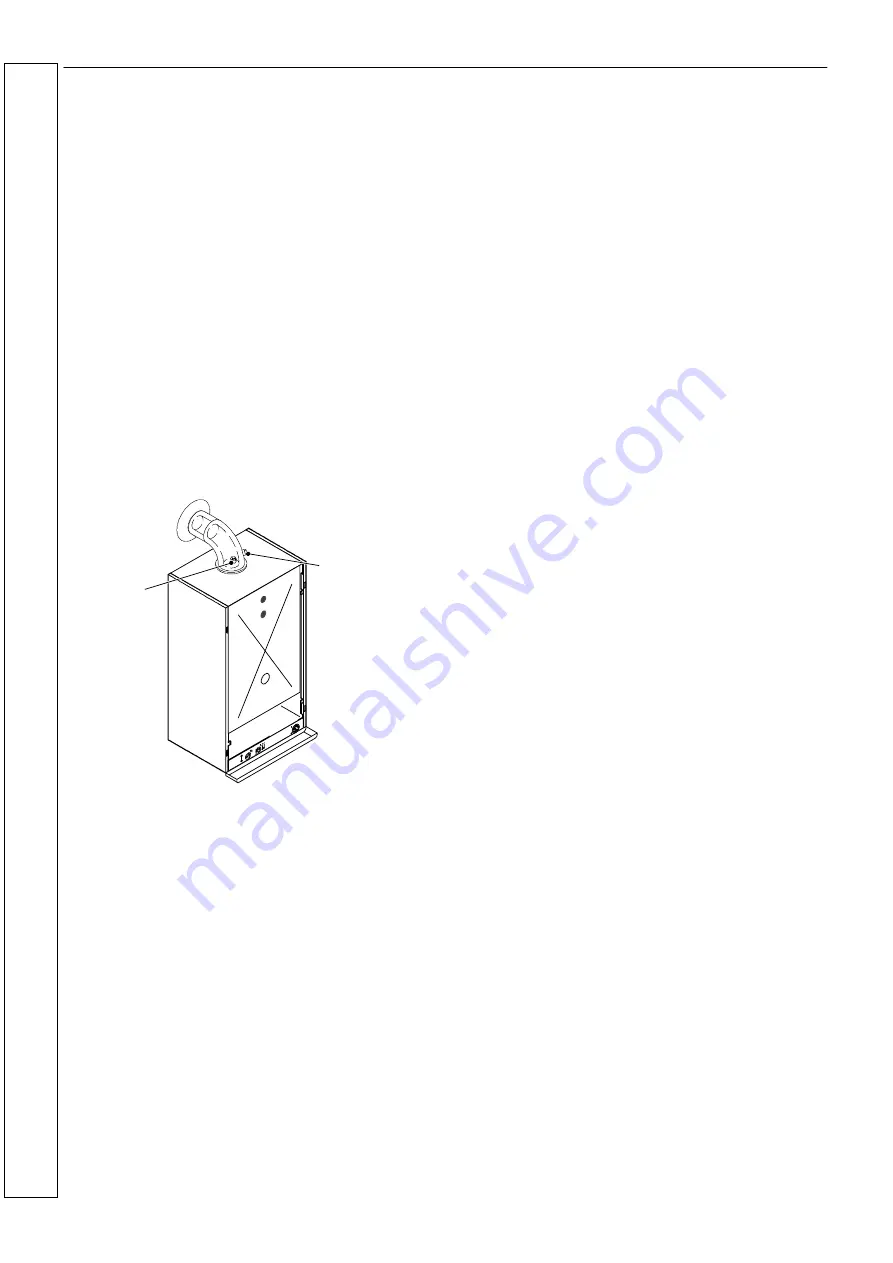

4 Run the boiler and check the percentage of CO and CO2

in the flue gasses at the sampling point indicated in the

following drawing.

Air intake

sampling point

Exhaust gas

sampling point

Note. If your meter reads CO in parts per million the figure

must be divided by 10,000 to convert it to a percentage.

5 If the ratio of CO/CO

2

is less than ,004 and the gas rates

measured in steps 3 and 4 are close to nominal then no

further action need be taken. If not, proceed to step 6.

6 Clean the main burner.

7 Clean the heat exchanger.

8 Check the injectors for blockage or damage.

9 Check that the flue terminal is unobstructed.

The servicing procedures are covered more fully in Frames 36

to 41 and MUST be carried out in sequence.

WARNING.

ALWAYS turn off the gas supply at the gas service cock, and

switch off and disconnect the electricity supply to the

appliance before servicing.

Switching the boiler on/off switch ‘off’ does not fully

isolate the boiler.

ALWAYS test for gas soundness and carry out functional

checks on reassembly.

IMPORTANT

. When work is complete the boiler inner front

sealing panel MUST be correctly refitted, making a good seal.

DO NOT OPERATE THE BOILER IF THE SEALlNG PANEL

IS NOT FITTED.

Complete the service section in the Benchmark

Commissioning Checklist.

SER

VI

CI

N

G